Automobile Roof: History & Design

The car top or automobile roof of an automobile is the part of the vehicle situated above the passenger compartment, shielding the vehicle occupants from external elements such as sun, wind, and rain.

When did cars start having roofs?

Initially, cars lacked roofs altogether. Subsequently, these early vehicles being influenced by the era of horse-drawn carriages. Early car roofs adopted similar materials and designs, incorporating folding canvas tops, some equipped with transparent side curtains. in 1905 Cadillac then marked a significant milestone by being the first manufacturer to introduce fully enclosed factory bodywork.

However, a demand for something intermediate arose, prompting a European response. By the 1920s consumers could by vehicles with roof openings covered in either canvas or metal, along with the patented Pytchley sunroof mechanism. In 1933, Hillman went a step further by presenting a sliding roof panel featuring glass windows on the Aero. In the present day, a variety of roof options, such as sunroofs, moonroofs, panoramic roofs, T-tops, or targa tops, are readily available on most new vehicles, each providing a middle ground between a fixed roof and a complete convertible.

What was the first hard top convertible?

A convertible or cabriolet is a type of passenger car that can be operated with or without a roof. The techniques for retracting and storing the roof differ across different time periods and manufacturers.

The design of a convertible car enables an open-air driving experience, offering the flexibility to have a roof when needed. One potential drawback of convertibles is the diminished structural rigidity, which necessitates substantial engineering and modifications to compensate for the impact of removing the car’s roof. In 1935 Peugeot 402 Eclipse Decapotable is recognized as the first car featuring a folding hardtop roof.

What was the first car with a glass roof?

Sunroofs and moonroofs in automobiles have a lengthy history. The initial car equipped with a sunroof was produced in 1937, and the first moonroof was introduced in 1973, featured in the Lincoln Continental Mark IV of that model year. However, the first instance of a full panoramic roof was integrated into the 1953 Lincoln XL-500 concept car, showcasing a Plexiglas bubble canopy that extended the full length of the vehicle.

Automotive roof design overview

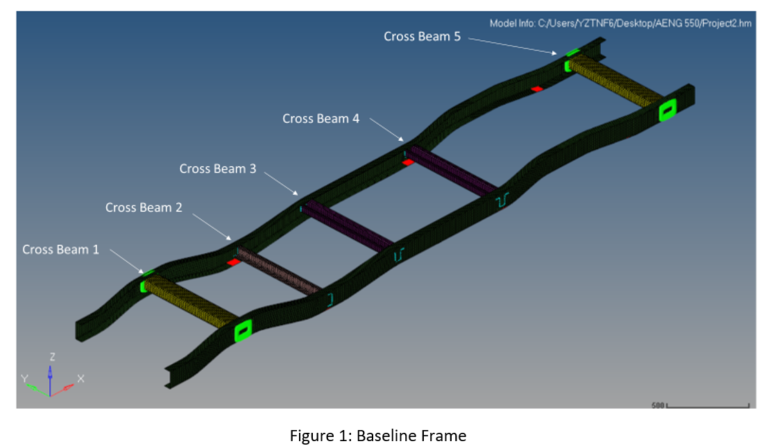

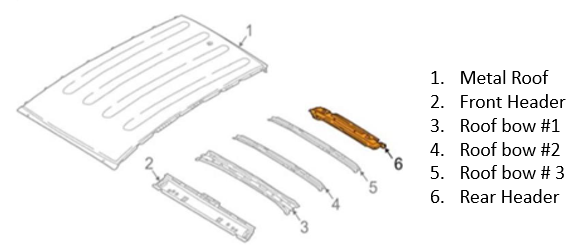

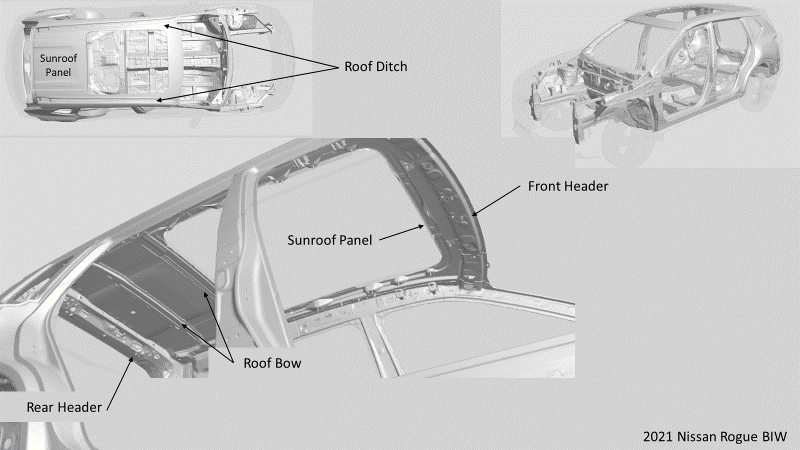

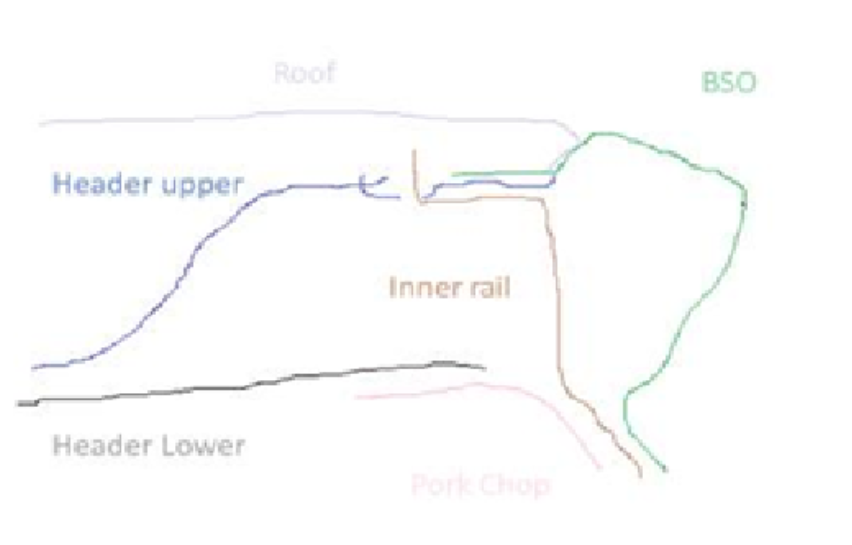

The roof is not a singular component on a vehicle; rather, it comprises the Front Roof Rail (front header), Rear Roof Rail (rear header), Bow Roof Rail, and Center Roof Rail. These Bow Roofs are positioned in the flattest section of the panel. The Rear Roof Rail connects with the Back door and Body side outer, while the Front Roof Rail interfaces with the Windshield glass and body side outer.

What is automobile roof design?

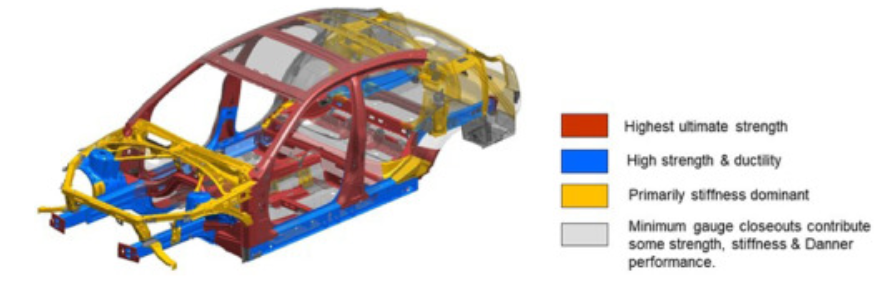

When designing an automobile roof, automotive engineers must balance engineering and artistic design requirements while adhering to the federal safety standard requirements, roof crush (FMVSS 216a). Even though the body structure of a vehicle is composed of many parts, not all of them carry equal loads. The class A roof outer panel is made from thin lower-strength material, which is more ductile and better at forming shapes to help enable the vehicle styling theme.

Underneath the roof outer panel of the vehicle is all the main load-carrying members which are made from varying grades of high-strength steel. As federal requirements become more stringent and demand automakers to fabricate vehicles that are more fuel-efficient automakers are becoming more creative in ways to cut mass while still meeting all vehicle requirements.

What is the use of a car roof?

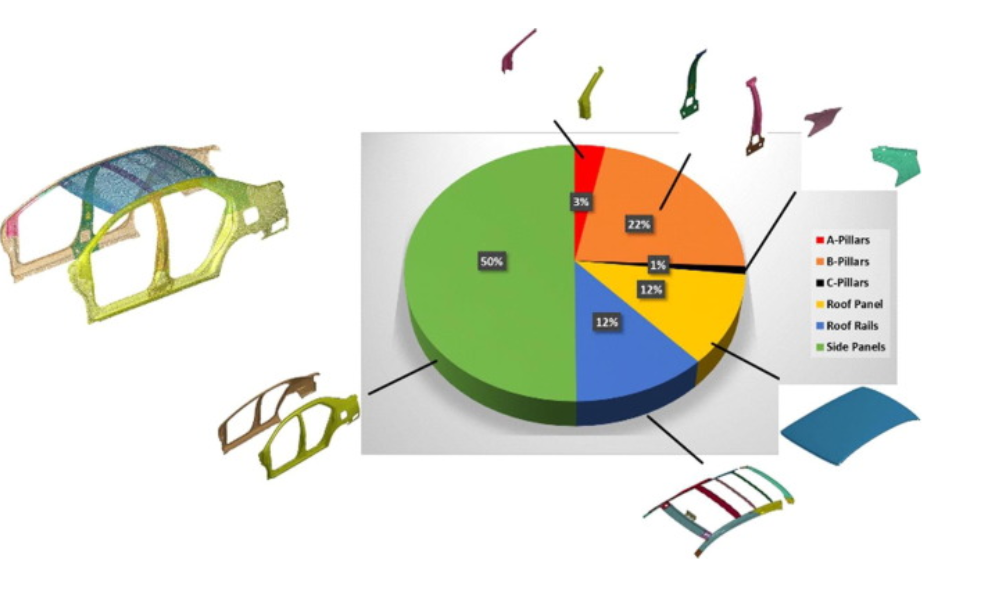

An automobile roof or roof panel is part of the body structure and body-in-white upper structure subsystem. The body structure is made up of 31 parts which can be divided into six core groups: A-Pillars, B-Pillars, C-Pillars, roof rails/roof ditch, roof panel assembly and side panels (front, side, and rear closures) [8]. The roof panel assembly works with the rest of the BIW structure to protect the occupants in case of an impact by directing the load and forces away from the occupant.

What are the different types of car roofs:

There are various types of automobile roof variants, from traditional all-metal roofs to convertible roofs to sunroofs and moonroofs. The differences in the types of sunroofs will not be explored as they are very similar from an integration and packaging perspective. Both sunroofs and moon roofs have electrically adjustable sunshades that open and close. Currently, the hot new thing which automakers have started to experiment with is integrating large glass panels on all-glass roofs.

What components make up a automobile roof?

The roof panel assembly is made up of different components depending on what variation of roof you may be dealing with, but the most common components are front and rear headers, roof bows, roof ditch/roof rails (roof ditch modeling execution), sunroof module, sunroof ring (only applicable to sunroof vehicles), and the roof outer panel /glass roof.

What is a greenhouse in a car?

The roof system and glass windows (windshield, rear/side windows) are part of the green-house. The purpose of the greenhouse is to act as a barrier for the occupants from inclement weather. In sunlight these components warm up your car similar to a greenhouse, thus that is how this area of a car got its name.

Why are most automobile roofs curved?

Automotive roofs are designed to have a slight crown, with a peak around the B-Pillar. In addition to improving aerodynamic performance (fuel economy/range), the reasonings behind this is that the roof is designed to act as a water management system for the vehicle. During a storm, the water is redirected in the roof ditch to the front and back of the vehicle and away from the door openings.

The BIW system of a vehicle is like the foundation and frame of a house. All other components mount to the body-in-white and the roof is no exception. The roof is the mounting surface for many parts such as the headliner and substrate, electrical harnesses, airbags, grab handles, sunshade, sun visors, an overhead console, and radio antenna. Each of those components has specific packaging requirements which the roof must enable. Accessories such as roof racks also attach to the roof.

How does the automobile roof affect the aerodynamics of a car?

The roof is also an important player in achieving the desired aerodynamic performance. For optimal aerodynamic performance, it is best for the air to stay attached as it goes over the roof. Premature separation would cause extra turbulence which would increase the overall vehicle drag and reduce fuel economy or range. Roof-mounted accessories such as roof racks also increase drag by increasing the frontal area of a car and increasing the drag coefficient thus reducing a car’s aerodynamic performance.

Why do SUVs have ridges on the roof?

Since the roof panel is also part of the vehicle’s class A surface, in addition to all the engineering, performance, and integration requirements the roof is also expected to be aesthetically pleasing. The artistic staff works hand in hand with engineers to make sure the design of the roof meets all best practices and manufacturing requirements but also matches the rest of the vehicle’s theme.

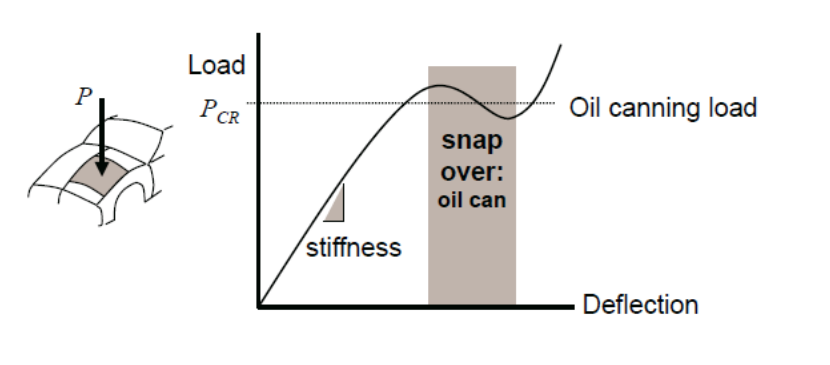

The grooves or ridges sometimes seen on the roof of SUVs are artistically styled stiffening beads. These stiffening beads are added to strengthen the roof panel to prevent oil canning. These stiffening beads run fore-aft (front to back) and are usually spaced 250mm – 300mm (9in -12in) apart to reduce/eliminate any aesthetic defects in the panel such as rippling, waviness, or buckling which is can be noticed in large flat cold-rolled sheet metal parts.

What is oil canning in automotive panels?

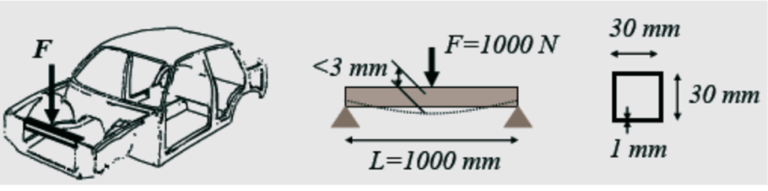

Sometimes when you press down on a hood or roof panel of a car you will hear a pop, bang, or clunking noise. This noise is due to the load on a large panel exceeding the critical buckling load Pcr and as a result, reversing the curvature of the panel. Automotive panels are generally doubly curved. The curvature on these automotive panels is not the same in the orthogonal direction. The greater the stiffness of the panel the greater the oil-canning resistance. The way to increase the Pcr for a roof panel is by improving the panel geometry/curvature, and support conditions, and by adding roof bows.

How do you measure an automobile roof strength?

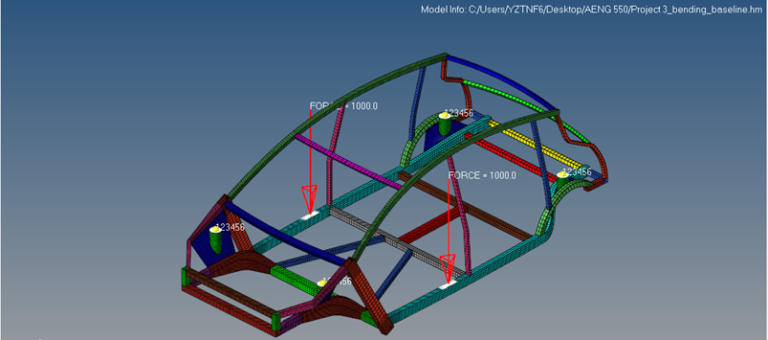

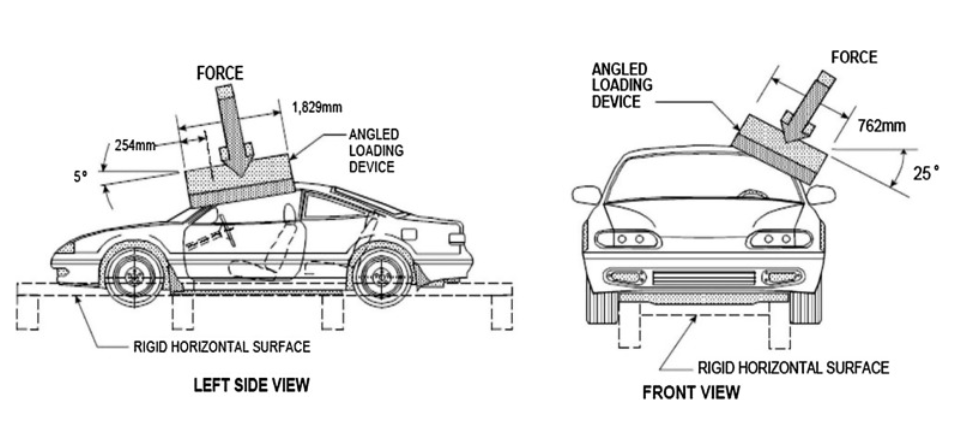

According to the Federal Motor Vehicle Safety Standard (FMVSS), rollover crashes are some of the most dangerous automobile accidents. About 35% of occupants involved in rollover crashes die, which is more than 7500 people a year. This is because seatbelts on passenger seats are not effective at protecting occupants during a rollover because of their geometry. [8]

As a result, the FMVSS has developed a standardized test to check vehicle roof structure performance. The latest standard, FMVSS 216a, states that a vehicle that weighs over 6,000 pounds, should be able to withstand a force equal to 3 times the unloaded vehicle weight (UVW) without the roof collapsing (less than 5 inches of deformation). This test also needs to be conducted on both driver and passenger sides. [8] Since the loading platen is placed forward of the C pillar, the main load-bearing structures during a roof crush test are the A-pillars, B-pillars, front header, and roof rails [7].

How strong is a car roof?

When you talk about an automotive roof most people associate it with the exterior skin however even though the roof panel might be the largest component in the roof system it does not carry or absorb major loads. The exterior skin of the roof only absorbs 12% of the loads during the event of a side impact crash making it one of the weaker structural members [8].

High-strength steel (HSS) has earned rising popularity in the modern automobile industry for manufacturing structural members because of its outstanding performance and mature manufacturing technology. The main structural members of the roof are the headers and roof ditch/roof rails. Since these are main load-bearing structural components, they are commonly made from HSS, such as press-hardened steel, to limit roof crush in the event of a rollover or side impact [1][2].

How much force can a car roof withstand?

During an accident, the forces from the impact are transferred from the B-pillar to the rocker and the roof side rails. If the roof rails are not made from strong enough material, significant intrusion into the upper structures would compromise headspace and lead to serious occupant injury. This space is so crucial that all major automotive companies have incorporated side curtain airbags to help protect the passenger [1][5].

In the event of a side impact accident, the front and rear headers also act as the primary load paths between both the BSO of the vehicle redirecting loads to the other side of the vehicle and away from the occupants. In the event of a rollover, the headers also provide additional rigidity to the roof to prevent collapse of the roof. By keeping the roof-to-windshield interface intact, the front header also plays an important role in reducing the likely hood of occupant ejection during an accident. [3]

Even though the primary purpose of the roof bow is to stiffen up the roof and prevent any fluttering during high vehicle speeds, if loads are high enough, the roof bow can come under load. In this circumstance, the roof bow would support the front and rear headers in order to provide additional reinforcement to the roof side rails and transfer the load to the other side of the vehicle and away from the primary load path. [1]

How thick is the metal on a automobile roof?

Most of the roof panels are made from thin lower carbon and bake-hardened steel panels which traditionally have been less than 1.5mm thick. However, to reduce weight and to help enable class-A styling the vast majority of roofs on new cars are only 0.75mm thick. [1].

The manufacturing process of automobile roofs:

The exterior automobile roof panel is made of one large sheet of metal known as a blank which is stamped in a press. If the vehicle has a sunroof then the sunroof opening is cut out in the midst of the stamping operation. The formed roof is then sent to the body shop where all the parts of the body structures will come together. During the initial assembly process, the BIW is held together with small toy tabs placed throughout the structure.

These toy tabs act as mechanical fasteners which hold the vehicle together while a robot starts to weld the load-bearing structural members together. The front and rear headers play a crucial part in holding the left and right body side outers (BSO) of the vehicle together during this initial assembly process. The roof panel is commonly one of the last parts of the BIW which is welded onto the vehicle. To reduce complexity in the assembly process, the roof is top-loaded onto the BIW. Once placed on the top of the roof ditch the roof panel is laser brazed on.

laser brazing the roof panel on the car:

In recent years laser brazing the roof panel onto the vehicle body has become increasingly popular since using this manufacturing technique provides a cleaner look by eliminating the need for roof ditch molding. During laser brazing, nonferrous metals such as bronze alloy are used as filler material. Usually, brazing uses lower temperatures than other welding techniques, which reduces the heat-affected zone and potential damage to the parts being welded. In laser brazing, only filler material melts and joins the joining material. [6] When using the proper technique, you can achieve the same tensile strength of MIG welding by using the laser brazing process and it is less harmful to the parts and easier to control. [6]

What is the outside body of a car called?

The “Class A body panels” or exterior closure panels of the vehicle provide little to no structural support. As a result, they are made from lower carbon steel which is more ductile and can be stamped and formed in complex shapes to meet studio styling requirements. Some automakers will use high-strength bake-harden and dual-phase steels on these exterior closure parts, but it is only to improve dent resistance. [1]

An example of the A surface exterior closure body structure parts would be the quarter panels, fenders, exterior door panel, and exterior roof panel.[1] These lower-strength panels are then reinforced with high-grade steel brackets, reinforcements, and cross members which give the body structure its strength and rigidity. Unlike the class A surfaces these reinforcements and cross members are made from thicker sheet metal.

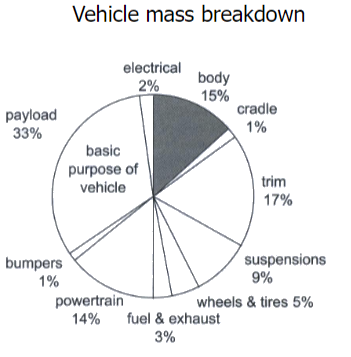

What makes a car heavy?

With a cultural shift to electrification and green energy, automotive companies are looking at how they can manufacture more environmentally conscience vehicles. The body structure of a vehicle is one of the main contributors to overall vehicle mass, accounting for around one-third of overall vehicle mass. The body-in-white (BIW) makes up nearly a quarter of the vehicle mass by itself. Reducing the overall vehicle mass while not jeopardizing current vehicle structural performance (crashworthiness) would tremendously benefit an automotive company in meeting the crash, emission, and weight standards set by federal regulatory bodies. A lighter-weight vehicle would reduce emissions while increasing fuel economy for a traditional internal combustion engine vehicle and increasing the range for a battery electric vehicle.

References

- C.D. Horvath, Chapter 2 – Advanced steels for lightweight automotive structures, Editor(s): P.K. Mallick,In Woodhead Publishing in Materials, Materials, Design and Manufacturing for Lightweight Vehicles (Second Edition), Woodhead Publishing, 2021, Pages 39-95, ISBN 9780128187128, https://doi.org/10.1016/B978-0-12-818712-8.00002-1 (http://www.sciencedirect.com/science/article/pii/B9780128187128000021)

- Cui, A., Xu, X., Sun, W., Yang, W., Huang, X., & Liu, T. (2020). Study on crashworthiness optimization of carbon-fiber sandwich panel structure with polypropylene foam core. [基于耐撞性的碳纤维/聚丙烯泡沫夹芯板结构优化研究] Qiche Gongcheng/Automotive Engineering, 42(6), 840-846. doi:10.19562/j.chinasae.qcgc.2020.06.020

- Konrad M. Dobbertin, et all, The relationship between vehicle roof crush and head, neck and spine injury in rollover crashes, Accident Analysis & Prevention, Volume 58, 2013, Pages 46-52, ISSN 0001-4575,

- https://doi.org/10.1016/j.aap.2013.04.020. Jeong-Min Lee, Byung-Min Kim, Dae-Cheol Ko, Development of vacuum-assisted prepreg compression molding for production of automotive roof panels, Composite Structures, Volume 213, 2019, Pages 144-152, ISSN 0263-8223, https://doi.org/10.1016/j.compstruct.2019.01.092. (http://www.sciencedirect.com/science/article/pii/S0263822318315009)

- Mahmood, H. F., & Baccouche, M. R. (1996). Design of automotive body structure for roof crush. American Society of Mechanical Engineers, Applied Mechanics Division, AMD, 218, 25-32. Retrieved from www.scopus.com

- Muthuraju, K., & Lakshmankumar, A. (2020). Experimental studies of different thick steel sheets and variable clearance in MIG brazing. Paper presented at the IOP Conference Series: Materials Science and Engineering, , 912(3) doi:10.1088/1757-899X/912/3/032078 Retrieved from www.scopus.com

- M.R. Bambach, Fibre composite strengthening of thin steel passenger vehicle roof structures, Thin-Walled Structures, Volume 74, 2014, Pages 1-11, ISSN 0263-8231, https://doi.org/10.1016/j.tws.2013.09.018. (http://www.sciencedirect.com/science/article/pii/S0263823113002401)

- Soroosh Borazjani, Giovanni Belingardi, Development of an innovative design of a composite-sandwich based vehicle roof structure, Composite Structures, Volume 168, 2017, Pages 522-534, ISSN 0263-8223, https://doi.org/10.1016/j.compstruct.2017.02.015. (http://www.sciencedirect.com/science/article/pii/S0263822317302052)

- UK project develops carbon/flax hybrid automotive roof, Reinforced Plastics, Volume 60, Issue 1, 2016, Page 6, ISSN 0034-3617, https://doi.org/10.1016/j.repl.2015.12.067. (http://www.sciencedirect.com/science/article/pii/S0034361715008796)

Definitions/Abbreviations

BSO Body side outer

CFRP Carbon fiber reinforced plastic

HSS High strength steel

SWR UVW Strength to weight ratio Unloaded vehicle weight