The Future of Transportation: Exploring Hybrid Hydraulic Vehicles

You may have heard of hybrid cars that use a combination of gasoline and electricity, but have you ever heard of non-electric hybrid vehicles? Hybrid Hydraulic Vehicles (HHV), are an alternative to a regular hybrid electric vehicle that can sometimes be more beneficial than an electric hybrid vehicle. It’s pretty cool, and I’m excited to explore the future of transportation with you all. Let’s dive in!

What are Hybrid Hydraulic Vehicles?

So, what exactly are hybrid hydraulic vehicles? Well, they’re a type of transportation that combines hydraulic technology with traditional combustion engines to create a more efficient and eco-friendly mode of transportation. Essentially, they use hydraulic power alongside conventional engines to propel the vehicle and improve fuel efficiency.

Non-electric hybrid vehicles specifically, Hybrid Hydraulic Vehicles (HHV) are being considered

viable and can sometimes be more beneficial than an electric hybrid vehicle. Benefits depend very much on the drive cycle.

How does a hydraulic hybrid vehicle work?

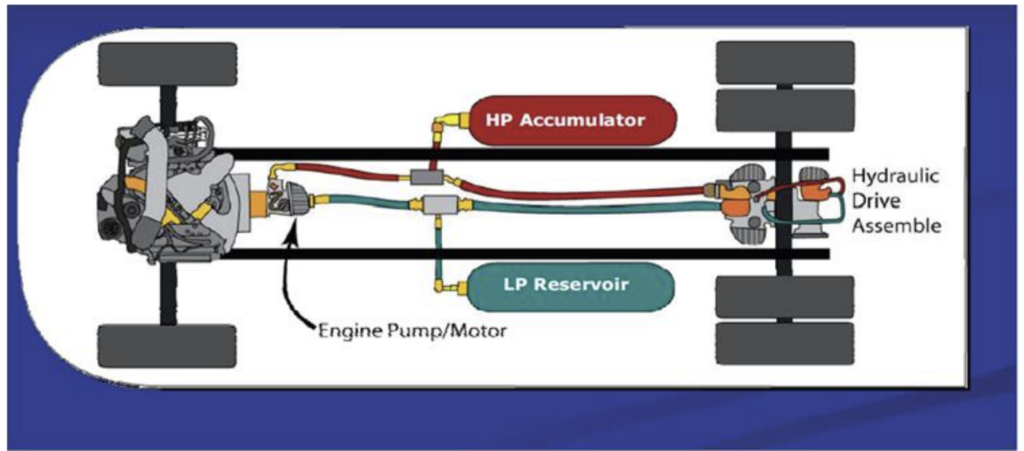

Now, let’s get into the nitty-gritty of how these vehicles work. Hybrid hydraulic vehicles use a combination of hydraulic components, such as pumps and accumulators, with a traditional internal combustion engine (ICE).

When the vehicle accelerates, the hydraulic system uses excess energy from the engine to pump hydraulic fluid into an accumulator, which stores the energy. Then, when the vehicle decelerates or needs an extra boost of power, the stored hydraulic energy is released to assist the engine, reducing the workload on the engine and thus saving fuel. The efficiency of the hydraulic pump, motor, and storage, individually can be around 90% however at the system level the efficiency is around mid-60 to 70%

The hydraulic system also allows for regenerative braking, where the energy generated during braking is converted into hydraulic energy and stored for later use. This further improves the overall efficiency of the vehicle.

How do you store hydraulic energy?

Hydraulic energy can be stored in a hydraulic hybrid vehicle using compressed air in a hydraulic accumulator/cylinder similar to how a battery stores energy in an electric system. The accumulator is typically a high-pressure container that stores hydraulic fluid under pressure. When the vehicle decelerates or brakes, the hydraulic system captures the excess energy and stores it in the accumulator by pressurizing the hydraulic fluid. To pressurize the gas, power/ energy from the IC engine is used to activate the hydraulic pump. This stored hydraulic energy can then be extracted through a hydraulic motor during vehicle acceleration or to assist the engine, improving fuel efficiency and reducing emissions. Hydraulic accumulators are designed to be compact and durable, allowing for efficient storage and release of hydraulic energy in the vehicle’s powertrain system. Pressure in high pressure (HP) cylinder and the pipeline can be as high as 3000 to 5000 psi while in the low-pressure (LP) cylinder and the corresponding pipeline can be a few hundred psi.

how do hydraulic hybrid vehicles compare to electric hybrid vehicles?

Hydraulic hybrid vehicles and electric hybrid vehicles are both types of hybrid vehicles that aim to improve fuel efficiency and reduce emissions. However, they differ in their power storage and propulsion systems. Hydraulic hybrid vehicles use a hydraulic system to store and release energy, while electric hybrid vehicles use an electric battery system. Hydraulic hybrid vehicles tend to be more efficient in stop-and-go driving conditions think about a school bus or your local Amazon delivery van, while electric hybrid vehicles may be better suited for longer distances and higher speeds. Both technologies have their advantages and limitations, and further research and development are needed to determine their full potential in sustainable transportation.

Energy stored in the hydraulic accumulator system is quite low in terms of kw-hr/kg. The specific energy density in the hydraulic accumulator can be about 1.9 kw-hr/kg. Whereas in a battery specific energy density can be e.g. 30 kw-hr/kg. The Specific power density of the hydraulic system can be of the order of 2500 watts/kg. Whereas the electrical system’s specific power density (battery) can be about 650 watts/kg.

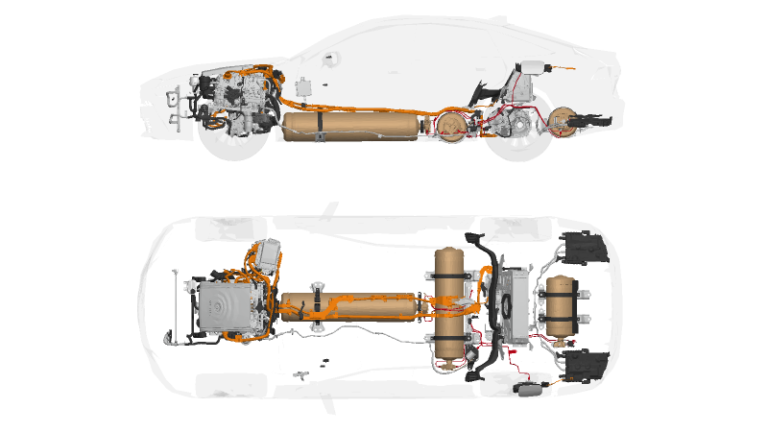

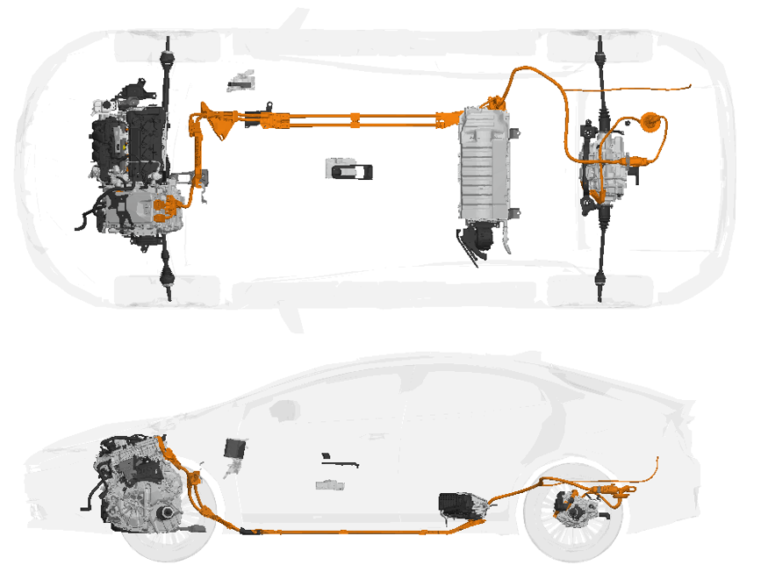

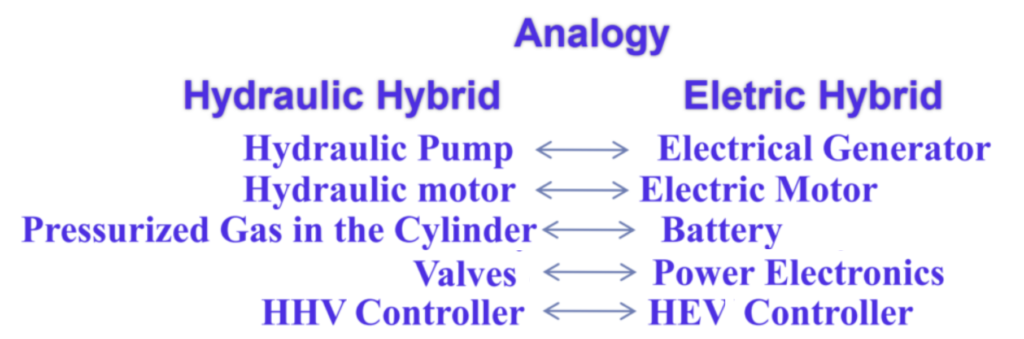

An analogy of parts between an HHV and HEV

The components in a hydraulic hybrid vehicle differ from those in an electric hybrid vehicle. In a hydraulic hybrid vehicle, the key components include a hydraulic pump/motor, a pressurized gas in the cylinder, and hydraulic lines/ values to transfer energy. These components work together to store and release hydraulic energy for propulsion. On the other hand, an electric hybrid vehicle typically consists of an electric motor/ generator, a battery pack for energy storage, and power electronics. These components work together to store and release electrical energy for propulsion. While both types of hybrids have unique components, they share the goal of improving fuel efficiency and reducing emissions.

What is hydraulic regenerative braking?

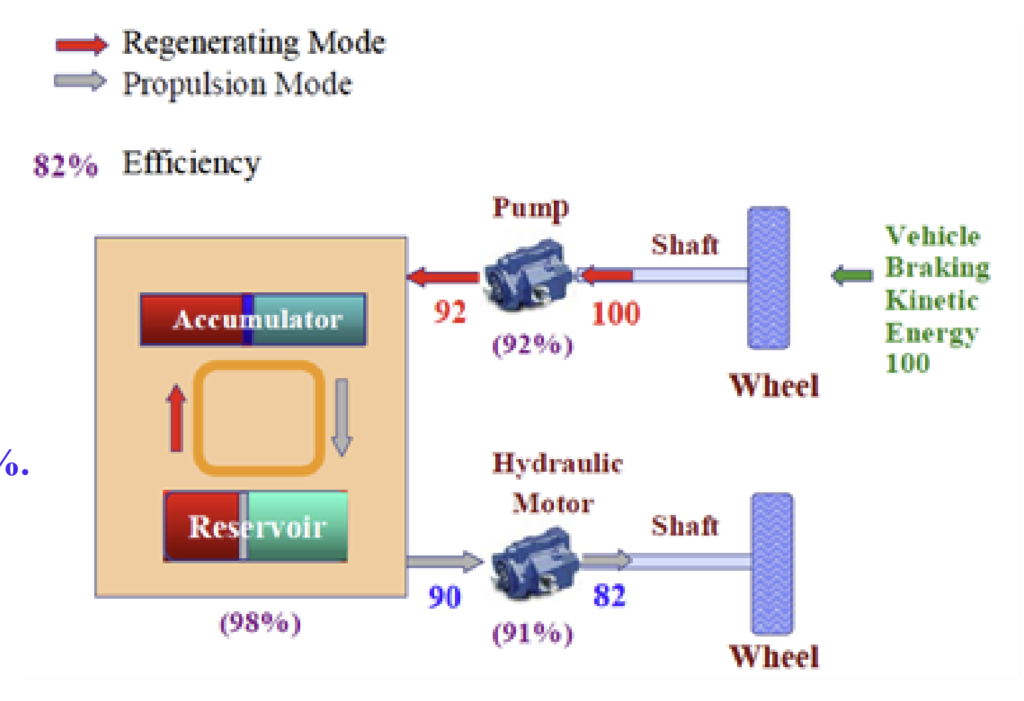

Hydraulic regenerative braking is a technology used in hydraulic hybrid vehicles that allows for the capture and storage of energy during braking or deceleration. This system can be quite adequate for storing the regenerated energy during braking since power is high but the energy involved is typically low in this situation. When the driver applies the brakes, the hydraulic system in the vehicle captures the kinetic energy from the vehicle’s motion and uses it to pressurize hydraulic fluid, which is then stored in a hydraulic accumulator.

This stored hydraulic energy can be later used to assist the engine during acceleration or power other vehicle functions, contributing to improved fuel efficiency and reduced emissions in hydraulic hybrid vehicles. Even though the hydraulic system-specific energy density or watt-hr/kg is relatively low compared to a battery. The efficiency of both the hydraulic pump and the motor is a little over 90%. The efficiency of the accumulator (HP and LP together) is about 98%. Hence the efficiency of the whole regeneration process is 82%.

Advantages and Disadvantages of Hybrid Hydraulic Vehicles

Like any technology, hybrid hydraulic vehicles have their pros and cons. Let’s take a look at some of the advantages and disadvantages.

Advantages:

- Improved Fuel Efficiency: The hydraulic system can assist the engine during acceleration and deceleration, resulting in better fuel economy and reduced emissions. IC engine can run at optimum efficiency to drive the hybrid hydraulic system to deliver energy to the wheels.

- Environmental Benefits: Hybrid hydraulic vehicles can potentially reduce greenhouse gas emissions and air pollution, making them more environmentally friendly.

- Regenerative Braking: The ability to convert braking energy into hydraulic energy for later use can further enhance fuel efficiency and reduce wear on traditional braking systems.

- High Torque: Hydraulic systems can provide high torque, which can be beneficial for heavy-duty applications such as commercial vehicles and construction equipment.

- Good when short bursts of high-power acceleration and deceleration are involved.

- The hydraulic hybrid system can be more suitable for high-power and relatively low-energy applications

- Can eliminate the need for a massive conventional transmission system.

- Hydraulic fluid can be more easily moved from one point to another without the need for an elaborate transmission gearbox

- However, this concept of transmission can be used in a regular non-hybrid vehicle as well, where only the transmission system could be hydraulic.

- To be able to drive an IC engine at its most optimum point and at the same time eliminate torque-speed pulsations at the load

- Will need some sort of storage, which can be an accumulator.

- Without storage, it is in principle possible to realize the optimum operating point of the engine by switching the valves on and off to match the average load demand. However, the output torque speed at the load will then be pulsating, which can be smoothed by using a flywheel etc.

Disadvantages:

- Cost: Hybrid hydraulic vehicles may be more expensive to manufacture and purchase compared to traditional vehicles due to the additional hydraulic components and technology.

- Maintenance: The hydraulic system requires specialized maintenance and can be complex to repair, which may increase maintenance costs.

- Weight and Size: The hydraulic components and accumulators may add weight and take up packaging space in the vehicle, potentially affecting cargo capacity and overall vehicle design.

- Limited Market Availability: Hybrid hydraulic vehicles are still in the early stages of development and may not be as widely available in the market compared to traditional vehicles.

- Energy stored in the hydraulic accumulator is rather low, this option cannot continue too long, due to the excessive gas pressure needed in the accumulator making it difficult to sustain.

- If the HP accumulator cannot store any additional energy, it will be necessary to change the engine operating point, so as to match the propulsion needs.

- Alternatively, Stop the engine for a short while thus using the energy from the hydraulic accumulator, and start the engine again once the pressure in the accumulator has decreased.

The Potential Impact of Hybrid Hydraulic Vehicles on the Environment

One of the most exciting aspects of hybrid hydraulic vehicles is their potential impact on the environment. As long as the average power consumption by the (hydraulic) motor is the same as the average power delivered by the engine, the process is sustainable, with transients absorbed by the accumulator. As concerns about climate change and air pollution continue to grow, finding sustainable solutions for transportation is becoming more important than ever.

Hybrid hydraulic vehicles have the potential to reduce greenhouse gas emissions and air pollution. By utilizing the stored hydraulic energy during acceleration and deceleration, these vehicles can reduce the workload on the engine, resulting in improved fuel efficiency and lower emissions. Additionally, the regenerative braking feature allows for the recapture of energy that would have been lost during braking, further contributing to the overall environmental benefits.

In urban areas, where vehicles often experience frequent stops and starts, hybrid hydraulic vehicles can be especially beneficial. The hydraulic system can assist the engine during stop-and-go traffic, reducing the need for the engine to work harder and consume more fuel. This can help reduce emissions and improve air quality in congested city streets.

Another potential environmental impact of hybrid hydraulic vehicles is their ability to operate on renewable energy sources. Hydraulic energy can be generated using renewable sources such as solar, wind, or hydropower, which can further reduce reliance on fossil fuels and contribute to a more sustainable transportation system.

Of course, it’s important to note that no technology is without its limitations. Hybrid hydraulic vehicles are still in the early stages of development, and their widespread adoption and impact on the environment will depend on various factors, including technological advancements, infrastructure development, and market demand.

Are Hybrid Hydraulic Vehicles the Future of Transportation?

As we’ve explored in this article, hybrid hydraulic vehicles offer a promising glimpse into the future of transportation. With their potential for improved fuel efficiency, reduced emissions, and regenerative braking, these vehicles can contribute to a more sustainable and eco-friendly transportation system.

However, it’s also important to consider the challenges and limitations that hybrid hydraulic vehicles currently face, such as higher costs, specialized maintenance, and limited market availability. Further research, development, and innovation will be needed to overcome these challenges and make hybrid hydraulic vehicles more accessible and practical for widespread adoption.

Conclusion

While hybrid hydraulic vehicles hold great promise as a sustainable transportation solution, it’s too early to definitively say if they will become the future of transportation. As technology continues to evolve and more advancements are made in the field of hybrid hydraulic vehicles, we can expect to see further improvements in their performance, efficiency, and environmental impact. It will be exciting to see how this technology progresses in the coming years and how it may shape the future of transportation.

I hope you enjoyed exploring the world of hybrid hydraulic vehicles with me. If you have any questions or thoughts, feel free to share them in the comments below. Until next time, stay curious and keep exploring the future of transportation!