X-By-Wire Systems

Introduction

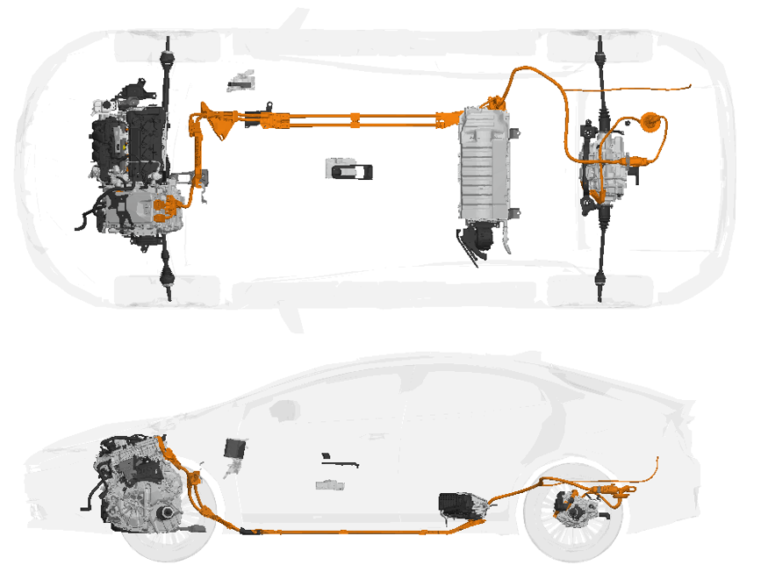

Have you ever wondered how cars work? Well, you may know that they have an engine, wheels, and brakes, but have you heard of Drive/X-By-Wire systems? X-by-wire is a term used to describe electronically controlled systems in modern vehicles, which often replace traditional mechanical or hydraulic systems. This technology utilizes electronic controls to manage brakes, steering, throttle, and gear shifts, eliminating the need for cables or hydraulic pressure. This results in fewer moving parts, increased system efficiency, faster response times, and reduced wear and tear. In this article, we’ll talk about how automotive control has evolved with the introduction of X-By-Wire systems.

Drive-By-Wire History

In the past, steering and braking a passenger car required significant physical effort. However, in the 1980s, driving became easier with the introduction of electrohydraulic assistants. The development of power steering and brake boosters further reduced the force needed for these tasks. Subsequent safety enhancements like ABS and ESC ensured that braking maintained vehicle stability. Despite these changes, the mechanical connection between the steering wheel and front wheels, as well as the brake pedal and service brake, remained, serving as a safety backup. This era is now transitioning to “by-wire” solutions, where electronic control pulses and actuators will exclusively control steering and brakes, with the steering wheel and brake pedal acting as joysticks to trigger electronic commands.

So, what are X-By-Wire systems?

Drive-by-Wiring (X-By-Wire) systems are electronic systems that replace traditional mechanical components in vehicles. They use electrical signals to control various functions of a car, such as the throttle, brakes, and steering. The need for X-By-Wire systems emerged from the desire for more precise and efficient control over a vehicle. With mechanical systems, there were limitations in how precise the control could be. For example, when you press the brake pedal, the brake pads would be applied with a certain amount of force, which may not always be enough to stop the vehicle in a safe distance. X-By-Wire systems, on the other hand, allow for more precise control over the brakes, ensuring a safer and more efficient driving experience.

Example of Brake By Wire System: NIO ET5

The history of X-By-Wire systems

The history of X-By-Wire systems can be traced back to the 1970s when aircraft manufacturers started using fly-by-wire systems. These systems replaced traditional mechanical controls with electronic signals to control the plane’s movements. The success of fly-by-wire systems in aircraft led to the development of X-By-Wire systems in cars.

x-by-wire in Aerospace (it then can be called Fly-by-Wire):

- Various control actuators (in the wing – for manipulating elevation, slowing down mechanism, and others)

- Various electrical motors throughout

While fly-by-wire is proven effective in aerospace, its application in road vehicles is challenging due to the presence of numerous dynamic objects, requiring highly accurate and rapid responses. Moreover, aircraft pilots undergo comprehensive training, giving them better intuition for such systems compared to the average driver.

When did cars start using drive-by-wire?

Cars started using drive-by-wire systems in the 1990s, when electronic controls began to replace traditional mechanical controls in vehicles. Since then, drive-by-wire technology has become increasingly common in cars, and is used in various systems, such as the brakes, steering, and throttle.

x-by-wire automotive application:

- Steer-by-wire

- Brake-by-wire

- Shift-by-wire

- Throttle-by-wire

How X-By-Wire Systems Work

There are different types of X-By-Wire systems, including brake-by-wire, steer-by-wire, and throttle-by-wire. Each system has its own set of components and functions.

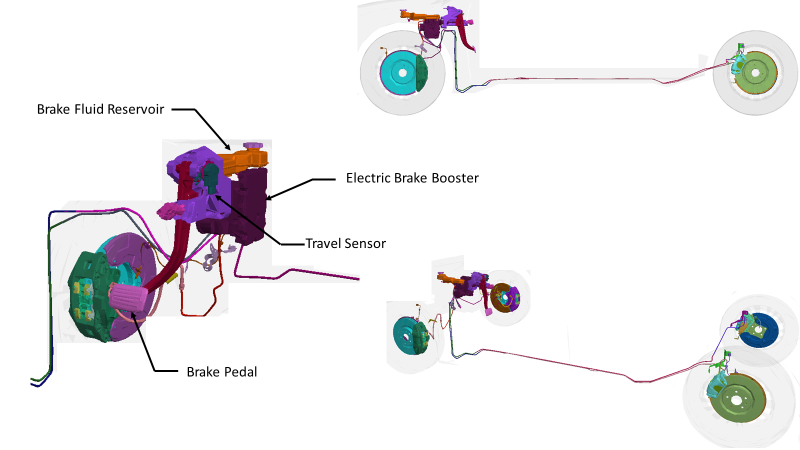

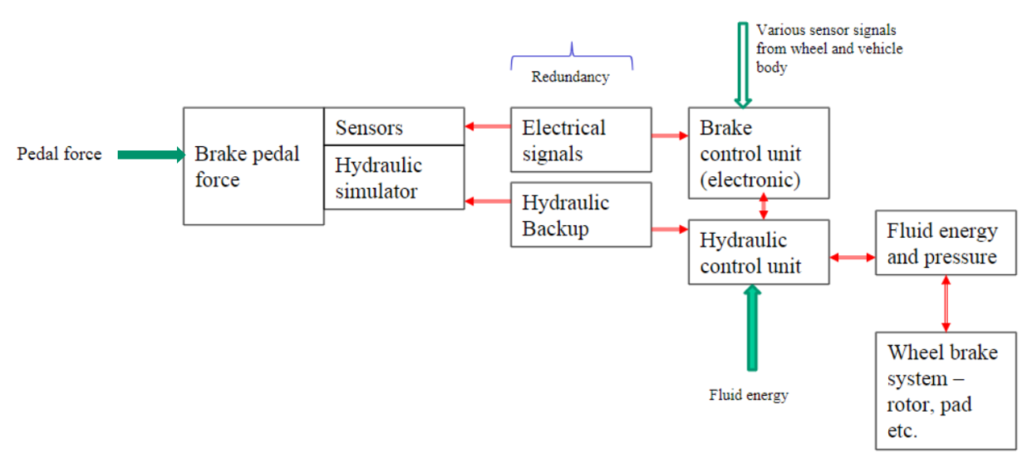

Brake-by-wire systems use electronic signals to control the brake pads’ application, replacing the traditional hydraulic system. In a brake-by-wire system, sensors detect how much force is being applied to the brake pedal and send a signal to the car’s computer. The computer then sends an electrical signal to the brake pads, which apply the necessary force to slow down or stop the car.

In the fully electro-mechanical brake (no hydraulic) everything is electrical and pedal feel to the driver can be artificially generated my some mechanical actuator system.

Brake by wire

In a pure brake-by-wire system, hydraulics are entirely replaced by motors that control the calipers and wheel locking. This differs from current technology, where braking force is generated by creating hydraulic pressure in the brake lines.

Shift by wire

The vehicle’s direction of motion (forward or reverse) is determined by sending electronic commands to the actuators inside the transmission. These commands are based on the driver’s input, which includes selections such as Park, Reverse, Neutral, or Drive.

Steer by wire

Steer-by-wire systems replace the traditional mechanical steering column with an electronic system. In a steer-by-wire system, sensors detect the position of the steering wheel and send an electrical signal to the car’s computer. The computer then sends an electrical signal to the wheels, which turn in the direction desired by the driver.

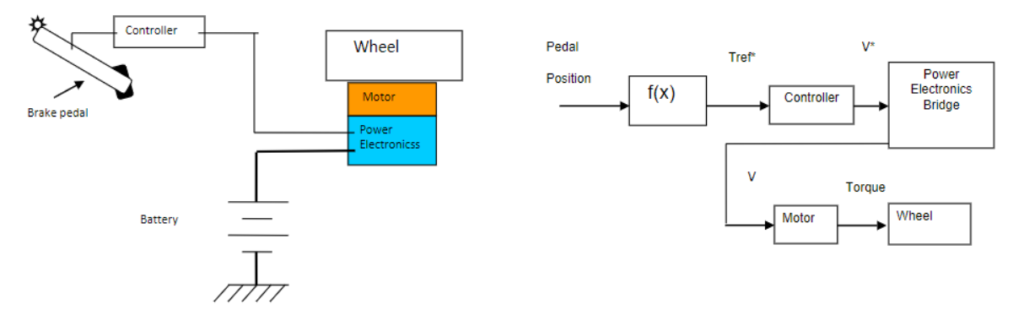

Throttle by wire

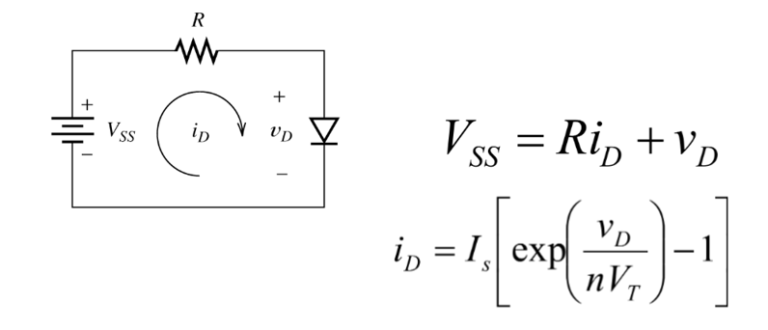

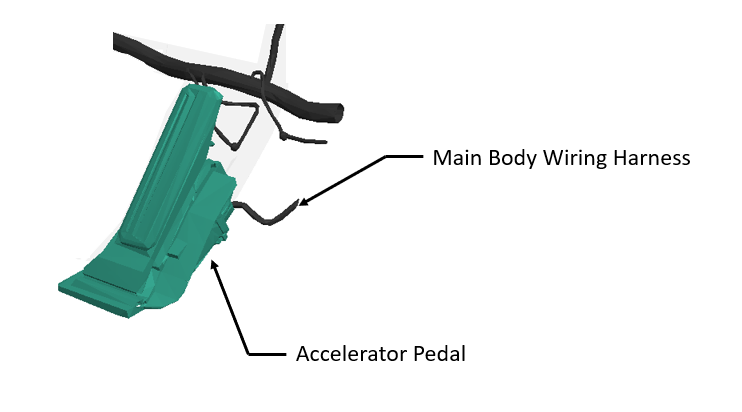

Throttle-by-wire systems use electronic signals to control the engine’s throttle, replacing the traditional mechanical linkage between the accelerator pedal and the throttle body. In a throttle-by-wire system, sensors detect how much force is being applied to the accelerator pedal and send a signal to the car’s computer. The computer then sends an electrical signal to the throttle body, which opens or closes to adjust the engine’s speed.

Is brake-by-wire safe?

Brake-by-wire systems are generally considered safe when designed and implemented correctly. These systems use electronic sensors to detect how much pressure is being applied to the brake pedal and send a signal to the car’s computer to activate the brakes. The simulator provides some feel to the driver brake pedal, thus most drivers wont even feel the difference between a regular brake system and a brake-by-wire system.

If designed correctly, brake-by-wire systems can be more precise, efficient, and responsive than traditional mechanical brake systems. Incase of a electrical system failure, brake-by-wire systems have redundant hydraulic system connection between pedal and controller can be utilized as backup to provide braking and ensure passenger safety.

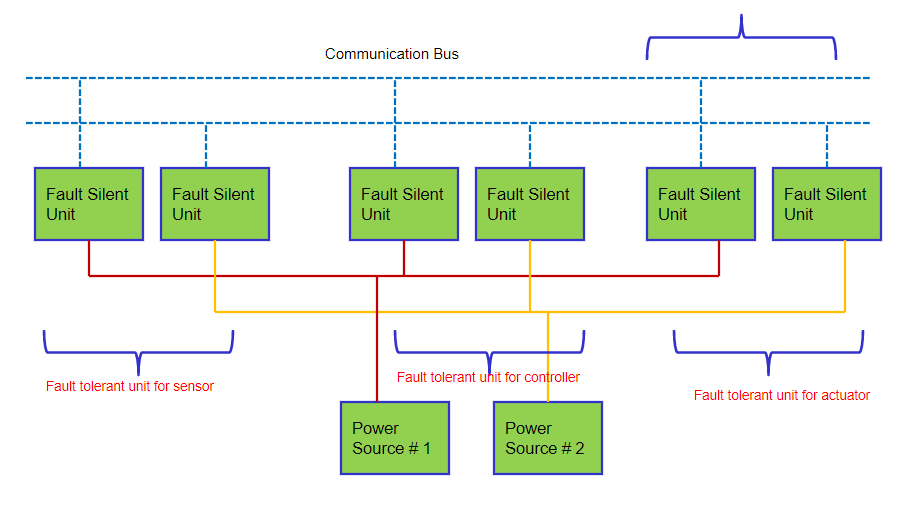

What Is fault tolerance in a brake-by-wire system?

Safety critical systems like brake by wire needs to be fault tolerant (fail safe) to ensure the safety of the occupants in the event of a failure. In order to implement fault tolerance properly, redundancy is needed some redundancy can be hardware however software redundancy may also be needed as well. This is achieved through multiple sensors, actuators, and control units being used in the system, and by implementing backup systems that can take over in the event of a failure.

Fail silent is when the failed unit is taken out automatically and does not affect other systems, and back up system takes over Fault tolerance is essential in ensuring the safety and reliability of brake-by-wire systems.

Communication bus in x by wire system

- For safety critical X by wire systems it is important to have reliable means for network communication

- Time triggered protocol TTP/C provides guarantee of availability compared to CAN

- FlexRay is also suggested by some – suitable for brake by wire

- It can also work in conjunction with existing CAN system

- Directly hardwired system is possible, but that will make the wiring more complex.

Advantages and Disadvantages of X-By-Wire Systems

X-By-Wire systems offer several advantages over traditional mechanical systems. For example, X-By-Wire systems can be more precise, efficient, and responsive than mechanical systems. In a brake-by-wire each wheel brake pressure can be independently provided thus providing more flexibility then a traditional braking system. X-By-Wire systems can also reduce weight and complexity in a vehicle, leading to better fuel efficiency and lower emissions.

However, X-By-Wire systems also have some disadvantages. One of the main disadvantages is safety concerns. In a traditional mechanical system, a failure in one component would not necessarily affect the performance of other components. In an X-By-Wire system, a failure in one component could affect the performance of the entire system, leading to potential safety hazards.

X-By-Wire Systems in Different Types of Vehicles

X-By-Wire systems are used in various types of vehicles, including passenger cars, commercial vehicles, and military vehicles. In passenger cars, X-By-Wire systems are used to improve safety and comfort. For example, some luxury cars use steer-by-wire systems to provide a smoother and more responsive driving experience.

In commercial vehicles, X-By-Wire systems are used to improve efficiency and reduce costs. For example, some trucks use throttle-by-wire systems to optimize fuel consumption and reduce emissions.

In military vehicles, X-By-Wire systems are used to improve maneuverability and survivability. For example, some tanks use steer-by-wire systems to improve their mobility in difficult terrain.

The Future of X-By-Wire Systems

X-By-Wire systems are constantly evolving, and the future looks bright for this technology. One area where X-By-Wire systems are expected to make a significant impact is in autonomous vehicles. X-By-Wire systems can provide precise and responsive control over a vehicle, making them an ideal choice for autonomous driving.

Another area where X-By-Wire systems are expected to make a significant impact is in the integration of various vehicle systems. X-By-Wire systems can be used to connect different vehicle systems, such as the engine, transmission, and brakes, allowing for better overall control and performance.

Conclusion

X-By-Wire systems have revolutionized the automotive industry by providing more precise, efficient, and responsive control over vehicles. While X-By-Wire systems offer several advantages, they also have some disadvantages and safety concerns that need to be addressed. As X-By-Wire systems continue to evolve, they are expected to play a significant role in the future of the automotive industry.