EV Braking System Explained

We all know that the braking system in a car is super important! That has never changed however, in the ever-evolving landscape of automotive technology, the advent of electrified vehicles has ushered in a new era of sustainability and efficiency.

Every electric and plug-in hybrid vehicle available in the U.S. today features a regenerative braking system. Some conventional hybrids also incorporate this technology. In this article, we will unravel the mysteries behind the energy management of electrified vehicles. Focusing on the fascinating world of vehicle braking systems and energy recuperation.

History of the Automotive Braking System

In 1899, Gottlieb Daimler, an engineer, conceived a novel concept for brakes. He proposed that a drum wrapped in cables and anchored to the car’s chassis could effectively halt a moving vehicle. Louis Renault later implemented this concept and constructed the first mechanical drum brake in 1902. This invention laid the foundation for contemporary automotive brakes.

The Braking System in a Car

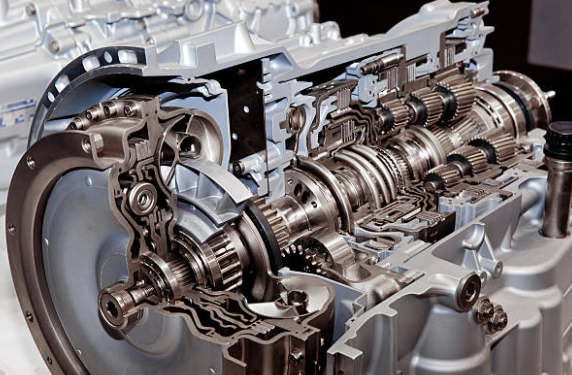

To comprehend the dynamics of energy management in EVS, it’s essential to grasp the fundamentals of a car’s braking system. The goal of the braking system is to dissipate the vehicle’s energy. It does this by using friction between brake pads and rotors to slow down and eventually stop the vehicle.

Currently, most vehicles use a traditional hydraulic system. However it is becoming more and more common for automakers to incorporate newer higher tech brake-by-wire systems into their vehicles. With the rise of electrified vehicles, an even more sophisticated approach is taken to maximize efficiency and minimize energy wastage.

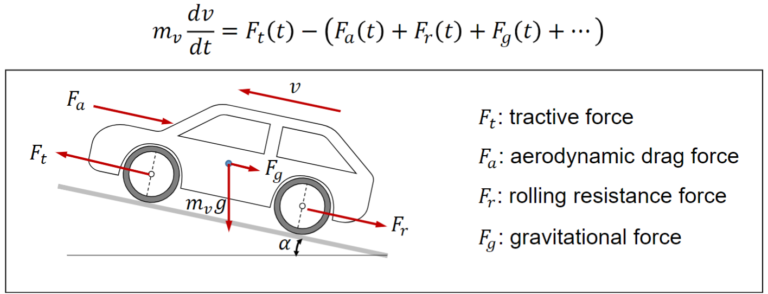

Vehicle Braking System Physics: A Balancing Act

When a driver applies the brakes in a conventional car, the vehicle’s kinetic energy is converted into heat energy. This is done through the friction between the braking components. In contrast, electrified vehicles provide an opportunity to harness this energy. It does this by using a combination of regenerative and friction braking. This allows EVs to achieve a delicate balance between slowing down the vehicle and recouping energy.

Vehicle Braking System Forces

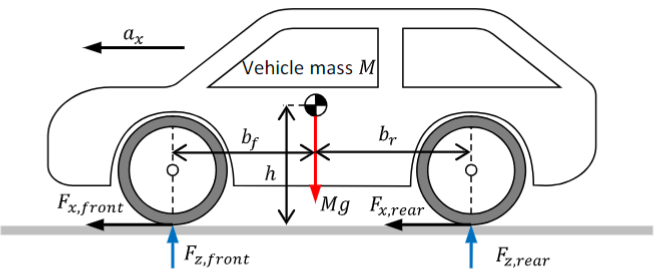

To achieve this, engineers carefully calibrate the braking forces, considering factors such as vehicle mass, speed, and the desired rate of deceleration. Understanding braking forces is essential for designing effective braking systems that can safely stop a vehicle in various conditions. The braking forces can be divided into two groups: longitudinal braking and vertical braking force.

• Longitudinal forces

𝐹𝑥,𝑓 = 𝑀𝑎𝑥𝛾, 𝐹𝑥,𝑟 = 𝑀𝑎𝑥 (1 − 𝛾)

• Vertical forces

𝐹𝑧,𝑓 = 𝑏𝑟/𝐿 (𝑀𝑔) − ℎ/𝐿 𝑀𝑎𝑥, 𝐹𝑧,𝑟 = 𝑏𝑓/𝐿 (𝑀𝑔) + ℎ/𝐿 (𝑀𝑎𝑥 )

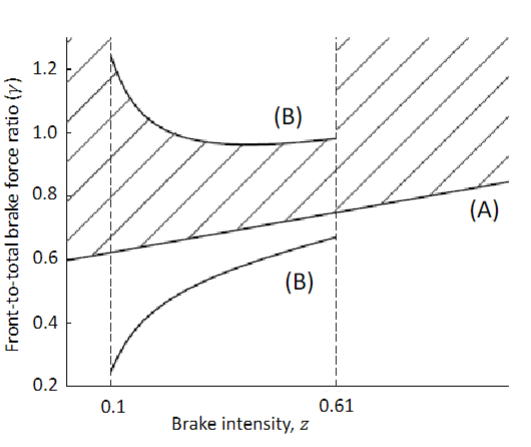

Despite the advancements in braking technology, there are inherent challenges in managing the forces involved. Braking constraints are crucial in maintaining stability and control during braking. If the rear wheels lock up while braking, the vehicle can become unstable, leading to oversteer. To prevent this, Regulation 13 of the United Nations Economic Commission for Europe (UNECE) outlines conditions to avoid such situations. One important constraint specified by this regulation is the ratio of the front axle braking force to the total braking force, represented by the symbol 𝛾. This constraint helps ensure that braking forces are distributed properly between the front and rear axles. Thus optimizing stability and preventing instability during braking. Where 𝐹𝑥,𝑡𝑜𝑡 is the total braking force demand.

𝛾 = 𝐹𝑥,𝑓 / 𝐹𝑥,𝑡𝑜𝑡

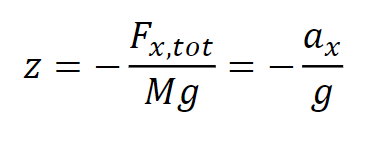

What is Braking intensity

Braking intensity (Z), which is the ratio of the total braking force demand to gravitational force acting on the vehicle (Mass *gravity). see the equation below:

Adhesion utilization

Adhesion utilization, denoted as 𝑘, is another key factor, representing the ratio of the braking force to the maximum braking force at a given axle. According to Regulation 13 of the United Nations Economic Commission for Europe (UNECE), requirements 3.1.1 and 3.1.2 stipulate specific constraints to be met. These include the condition 𝑘𝑓 ≥ 𝑘𝑟 (A), ensuring that the front axle’s braking intensity is greater than or equal to the rear axle’s braking intensity. Additionally, it condition (B) specifies that the ratio 𝑘 must be within the range of 0.85k < 𝑧 + 0.07 for 𝑧 values ranging from 0.1 to 0.61, further optimizing braking efficiency and safety.

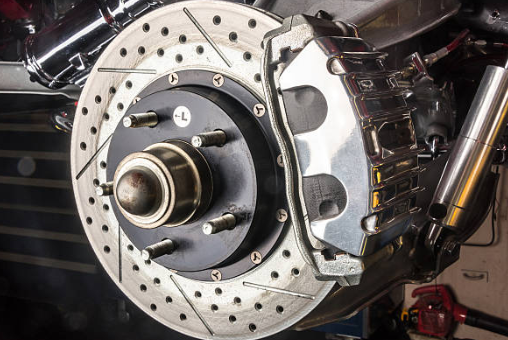

EV Issues With Traditional Braking System

During normal braking in any vehicle, moisture naturally accumulates on brake pads. In internal combustion engine (ICE) vehicles, the braking system is the primary means of slowing down, leading to frequent use of the brakes. This usage generates heat from the friction between the brake pad and the brake disc or drum, causing any accumulated moisture to evaporate and prevent corrosion of the pads.

However, electric vehicles (EVs) use the brakes much less frequently. As a result this means that any moisture buildup may not evaporate as quickly. Without corrosion-resistant brake pads, rust can accumulate, leading to deterioration of the pad backing and breakdown of the adhesive used to attach the backing to the friction material. Ironically, this can result in traditional brake pads wearing out faster on EVs than on ICE vehicles.

Regenerative Braking: Harnessing the Power of Deceleration

At the heart of efficient energy management in electrified vehicles lies the concept of regenerative braking. Regenerative braking employs electric motors instead of traditional friction braking systems to decelerate and stop a vehicle. In a conventional hydraulic braking system, typically utilizing disc brakes or drum brakes, braking results in energy wastage. A traditional braking system converts the kinetic energy propelling the car forward into heat. While effective at slowing down the vehicle, the heat generated from braking friction is no longer able to be harnessed or utilized.

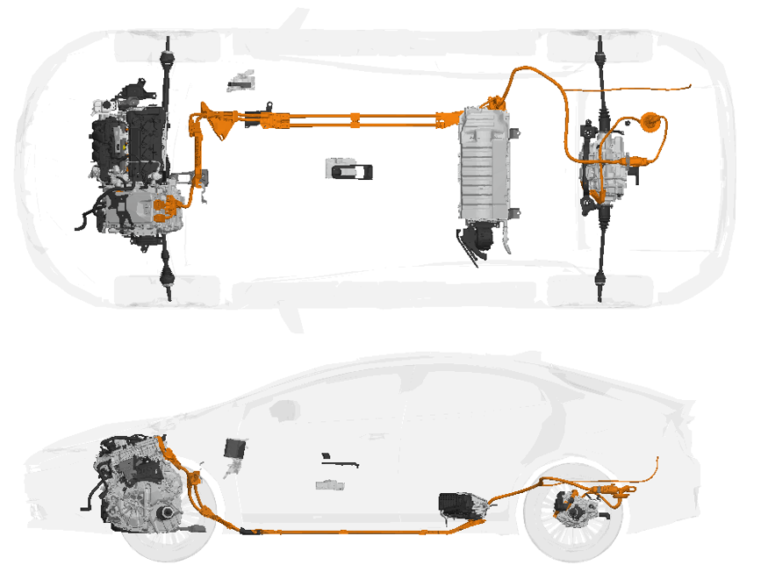

Regenerative brakes capture the kinetic energy during braking and transfer it to the car’s batteries, minimizing energy wastage compared to friction braking. It’s estimated that in most hybrids, up to 90 percent of the energy normally lost as heat during braking is captured and used to recharge the battery through electrical motor resistance, thereby assisting in preserving and replenishing the range of an electric or plug-in hybrid vehicle.

In a conventional hybrid, the energy recovered from regenerative braking helps power various auxiliary functions in the car, such as the audio and climate control systems. This reduces the load on the engine and electrical system, enhancing overall efficiency.

How Does a Regenerative Braking System Work

Regenerative brakes work by reversing the electric motors that propel a vehicle, functioning as a generator. This process feeds energy back into the hybrid or electric system, assisting in replenishing a portion of the vehicle’s range. These incremental boosts in battery range can accumulate and enhance efficiency over time with regular use.

Regenerative braking systems intelligently switch between regenerative and friction braking based on driving conditions. During light braking or coasting, the vehicle primarily relies on regenerative braking to maximize energy recovery. However, in more aggressive braking scenarios, such as sudden stops or emergencies, friction brakes are engaged to provide the necessary deceleration.

While regenerative brakes operate differently from friction brakes, they serve the same purpose of slowing down and halting a moving vehicle. Because regenerative brakes produce a similar effect to conventional brakes, the brake lights are still activated when using regenerative braking as a safety measure. This means that when you release the accelerator, the regenerative brakes engage automatically, causing the brake lights at the rear of the car to illuminate, just as they would if you were to press the brake pedal.

Energy Demand – Recuperation: A Symbiotic Relationship

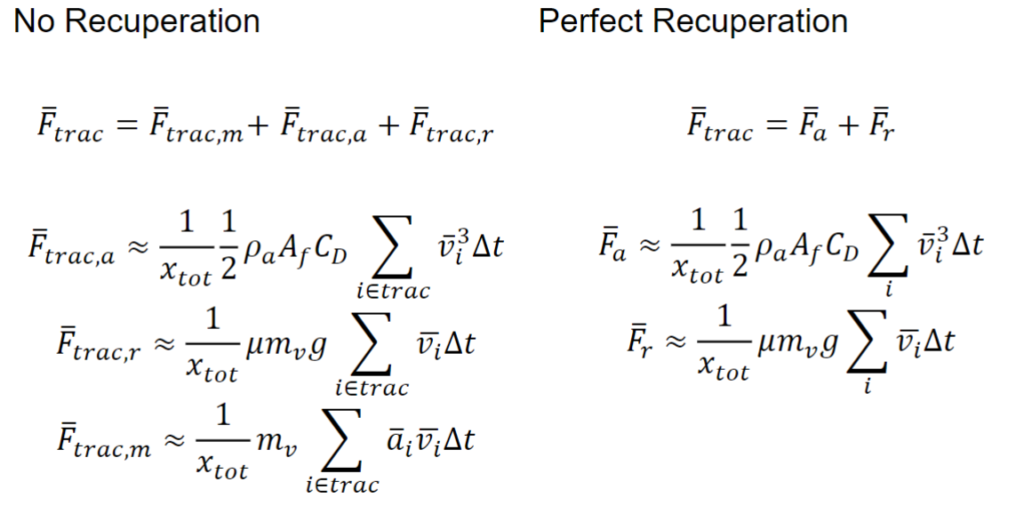

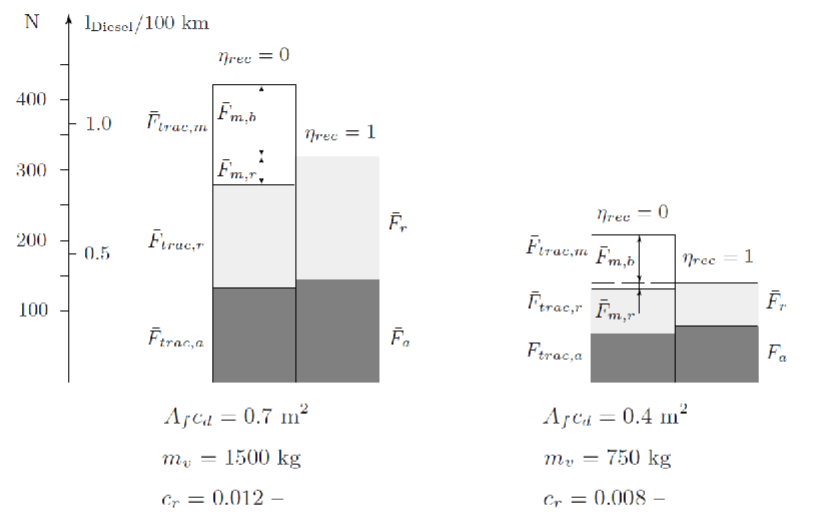

Remembering the vehicle dynamics equations we know that the aerodynamic and the rolling-resistance forces are always dissipative, i.e., 𝐹𝑎,𝑖 + 𝐹𝑟,𝑖 ≥ 0. If a vehicle is equipped with an energy recuperation device, some of the vehicle’s kinetic energy can be recovered during driving.

The success of energy management in electrified vehicles hinges on the harmonious interplay between energy demand and recuperation. A well-designed system anticipates the driver’s energy requirements and adjusts the braking strategy accordingly. Advanced algorithms analyze various parameters that can impact driving cycles, including driving habits, terrain, and traffic conditions, to optimize the balance between energy consumption and recuperation.

Even in the case with no additional recuperation device, the vehicle utilizes some of its kinetic energy to drive parts of the cycle. 𝐹𝑚,𝑏 is later dissipated as heat by the brakes.

Conclusion

In conclusion, the energy management of electrified vehicles, especially braking systems, represents a captivating synergy of engineering precision and environmental consciousness. As we witness the continued evolution of electric mobility, understanding these intricate systems becomes not just a technical curiosity but a key to unlocking the full potential of sustainable transportation. The roads ahead are paved with innovations, and the efficient management of braking energy is steering us toward a future where every deceleration is an opportunity for progress.