SAE J1100 – Motor Vehicle Dimensions

The following is a summary of SAE J1100.

Scope

This SAE Recommended Practice defines standardized measurements and procedures for vehicle dimensions, focusing primarily on design intent within a CAD environment, although some measurements can also be taken on physical vehicles. Variations may occur between design and actual measurements, and care should be taken not to confuse the two. The guidelines apply to both the HPM (SAE J826) and HPM-II (SAE J4002), with dimensions typically measured relative to a three-dimensional reference system or ground, depending on the type.

The base vehicle measurements exclude optional or accessory parts unless specified. The latest revision mostly includes editorial updates for clarity, with modified and added dimension definitions, as well as updates to leg room, knee clearance, and vehicle angle measurements.

References

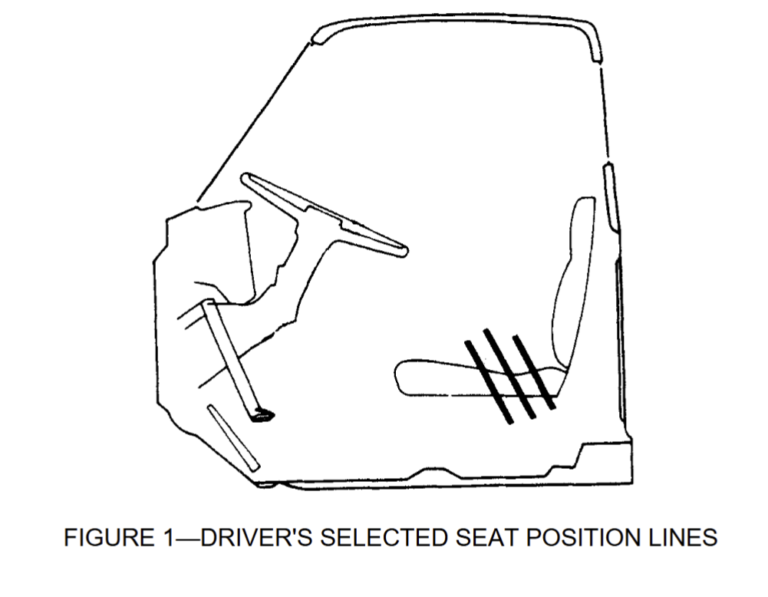

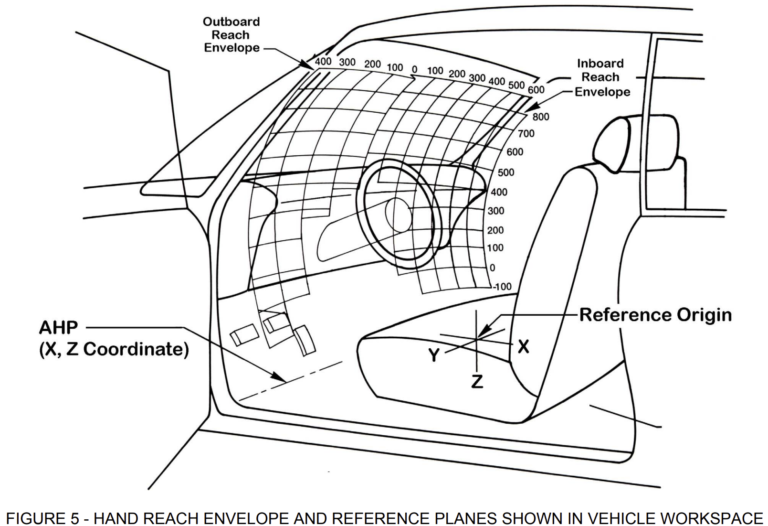

This section lists relevant publications that are part of the specification. For SAE standards, the latest versions apply and include guidelines for vehicle fiducial marks, driver reach, seating accommodation, driver eye range, head positioning, seat position, and H-Point Machine procedures. ISO publications referenced include methods for measuring vehicle luggage compartment volume and terminology for vehicle masses and types, though these ISO standards are informational and not mandatory for this specification.

SAE Publications:

- SAE J182 — Motor Vehicle Fiducial Marks

- SAE J287 — Driver Hand Control Reach

- SAE J826 — Devices for Use in Defining and Measuring Vehicle Seating Accommodation

- SAE J941 — Motor Vehicle Driver’s Eye Range

- SAE J1052 — Motor Vehicle Driver and Passenger Head Position

- SAE J1516 — Accommodation Tool Reference Point

- SAE J1517 — Driver Selected Seat Position

- SAE J2732 — Automotive Seat Dimensions (Pending)

- SAE J4002 — H-Point Machine (HPM-II) Specifications and Procedure for H-Point Determination Auditing Vehicle Seats

- SAE J4003 — H-Point Machine (HPM-II) Procedure for H-Point Determination—Benchmarking Vehicle Seats

- SAE J4004 — Positioning the H-Point Design Tool—Seating Reference Point and Seat Track Length

ISO Publication:

- ISO 3832 — Passenger cars—Luggage compartments—Method of measuring reference volume

Related ISO Publications (for reference only):

- ISO 4131 — Road vehicles—Dimensional codes for passenger cars

- ISO 1176 — Road vehicles—Masses—Vocabulary and codes

- ISO 3833 — Road vehicles—Types—Terms and definitions

Definitions

Section 3.1 categorizes motor vehicles as follows:

- Passenger Car: Designed to carry up to 10 people, excluding multipurpose vehicles, motorcycles, and trailers. Includes:

- Station Wagon: Extended upper section for more cargo or passenger space.

- Hatchback: Rear door includes the rear window.

- Light Truck: Primarily for cargo transport, with a GVWR of 4,536 kg (10,000 lb) or less. Includes:

- Multipurpose Passenger Vehicle (MPV): Light trucks with a cargo area open to the passenger compartment, often built on a truck chassis and suitable for occasional off-road use (e.g., SUVs, vans, crossovers).

- Heavy Truck: Designed mainly for cargo transport with a GVWR over 4,536 kg (10,000 lb).

Additional classifications in Tables 1 and 2 use five dimensions to determine suitable procedures for SAE standards like SAE J287 and J941.

Table 1 for Class A Vehicles:

| Dimension | Code | Range |

|---|---|---|

| Chair Height | H30-1 | 127 to 405 mm |

| Design H-point Rise | TH17 | 0.0 to 50 mm |

| Normal Driving and Riding Seat Track Travel | TL23 | 100 mm or more |

| Steering Wheel Diameter | W9 | less than 450 mm |

| Back Angle | A40-1 | 5 to 40 degrees |

Table 2 for Class B Vehicles:

| Dimension | Code | Range |

|---|---|---|

| Chair Height | H30-1 | 405 to 530 mm |

| Design H-point Rise | TH17 | 0 mm |

| Normal Driving and Riding Seat Track Travel | TL23 | 100 mm or more |

| Steering Wheel Diameter | W9 | 450 to 560 mm |

| Back Angle | A40-1 | 11 to 18 degrees |

The document defines various vehicle weight and load terms, starting with “curb weight,” which represents the weight of a base vehicle with all fluids filled to their maximum levels. However, for heavy trucks, this excludes engine fuel. “Gross Vehicle Weight Rating” (GVWR) is the manufacturer-specified maximum loaded weight for a single vehicle. Coordinate dimensions are described as points in a 3D reference system (X, Y, Z) measured from zero planes, with references made to SAE J182 for standardization.

Vehicle fiducial marks refer to specific reference points on the vehicle, as per SAE J182. The “cargo floor” supports cargo, where the surface is considered at the top of any ribs or, if covered, the undepressed covering surface. The “centerline of occupant” (C/LO) indicates the lateral centerline of an occupant’s designated seating. The “cowl point” is the vehicle’s centerline, marking the highest point on the cowl or hood, and “daylight opening” (DLO) describes the minimum unobstructed opening through any glass aperture, considering elements like opaque coatings or moldings as obstructions. The “deck point” marks the highest point on the deck lid panel at the vehicle centerline, while “depressed floor covering” refers to the floor’s surface under load at a specific point in the vehicle.

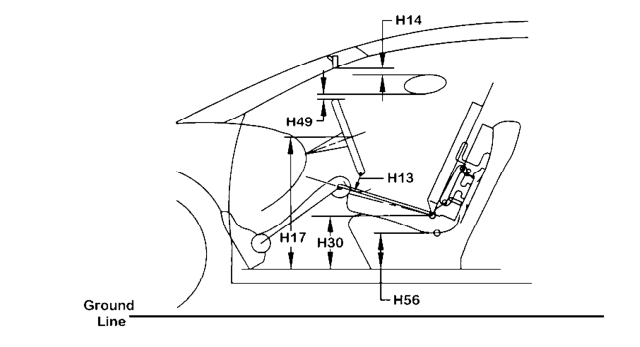

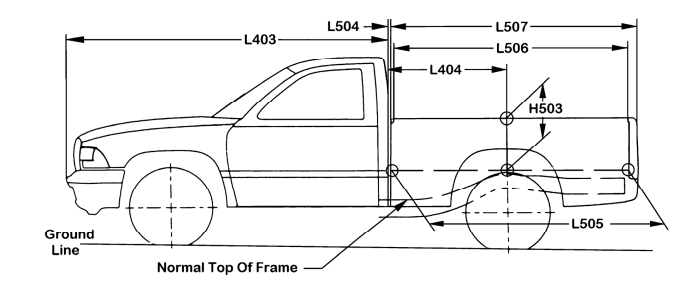

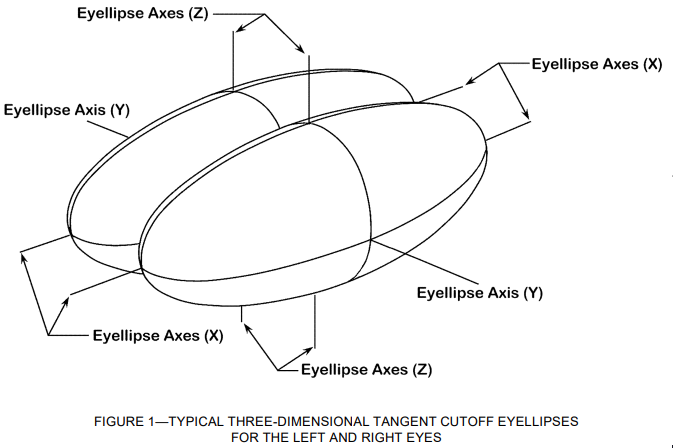

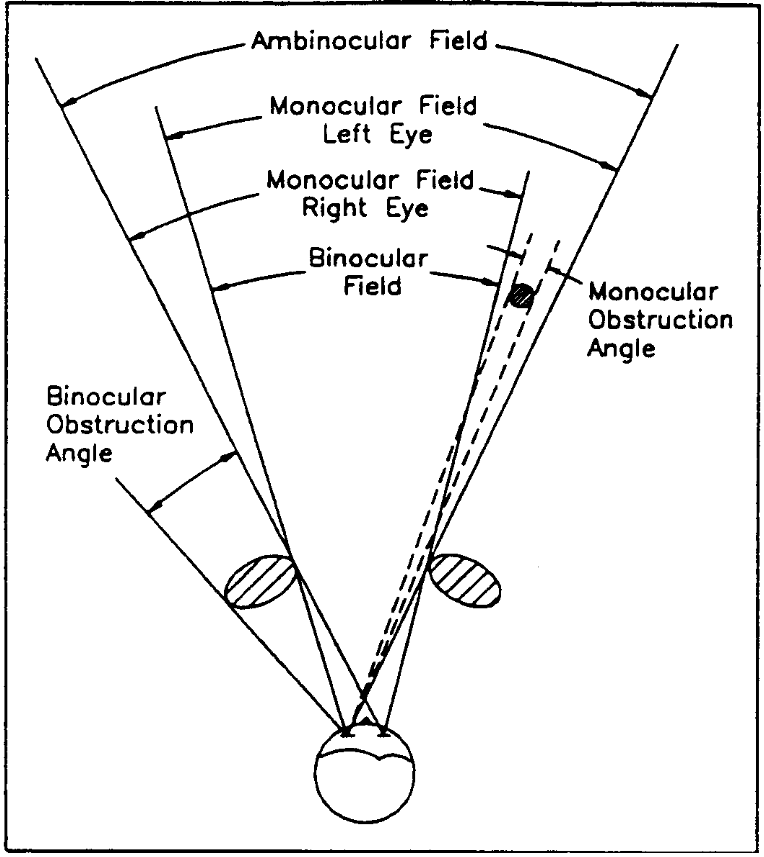

A “designated seating position” includes any intended location for driver or passenger seating while the vehicle is in motion, excluding temporary jump seats. Measurements target one designated seating position per row for consistency. The “eyellipse” concept, defined in SAE J941, aids in ergonomic considerations, while the “front of dash” is a vertical line on the foremost part of the dashboard for vehicle design alignment. “Head position contour,” based on SAE J1052, provides dimensional specifications for seating adjustments using sections through a 95th percentile head contour. “Normal top of frame” in trucks indicates the longest flat portion of the top flange within the wheelbase. The “undepressed floor covering” is the floor surface without any applied load, relevant for unweighted measurements.

“Long-coupled seating” is where row seating allows for a larger ankle angle (>130 degrees) for H-point device placement, while “short-coupled seating” results in device interference when moving between rows, impacting dimensions like leg and knee clearance. The “belt line” represents the lower edge of the DLO. In cases without a glass aperture, the belt line connects adjacent openings’ lower edges. “Maximum hold-open position” is the furthest point a vehicle closure can maintain without external force or device removal.

H-point devices establish interior reference points, primarily the H-point itself, via physical tools (HPM, HPM-II) or CAD (HPD), helping with design and benchmarking. The document references SAE standards (J826, J4002, J4003, J4004) for usage. Specific terms include “back line,” determining back angle from the H-point to thorax pivot, “cushion line” setting cushion angle on the HPM, and “D-point,” the cushion pan’s low point rearward of the H-point. The H-point itself signifies a pivotal design reference within a vehicle, representing the intersection of back and cushion lines for a specific seating position.

An “H-point travel path” encompasses the range of possible H-point locations based on adjustable seats, excluding positions aiding entry or cargo storage. The “K-point,” or knee pivot point, marks the pivot between thigh and lower leg segments. “Lower leg line” connects the K-point and ankle pivot center on the H-point devices, useful for measuring ergonomic leg angles. The “Seating Reference Point” (SgRP) uniquely identifies the H-point for each designated seating position, particularly for the driver. SgRP influences key interior dimensions like legroom and shoulder room and follows specific SAE standards for determination.

Code Explanation, Vehicle Set-Up, and Dimensioning Procedure

Each dimension is designated by a code made up of an alphabetical prefix followed by a number (for instance, H30 or A40). The letters indicate the direction of the measurement (such as height or width) or the type of measurement (such as angle). Refer to Tables 3 and 4 for further details.

TABLE 3—ALPHA PREFIXES

| Letter | Meaning |

|---|---|

| W | Width measurements (cross-car distance), or location of Y coordinate |

| L | Length measurements (longitudinal distance), or location of X coordinate |

| H | Height measurements or location of Z coordinate |

| A | Angular measurements |

| PW | Widths associated with pedal and pedal usage |

| PL | Lengths associated with pedal and pedal usage |

| PH | Heights associated with pedal and pedal usage |

| TL | Lengths defining H-point locations/travel |

| TH | Heights defining H-point locations/travel |

| PD | Passenger distribution |

| S | Surface area measurements |

| SW | Widths associated with seats |

| SL | Lengths associated with seats |

| SH | Heights associated with seats |

| V | Volume indices |

TABLE 4—NUMERIC SCHEME (GENERAL)

| Number Range | Type of Dimension |

|---|---|

| 1-99 | Interior |

| 100-199 | Exterior |

| 200-299 | Cargo compartments |

| 400-599 | Dimensions unique to trucks, vans, sport utility vehicles, etc. |

Interior dimension codes

Interior dimension codes can be applied to multiple seating positions, where the base alphanumeric code remains unchanged but is supplemented with a suffix (e.g., H30-1, H30-2) to indicate the specific seating row. In equations, the hyphen (-) in these codes is replaced with a tilde (~).

Exterior dimension codes

Exterior dimension codes are similarly used for measurements across the front and rear halves of the vehicle. Each basic alphanumeric code has a suffix added to denote the specific condition related to the measurement (e.g., L102-1 for the front overhang and L102-2 for the rear). As with interior codes, the hyphen (-) is replaced with a tilde (~) in equations.

TABLE 5—SUFFIXES

| Suffix | Designated Seating Position |

|---|---|

| -1 | Measurement taken at the driver’s designated seating position. |

| -2 | Measurement taken at the second row outboard passenger’s designated seating position. |

| -3 | Measurement taken at the third row outboard passenger’s designated seating position. |

| -4 | Measurement taken at the fourth row outboard passenger’s designated seating position. |

| -5 | Measurement taken at the fifth row outboard passenger’s designated seating position. |

Exterior

| Suffix | Forward/Rearward Position |

|---|---|

| -1 | Measurement taken in the front portion of the vehicle. |

| -2 | Measurement taken in the rear portion of the vehicle. |

Interior Dimensions:

Measurements are taken with the seats positioned according to Table 6, at the Seating Reference Point (SgRP) location. Any adjustable features, such as lumbar support, must be set to the retracted or least intrusive position. Other adjustable components, including the steering wheel and seat height, should be positioned as directed by the manufacturer. Measurements are taken from the occupant’s centerline, and when using an H-point device, the 95th percentile leg segment lengths (J826) or SgRP leg lengths (J4002) are applied.

Exterior Dimensions:

Exterior dimensions end at the outer surface of the vehicle’s sheet metal, bumpers, or moldings unless noted otherwise. The front wheels must be aligned straight ahead, and measurements are to be recorded at curb load on a base-equipped vehicle. For vehicles with dual rear axles, measurements are taken to a midpoint between the rear wheels. Codes and definitions for these exterior dimensions can be found in Tables 21 through 24.

Dimensions for Key Coordinates

All coordinates are defined in relation to the vehicle grid as specified in SAE J182. The Seating Reference Point (SgRP) coordinates can be referenced in Section 3.6.7 and Table 8. The Accelerator Heel Point (AHP) coordinates apply solely to the driver’s position, with definitions found in Table 9. Similarly, the Pedal Reference Point (PRP) coordinates are specific to the driver’s position, detailed in Table 10, along with additional information in Section 3.7.9 and SAE practices J4002, J4003, J4004, and J826. The Floor Reference Point (FRP) coordinates are defined in Table 11, with further details in Section 3.7.6 and the same SAE practices. Lastly, for definitions of additional coordinates used in this practice, refer to Table 12 and Section 3.7.1, along with SAE practices J4002, J4003, J4004, and J826.

Cargo Dimensions and Cargo Volume Indices

Cargo dimensions and volume indices offer estimates of cargo compartment sizes to aid in vehicle design and engineering. However, discrete measurements of irregular spaces, such as those within a vehicle’s interior, can be ambiguous and may yield varying results due to minor local variations. Tables 25 to 27 provide the codes and definitions for cargo dimensions, while Table 28 outlines the codes and formulas for calculating cargo volume indices (CVI). For cargo length measurements, the area from the cargo surface to the rear of the forward measurement point must be unobstructed, and seats must be stowed or optimized for cargo; if an obstruction exists, measurements are taken from the most rearward surface of the obstruction.

The cargo volume indices are intended to give reasonable estimates of stowage potential rather than actual cargo volumes. They are calculated using the formula:

(Length x Width x Height) / 106 = Liters

with dimensions measured (L x W x H) in millimeters. To avoid confusion, the suffix denoting the measurement row is separated from the code by a tilde (~). For calculating CVIs in English units, the formula is adjusted accordingly, with specific conversions provided for metric measurements.

(Length [inches] x Width [inches] x Height [inches]) / 1728 = Cubic FT

Luggage Capacity Dimensions

The luggage set is detailed in Table 29, while luggage capacity, outlined in Table 30, is measured with all standard vehicle equipment—such as spare tires, convertible tops, and tool kits—in their designated storage locations. To assess luggage capacity, pieces labeled A through G from the luggage set are placed randomly in the compartment, with H-boxes used to fill any remaining space. If necessary, one or more standard luggage pieces can be removed to accommodate H-boxes, as long as those pieces can be replaced. For larger compartments, an entire set of luggage must be utilized before adding pieces from another set. Additionally, if space permits, more than the standard 20 H-boxes can be used. Finally, the trunk lid or access door must close and latch properly after fitting in the luggage.

It’s laborious to find educated individuals on this topic, but you sound like you realize what you’re talking about! Thanks