The Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine. There are two commonly used reciprocating heat engines found on the market today. The spark ignition (SI) engines and compression ignition (CI) engines. Due to their different ignition mechanisms, these engines have varying fuel property requirements. For instance, SI engines need volatile fuel with excellent anti-knocking properties, while CI engines require fuel with good ignition ability and low viscosity. Among the renewable fuels available for SI engines, ethanol is considered significant globally due to its large-scale production, higher combustion efficiency, and lower emissions.

Currently, the ICE remains central to the modern transportation sector. Around 95% of ICEs still rely on traditional fossil fuels due to their high energy density and ease of transport and storage. However, fossil fuels are non-renewable, and their combustion releases pollutants that can cause environmental contamination and contribute to global warming.

The ICE fuel burns with an oxidizer (usually air) inside a combustion chamber. When the fuel burns, it creates high-temperature, high-pressure gases that apply direct force to parts of the engine. This force typically acts on pistons (in piston engines), turbine blades (in gas turbines), a rotor (in Wankel engines), or a nozzle (in jet engines). This action moves these components, converting chemical energy into kinetic energy to propel, move, or power whatever the engine is connected to.

History of an Internal Combustion Engine

The first commercially successful internal combustion engine was invented by Étienne Lenoir around 1860. The first modern internal combustion engine, known as the Otto engine, was created by a German engineer, Nicolaus Otto in 1876. “internal combustion engine” typically refers to engines where combustion occurs intermittently. The diesel engine was invented by a German mechanical engineer and inventor in 1897. Rudolf Diesel. Some common ICE are the two-stroke and four-stroke piston engines. As well as variants such as the six-stroke piston engine and the Wankel rotary engine.

What are the 4 types of internal combustion engines?

Internal combustion engines are the most commonly used power-generating devices today. Examples include:

- Gasoline engines found in most passenger cars/ trucks

- Diesel engines are found in most heavy machinery and semi-truck/ 18-wheeler

- Gas turbine engines found in most aircraft and powerplants

- Rocket propulsion systems found in space crafts

Why are diesel engines called CI engines?

Diesel engines are often called compression-ignition engines because combustion is initiated by air heated through compression instead of an electric spark. In a diesel engine, fuel is injected as the piston nears the top dead center of its compression stroke.

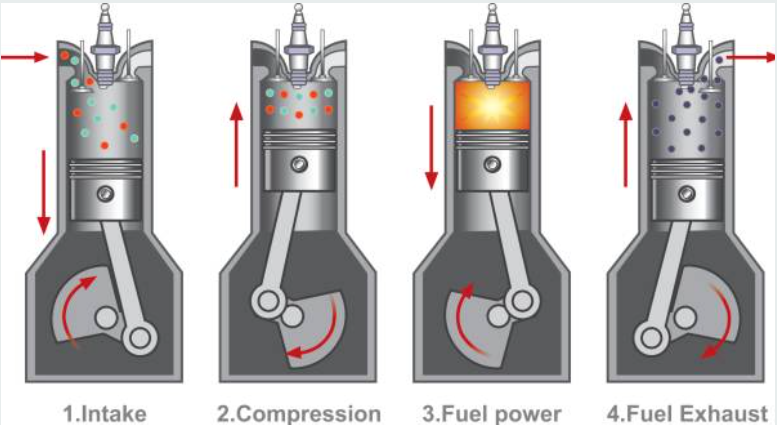

What is the working principle of the Internal Combustion Engine?

A piston engine is a type of machine that generates pressure through fuel combustion. Once the air and fuel mixture is ignited the air expands within a cylinder, pushing the piston to move and perform work. Think of this as a mini explosion inside of your engine.

The expanding combustion gases push the piston, which then rotates the crankshaft. This movement is transferred through gears (transmission, drive shaft, transfer case, etc.) in the powertrain to drive the vehicle’s wheels.

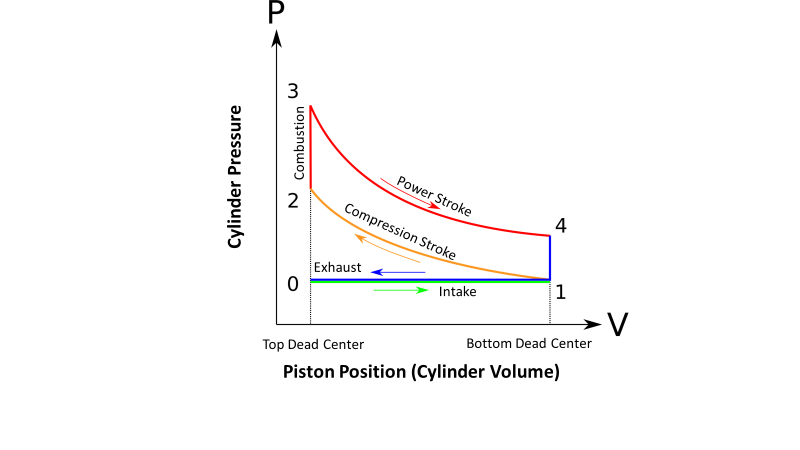

What is the thermodynamic cycle of a piston engine called?

The Otto cycle is an idealized thermodynamic cycle that explains how a typical spark ignition piston engine operates. This cycle is most commonly found in automobile engines.

Do cars have an Internal Combustion Engine?

A gasoline car usually operates with a spark-ignited internal combustion engine, unlike the compression-ignited systems found in diesel vehicles. In a spark-ignited system, fuel is injected into the combustion chamber and mixed with air. A spark from the spark plug then ignites this air-fuel mixture.

What is the most common type of internal combustion engine?

The four-stroke cycle engine is the most common type of automotive engine. It completes five strokes in one operating cycle: intake, compression, ignition, power, and exhaust. Two-stroke engines can be found on smaller lawn equipment such as weed wackers and leaf blowers.

How do I know if my motor is 2-stroke or 4-stroke?

The simplest way to differentiate between a 2-cycle engine and a 4-cycle engine is by checking the number of fill ports for the fuel tank and oil sump. A 2-cycle engine has a single fill port with a cap displaying both a fuel pump and an oil can icon. This cap typically indicates the oil-to-fuel mix ratio.

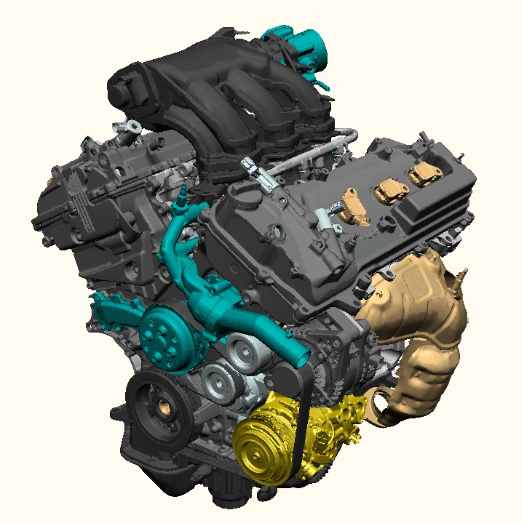

What is an engine system?

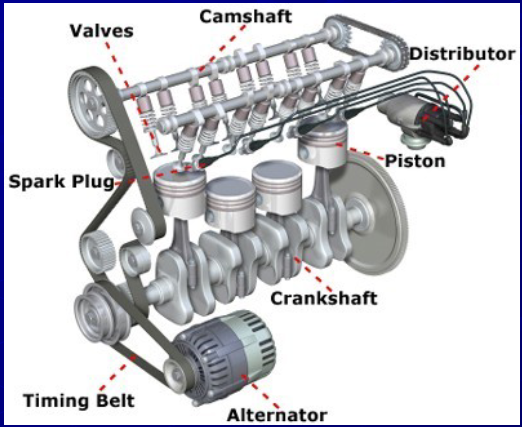

Engine systems encompass a variety of components that ensure the proper functioning of the engine.

- Engine structure forms the foundation, providing support and housing for the internal components.

- Power conversion mechanisms, such as the pistons and crankshaft, convert the energy generated by the combustion process into rotational motion.

- valve train regulates the intake of air and fuel and the expulsion of exhaust gases.

- Engine lubrication ensures that all moving parts are properly lubricated to reduce friction and wear.

- Engine cooling systems prevent overheating by dissipating excess heat.

- The fuel system delivers the correct amount of fuel to the engine for combustion.

- The air intake system ensures the proper air-fuel ratio.

- Ignition systems ignite the air-fuel mixture at the right time for combustion.

- Timing systems ensure that the valves open and close at the correct times.

Finally, major sealing components, such as gaskets and seals, prevent leaks and maintain proper compression within the engine. Various accessories, such as the alternator and power steering pump, are driven by the engine to provide additional functionalities.

What is the main structure of an engine?

The cylinder block is the most crucial component and serves as the foundation of a car engine. The component engine block is usually cast out of iron or aluminum. Its main function is to house the crankshaft mechanism. Inside the cylinder block are several engine cylinders, each connected to a piston and linked to the crankshaft at the other end.

The engine structure consists of several components, including the cylinder block, which houses the engine’s cylinders. It contains liner sleeves, bearing caps, and plugs. The cylinder block accessories include knock sensors, oil sensors, and lifting eyes. Additionally, there is also a crankshaft position sensor mounted to the block. These components work together to form the foundation of the engine, supporting its operation and performance.

Engine Power Conversion System

The power conversion components of an engine include rotating components like the crankshaft, upper bearings, lower bearings, and a trigger wheel. The piston and rod assembly consists of pistons, pins, connecting rods, caps, upper bearings, lower bearings, oil/ compression rings, and bolts. These components work together to convert the energy generated by the combustion process into rotational motion, which drives the vehicle’s transmission and ultimately propels the vehicle forward.

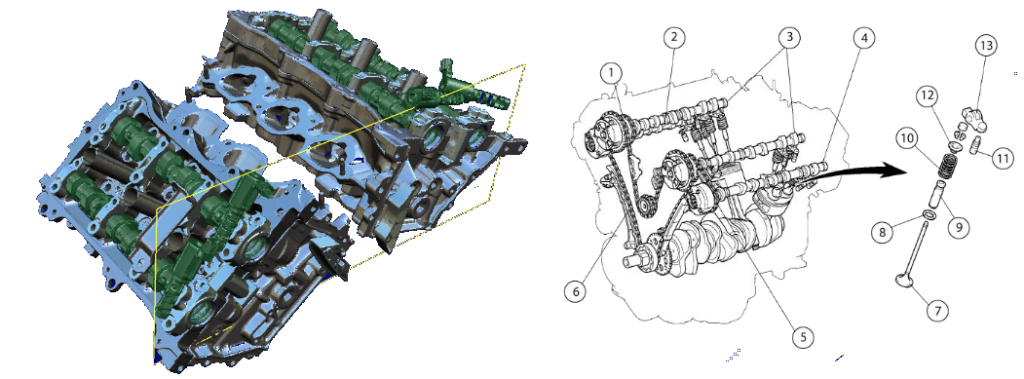

What is an engine valve train?

The valvetrain comprises all components tasked with converting the rotational motion of the camshaft into the opening and closing actions of the intake and exhaust valves. These components typically include those listed below, arranged in order from the crankshaft to the valves.

The valve train of an engine consists of various components, including cylinder heads, fasteners to attach them to the block, cylinder head gaskets, spark plug tubes, valve seals, plugs, camshaft carriers, caps, fasteners for the caps, variable camshaft solenoids, and fasteners to attach them to the cylinder head. Additionally, there are kinetic camshafts, valves, retainers, keys, and plugs. These components work together to control the opening and closing of the engine’s valves, ensuring proper timing and function for efficient engine operation.

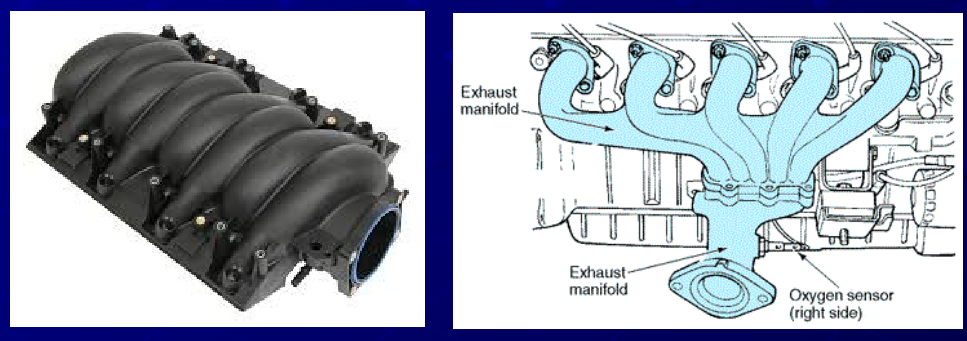

What is the function of the intake exhaust system?

The air intake system collaborates with the exhaust system to regulate the entry of fresh air into the engine and the exit of used gases. These systems are engineered for simplicity and longevity. The inlet manifold directs air into the engine, while the exhaust manifold expels combustion gases. Air filters require regular cleaning, ensuring that the air entering the engine closely matches the ambient temperature and is free of debris. The valve train controls the flow of air and exhaust throughout the engine.

The engine’s air intake and exhaust system is a critical subsystem comprising several components. Components of this system include the inlet hose, air filter, inlet valve, exhaust valve, exhaust hose, muffler, catalytic converter, camshafts, rocker arm, tappets, chain drive, sprockets, push rod, return spring, and either a hydraulic or mechanical actuator. These components work together to ensure the proper flow of air and exhaust gases, contributing to the engine’s performance and efficiency.

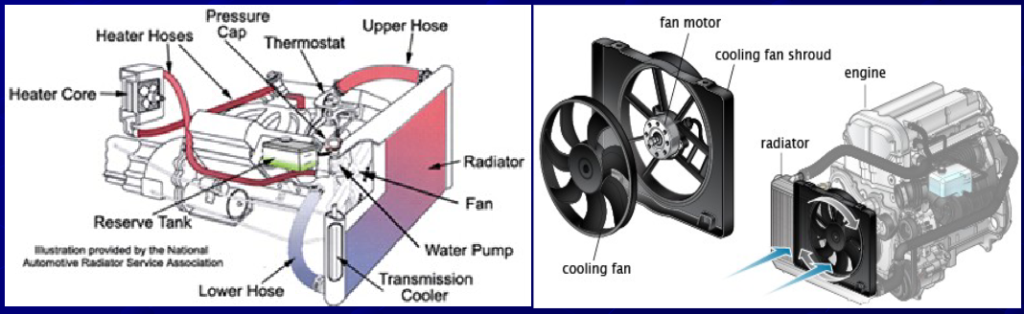

What is the main engine cooling system?

The engine cooling system is a vital subsystem that helps maintain the engine’s operating temperature within a safe range. The cooling system operates by circulating coolant through channels within the engine block. Driven by a water pump, the coolant flows through the cylinder block, absorbing heat from the engine as it passes through these channels.

It consists of several components, including the radiator heat exchanger, coolant fluid, hoses, pump, thermostat, non-return valve, cooling fan, and fan motor. The radiator system efficiently dissipates heat from the coolant fluid, which is circulated through the engine to absorb excess heat. The radiator fan system helps regulate airflow through the radiator, enhancing the cooling process via convection with outside air. Together, these components ensure that the engine operates at an optimal temperature, preventing overheating and maintaining efficient performance.

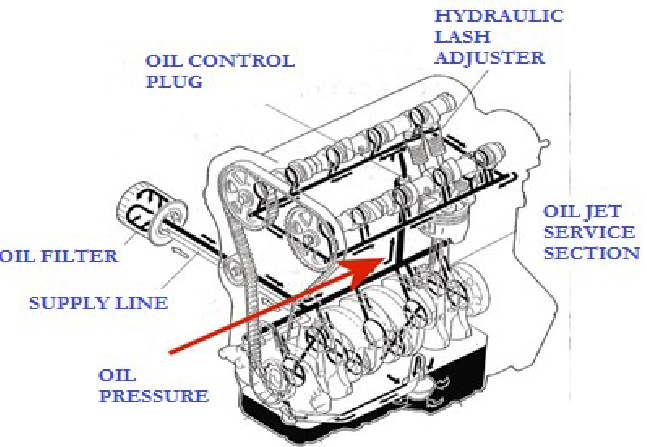

What is an engine lubrication system?

The engine lubrication system is a critical subsystem that ensures the engine’s moving parts are properly lubricated to reduce friction and wear. Effective lubrication significantly impacts the longevity of an automotive engine by reducing friction between surfaces.

It comprises several components, including the strainer, oil pump, supply line, oil filter, and supply lines. The pressurized system ensures that oil is delivered to the engine’s components under pressure, while the supply system ensures a continuous flow of oil. The drain system is responsible for collecting and returning oil to the reservoir for recirculation. Together, these components work to maintain the engine’s lubrication, ensuring smooth operation and prolonging the engine’s lifespan.

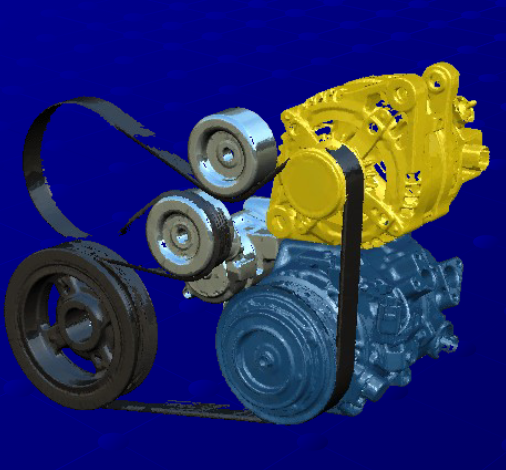

What are the accessories on an Internal Combustion Engine?

Typical engine accessories include various components that are essential for the engine’s operation and performance. These accessories include drive components such as the drive pulley, starters, pumps, sensors, valves, serpentine belts, tensioners, and idler pulleys. The drive pulley is responsible for transferring power from the engine to other accessories. The serpentine belt connects the drive pulley to the accessories, while the tensioner maintains proper belt tension.

The idler pulley helps guide the belt. In terms of electrical components, there is typically an alternator that generates electricity to charge the battery and power the vehicle’s electrical systems. Additionally, there are cables and wire harnesses to connect the electrical components. For air conditioning, there is an AC compressor that pressurizes the refrigerant, along with AC tubes to circulate the refrigerant. All these components work together to ensure the engine runs smoothly and efficiently.

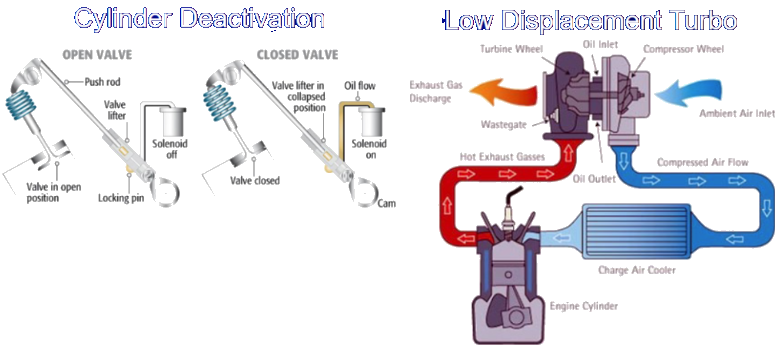

Engine Technologies

Engine technologies such as low displacement turbo and cylinder deactivation are revolutionizing the automotive industry. Low displacement turbo technology involves using a smaller engine size with a turbocharger to achieve the power output of a larger engine while improving fuel efficiency. This technology allows for better performance without compromising on fuel economy.

On the other hand, cylinder deactivation technology enables an engine to deactivate specific cylinders when full power is not required, such as during cruising. This reduces fuel consumption and emissions while maintaining engine performance. Both technologies contribute to more efficient and environmentally friendly vehicles, aligning with the industry’s shift towards sustainability and efficiency.

What is the electrical system of the Internal Combustion Engine?

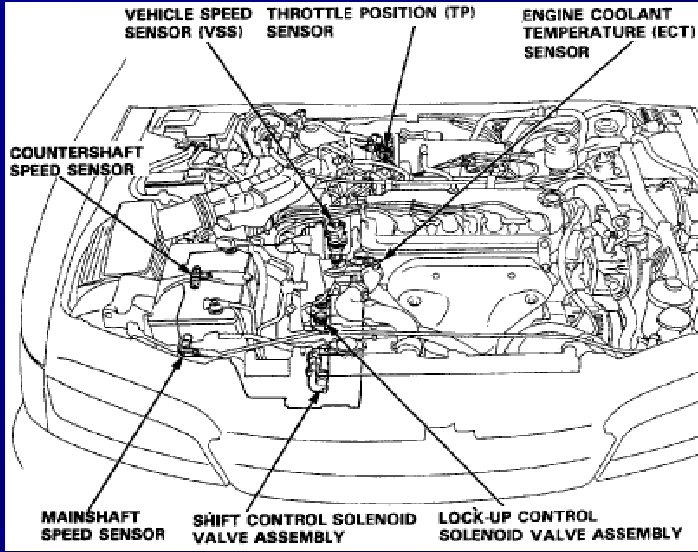

The engine’s electrical and electronic system is a critical component of modern vehicles, comprising various components such as sensors, valves, actuators, power supply and data transmission cables, the ignition system, drive-by-wire system, and variable cylinder management. These components work together to ensure the engine operates efficiently and smoothly. Sensors monitor various parameters such as temperature, pressure, and air-fuel ratio, providing essential data for engine management.

Initially, the automobile’s electrical system was primarily focused on ignition equipment. However, a current electrical system includes a lead-acid battery, generator, starter motor, lighting system, ignition system, and various accessories and controls.

Valves and actuators control the flow of air, fuel, and exhaust gases, optimizing engine performance. The ignition system ensures proper combustion, while the drive-by-wire system replaces traditional mechanical linkages with electronic controls for throttle and other functions. Variable cylinder management allows for deactivation of cylinders under light load conditions, improving fuel efficiency. Overall, the engine’s electrical and electronic system plays a crucial role in modern engine operation, performance, and efficiency.

Conclusion:

In conclusion, the internal combustion engine stands as a testament to human ingenuity and innovation, revolutionizing transportation and industry for over a century. From its humble beginnings in the 19th century to today’s advanced and efficient designs, this remarkable technology continues to power our world. Despite challenges posed by environmental concerns, the evolution of internal combustion engines has led to significant improvements in efficiency, performance, and emissions control.

As we look to the future of mobility, the legacy and ongoing development of the internal combustion engine remind us of its enduring impact on modern civilization and the ongoing pursuit of cleaner, more sustainable transportation solutions.