Everything you need to know about the systems engineering V-Model

What does systems engineering do?

The goal of a system engineer is to oversee the engineering, business, and management aspects of a project or system. System engineers usually work transdisciplinary to ensure a successful realization of a project and are engaged from conception to completion of a project. System engineers are also responsible for analyzing and resolving system challenges to find more productive ways to meet project needs.

What is a systems engineering example?

Systems engineering procedures are used in complex and large projects. Depending on the size and complexity of the project, will depend on the number of system engineers required to manage a project. For example, an automobile can have over 30,000 individual parts/components. As a result, a vehicle is broken down into commodities such as exterior, interior and electrical. Each commodity will have a system engineer responsible for integration/engineering/performance and cost all the part of that specific commodity. Thier also is vehicle level system engineers (program engineering managers) which ensure that all the commodity system engineers work together to achieve the program goals. To successfully execute their responsibilities, systems engineering uses a wide range of tools that include modeling and simulation, requirements analysis, and meetings to manage complexity..

What industries use the V-Model?

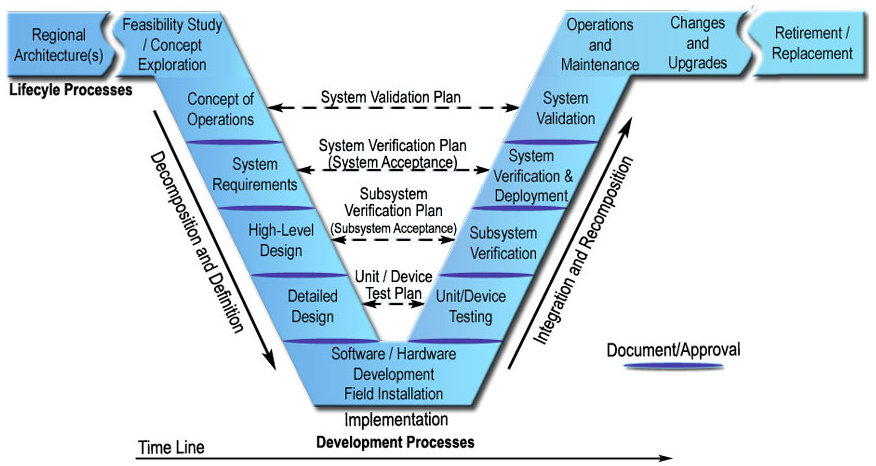

V-Model is one of the widely used by various industries such as automotive, aerospace, computer and robotics. The V-Model is a system engineering approach that was developed by the German government for planning and implementing system development projects. The V-Model is a high-level overview of the entire lifecycle of a project, laid out in an easy to view format.

How is the V-Model used in system development?

The V-model is a representation of system development that highlights verification and validation steps in the system development process. System engineers follow the V model from the initial concept to end of production. It looks at both technical and economic aspects to develop a system or project that meets the customers’ needs. The left side of the ‘V’ describes the steps that lead to definition and requirements of a project, its systems and its subsystem. The right side of the “V” describes the steps for integrating and validating each subsystem, system, and project.

Describe 10 characteristics of the systems engineering “V” model specific to the automotive industry.

The system engineering “V” model is used to show all the key steps in the product life cycle. The 10 characteristics of the system engineering “V’ model are:

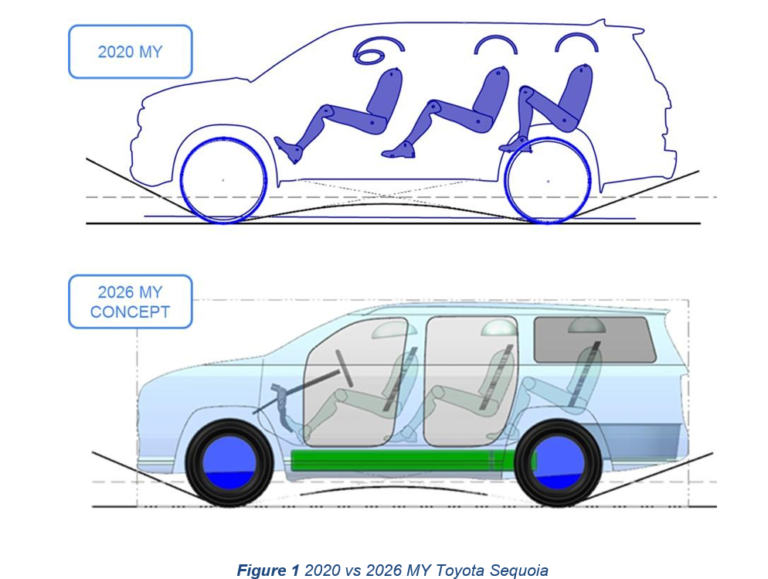

- Advanced design and planning– during this stage the general assembly is created, establishing the vehicle’s preliminary architecture and characteristics. Some of these characteristics include but are not restricted to vehicle type (architecture) the propulsion system (ICE vehicle or BEV) and the location of the drive wheels (FWD, RWD, AWD). The performance targets are also developed as well as the expected market and a list of references and competitive vehicles it will compete against in the market.

- Vehicle concept- during this stage the goal is to understand the design and engineering challenges. A business plan is created which covers the projected sales volume, the planned life of the new vehicle, the vehicle program timing, the location(s) this vehicle will be built and the tooling plan, and the financial plan (expected cost, required capital, projected revenue, estimated profit). This all information is presented to senior management to get consent before proceeding.

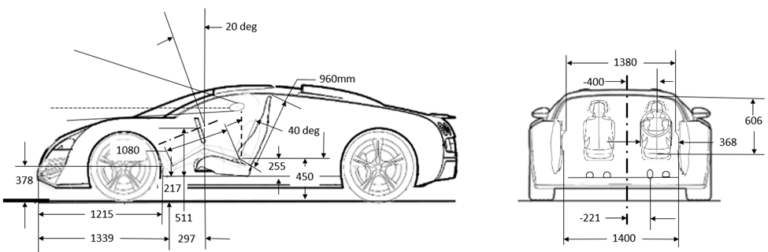

- Product concept – during this stage individual designers and integration engineers work with various engineers to create the vehicle concept. This involves the following 3 steps, creating 2D (typical sections) and full 3D CAD models with the best assumptions. Creating full vehicle renderings or videos, which portray what the vehicle would look like in actual life. Finally, also creating physical mock-ups such as seating bucks which engineering and upper management can physically touch and sit in. These seating bucks can be made from foam, clay wood, or fiberglass combinations.

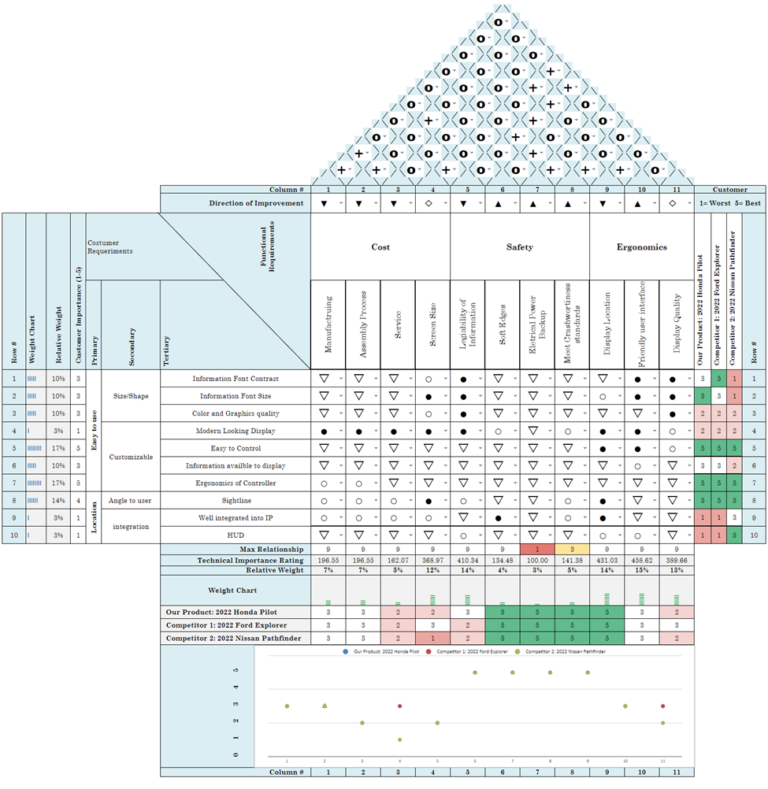

- Systems–during this step, each engineering team is working on their vehicle system can be configured to fit within the vehicle based on exterior and interior styling requirements. The teams are also working to see how the various systems interface with each other to meet all functional, ergonomics, quality, and safety program requirements.

- Subsystems- during this phase engineers being to create a more detailed design of the subsystems inside of each system. This step is straddled in time with the systems step.

- Components– during this phase engineers being to create a more detailed design of the components inside of each subsystem. This step is straddled in time with the subsystems and systems step. During this step, you also manufacture components and test that they meet their functional characteristics and requirements.

- Assembled subsystems– Components are assembled to form subsystems, which are tested to ensure that they meet their functional characteristics and requirements.

- Assembled systems-subsystems are assembled to create systems and tested. Corresponding assemblies are also tested to make sure they meet their functional characteristics and requirements.

- Assembled product– systems are assembled to create a vehicle. These initial vehicles are the first drivable prototypes. These first vehicles are tested to make sure the vehicle meets its characteristics and requirements. Issues that may arise are pushed back to the corresponding component, subsystem, or system to correct before the start of regular production.

- Operation and refinement– vehicles are produced and shipped to dealerships and sold. During this period vehicles are purchased, used, and maintained by the customers and serviced by the dealerships. Vehicles may also be refined with a minor or major update.

- Retirement and disposal– the vehicle is pulled from the market, which marks the end of the production of the vehicle. The assembly plant and all the equipment and tools are recycled or retooled for the next vehicle cycle.

References:

- Tim Weilkiens, CHAPTER 1 – Introduction, Editor(s): Tim Weilkiens, The MK/OMG Press,

Systems Engineering with SysML/UML, Morgan Kaufmann, 2007, Pages 1-22, ISBN 9780123742742,

https://doi.org/10.1016/B978-0-12-374274-2.00001-8.

(https://www.sciencedirect.com/science/article/pii/B9780123742742000018) - Automotive Product Development: A Systems Engineering Implementation, by Vivek D. Bhise. ISBN: 978-1-4987-0681-0. Publisher: CRC Press, Boca Raton, FL: CRC Press, 2017. (APD)