The Automotive Ignition System

Introduction

Automotive ignition system are designed to igniting the fuel-air mixture in gasoline engines. In spark ignition versions of internal combustion engines, the ignition system generates a spark to ignite the fuel-air mixture just before each combustion stroke. Unlike the Automotive ignition system, the ingition system used in gas turbine engines and rocket engines typically is only used during start-up.

Diesel engines utilize compression ignition, igniting the fuel-air mixture using the heat of compression and thus not requiring an typical ignition system in gasoline engine’s. They often feature glow plugs that preheat the combustion chamber to assist starting in cold conditions.

Early automobiles utilized ignition magnetos and trembler coil systems, which were later replaced by distributor-based systems (first introduced in 1912). Electronic ignition systems (first used in 1968) became prevalent toward the end of the 20th century. With coil-on-plug versions of these systems becoming widespread since the 1990s.

What is Automotive Ignition System?

The primary function of an automotive ignition system is to ignite the air-fuel mixture within a gasoline engine. Apart from the spark plugs that create sparks within the combustion chambers, the ignition system comprises an ignition coil, which elevates battery voltage to a higher level, and the spark plug wires that connect these elements. Although there is a wide variety of ignition systems available today, most can be categorized into one of three groups:

- Conventional breaker-point ignition (used since the early 1900s)

- Electronic ignition (popular since the early 1970s)

- Distributorless ignition (introduced in the mid-1980s)

Port-Fuel Injection (PFI) system vs Gasoline Direct-Injection (GDI)

The port-fuel injection (PFI) system has been widely utilized in gasoline engines and has seen decades of improvement. Although the gasoline direct-injection (GDI) system has gained popularity recently for various significant reasons, interest in the PFI system has resurfaced due to its superior ability to reduce particulate number (PN) emissions. Studieshave identified a significant amount of particulate matter emissions from GDI engines.

Some studies have proposed fuel blending with either gaseous or higher-octane fuels to improve combustion and reduce emissions in gasoline engines. Additionally, cold-start performance has become more critical due to the increasing frequency of engine restarts in advanced powertrain applications. This is due to stop-start systems used on mild-hybrid powertrains. Gasoline PFI engines often produce high CO and HC emissions during cold starts. This is because of a rich air/fuel mixture, lower catalyst conversion efficiency, and poor fuel economy due to increased friction and incomplete combustion. As a result, efforts have been made to enhance PFI gasoline engines with advanced injection systems.

What does the Automotive Ignition System circuit do?

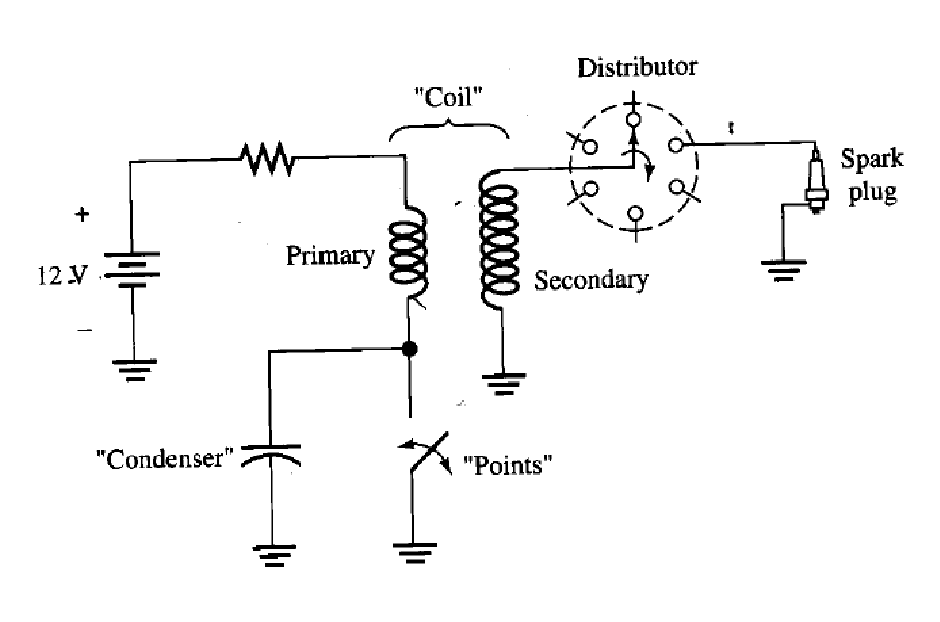

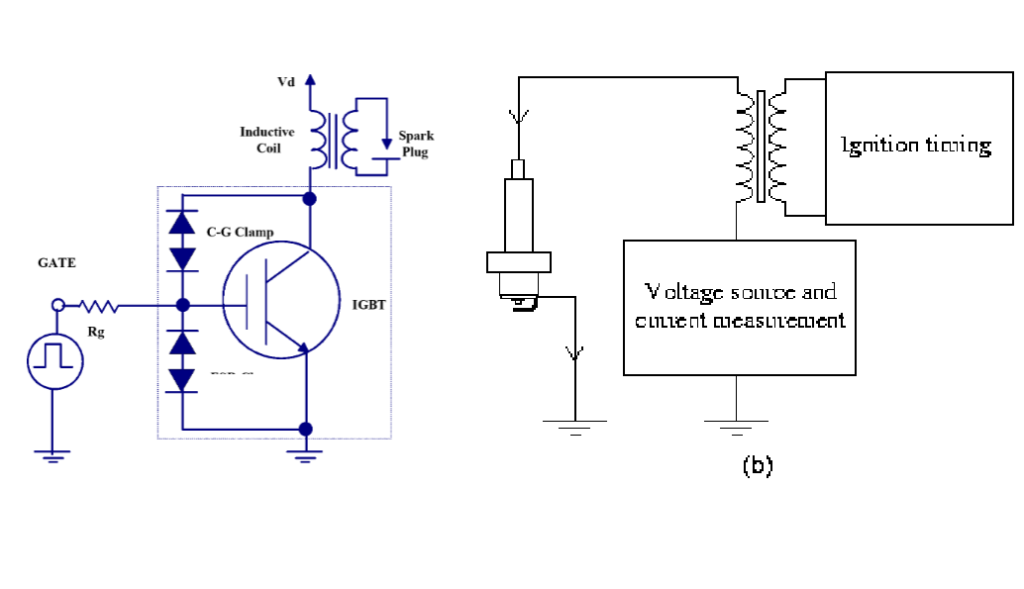

The ignition circuit is an example of a second order RCL circuit. The ignition circuit is responsible for producing and delivering the electrical spark needed to ignite the fuel-air mixture in an engine’s cylinders. It consists of components like the ignition coil, distributor (or electronic control unit), spark plug wires, and spark plugs to form a spark at the airgap to ignite the gas-air mixture.

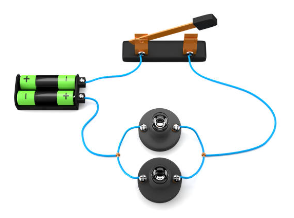

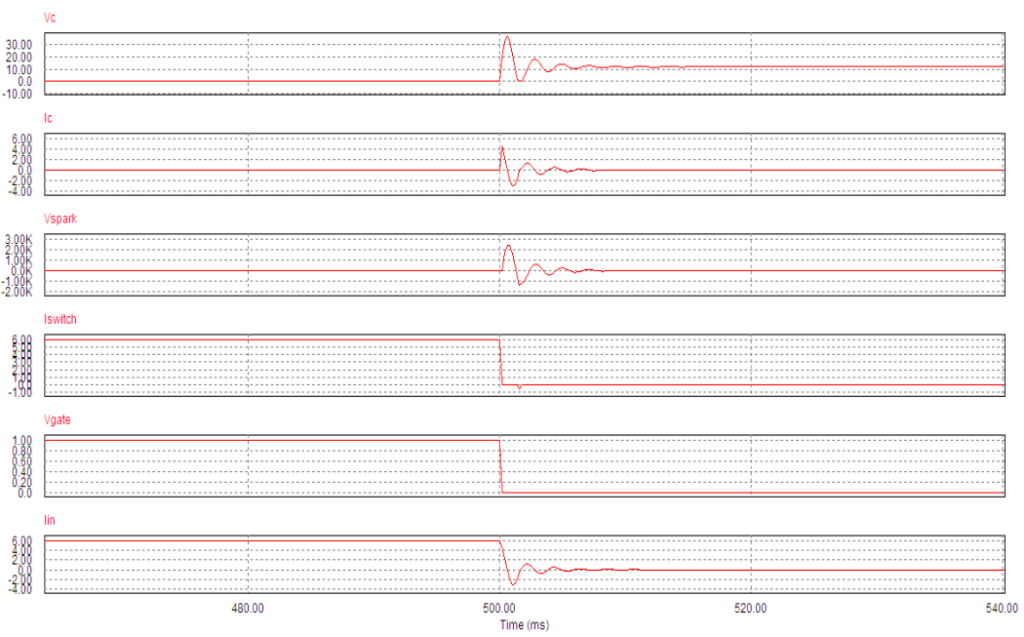

When the switch is closed the primary of the transformer is charged with a current in the circuit. When the switch is open, the current is interrupted and energy in the primary is transferred to the

secondary.

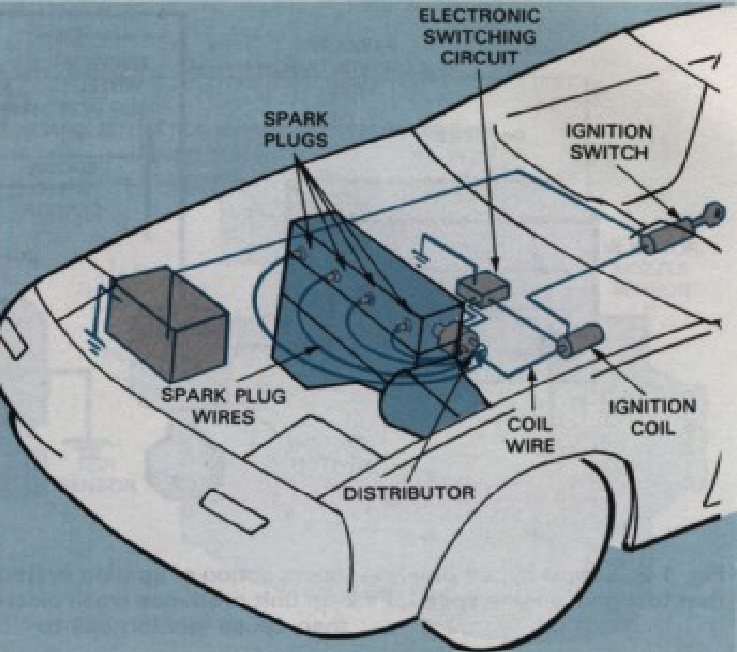

What is distributor-based Automotive Ignition System?

Back in the old days, cars used a point/distributor-based ignition system. This system relied on a mechanical method to open and close the circuit (make and break the primary circuit) that delivered the spark to the engine.

This system consisted of a distributor, a rotor, and ignition points. The distributor rotates and distributes high-voltage electrical current from the ignition coil to each spark plug in the correct firing order. The ignition points open and close to trigger the spark at the right time.

However, modern vehicles have largely replaced distributor-based systems with more advanced electronic ignition control systems for improved reliability and performance. Some of the draw backs on an older distributor-based ignition system are – it required a lot of maintenance to keep the points clean and properly adjusted, and it wasn’t very reliable in wet or humid conditions.

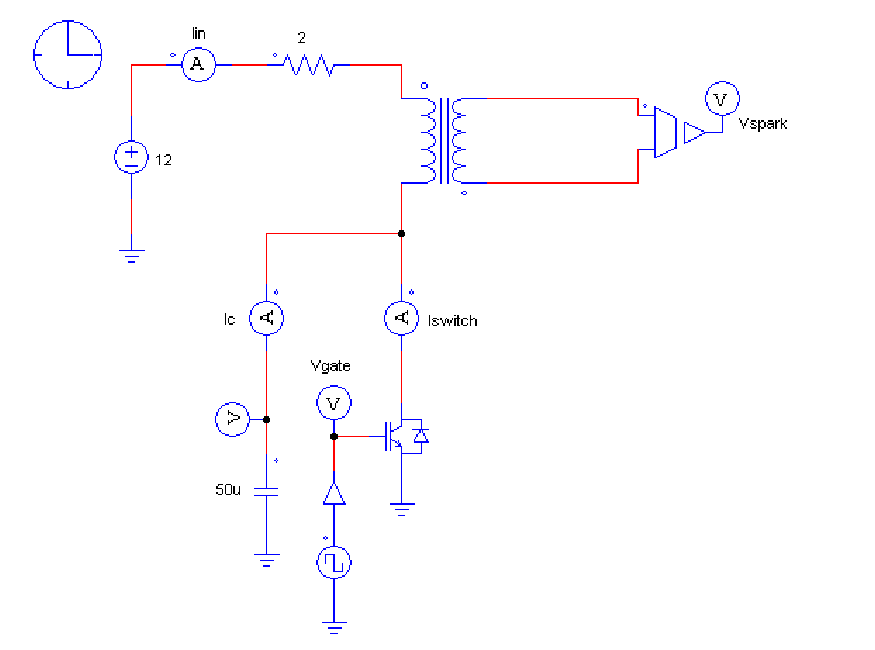

Simulation of a Ignition Circuit using PSIM

Results of a PSIM Simulation:

Components of an Electronic Ignition Control System

Electronic ignition control systems were developed to address these issues. These systems use solid-state electronics to control the timing and delivery of the spark, eliminating the need for mechanical switches and improving the reliability and efficiency of the system. Generally one of the two cylinders is in compression stroke, where spark will cause the air fuel mixture to explode. Other cylinder not in compression mode, will have no effect due to the presence or absence of the spark. Engines normally (there some exceptions, though not common) are in even number of cylinders (4 cyl, 6 cyl, 8 cyl), so the above concept works ok.

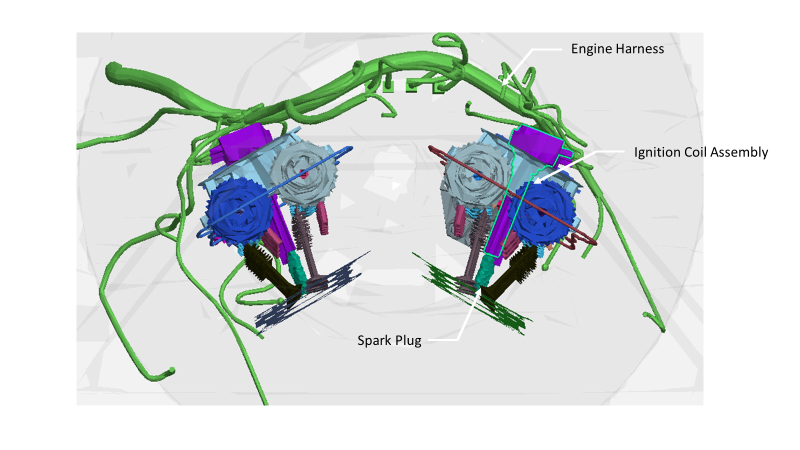

Now, let’s dive into the components of an electronic ignition control system. There are a few main components that work together to produce and deliver the spark to the engine: the ignition coil, the distributor (controller), the spark plug wires, and the spark plugs.

The ignition coil converts the 12-volt electrical current from the battery into the high-voltage current required to produce the spark. It achieves this by sending a large current through an inductance and interrupting it after building up in the primary circuit. This interruption induces a very high voltage in the secondary (S) of the coil, which is connected to the spark plug terminals.

The distributor is a rotating part that distributes the spark to the correct spark plug at the right time, based on the firing order of the engine. The spark plug wires connect the distributor to the spark plugs, delivering the spark to each plug. And the spark plugs themselves are responsible for actually igniting the fuel in the engine.

How Electronic Ignition Control Systems Work

Now that we understand the components of the system, let’s talk about how electronic ignition control systems actually work. Essentially, internal combustion engines depends on the spark timing based on engine position during the compression stroke.

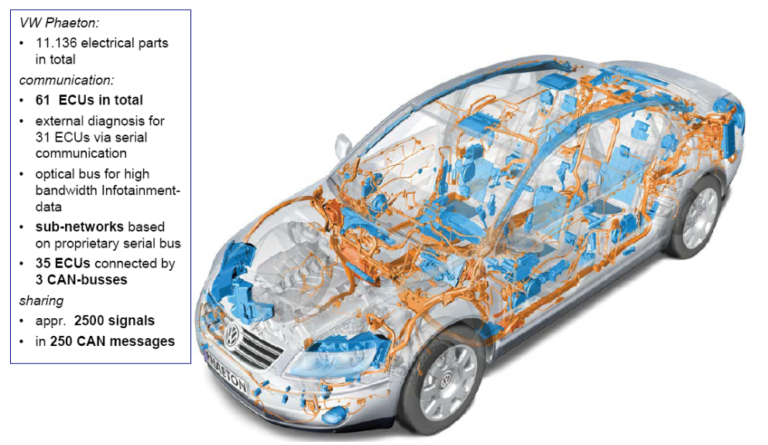

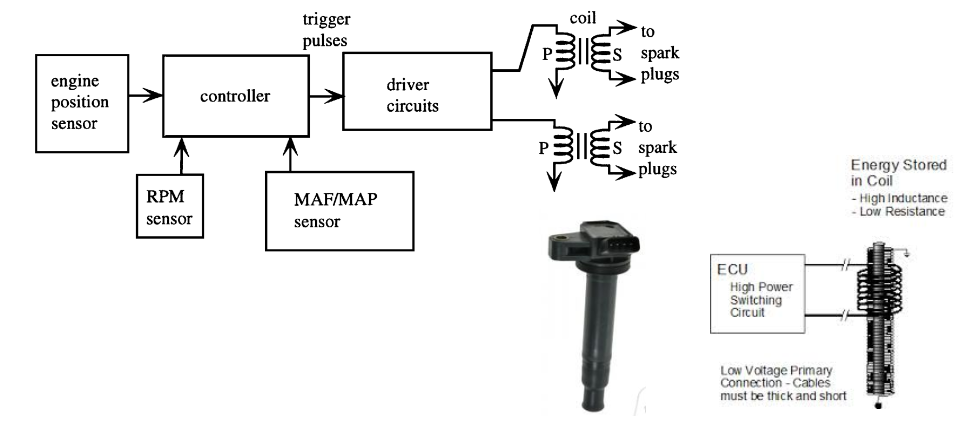

As a result, the system uses a series of sensors to determine the engine’s position (relative to top dead center [TDC]), speed (RPM), manifold pressure and engine temperature. It then uses this information to trigger the spark at the right time. Electronic ignition can be part of an integrated system or it can be a stand alone ignition system.

There are a few different types of electronic ignition control systems, but they all work in roughly the same way. In a distributor-based system, the distributor uses a series of contacts and a rotor to distribute the spark to each spark plug in the correct firing order. In a distributorless system, the spark is delivered directly to each spark plug by an individual coil pack. And in a coil-on-plug system, each spark plug has its own individual coil, eliminating the need for a distributor altogether.

Each type of system has its own pros and cons. Distributor-based systems are the most common and generally the most affordable, but they can be less reliable than distributorless or coil-on-plug systems. Distributorless systems offer improved reliability and performance, but they can be more expensive. Coil-on-plug systems are the most reliable and offer the best performance, but they can also be the most expensive.

What is electronic engine control EEC?

The Electronic Engine Control (EEC) system utilizes sensor data on engine position, mass air flow, manifold pressure, and RPM to calculate the correct spark advance for each cylinder. The controller then sends a signal to the corresponding ignition driver circuit, initiating the spark. In many modern electronic spark systems, spark plugs are fired in pairs through a common coil or high-voltage transformer. This technology replaces older mechanical systems, such as carburetors and distributor points, with computer-controlled systems that offer more precise and efficient control over the engine’s operation.

Benefits of Electronic Ignition Control Systems

So why are electronic ignition control systems so important? Well, for starters, they offer a number of benefits over traditional points-based ignition systems. For one thing, they’re more reliable and require less maintenance. They also offer improved fuel efficiency and reduced emissions, which is great for both the environment and your wallet. And perhaps most importantly, they offer increased power and performance, which is always a good thing for car enthusiasts.

Common Problems with Electronic Ignition Control Systems

Like any complex system, electronic ignition control systems can encounter problems from time to time. Some common issues include misfires, poor fuel economy, stalling, and starting problems. Fortunately, many of these problems have relatively simple diagnoses and fixes. For instance, a misfire might result from a bad spark plug or a faulty ignition coil, both of which are easily replaceable.

Conclusion

In conclusion, automotive ignition system is a vital component of any modern car. Understanding how automotive ignition system works is crucial for anyone who wants to keep their vehicle running smoothly. By using solid-state electronics to control the timing and delivery of the spark, these systems offer improved reliability, efficiency, and performance over traditional points-based ignition systems. And while they can experience problems from time to time, many of these issues can be diagnosed and fixed with relative ease.