Metalworking Basics Explained

Metalworking is the art of shaping metals into various tools, equipment parts, and structures. It involves forming, cutting, and joining metal pieces using techniques like welding, casting, and molding. In the industrial age, metalworking has developed into a sophisticated science. The industrial revolution has led to exponential growth in the scale of modern metalworking processes, accompanied by increasingly complex technologies.

However, this craft has been practiced for millennia, with evidence dating back to 8,700 BCE in Iraq. Ancient civilizations such as the Egyptians and Mayans valued and crafted objects from precious metals.

What are the different types of metalworking?

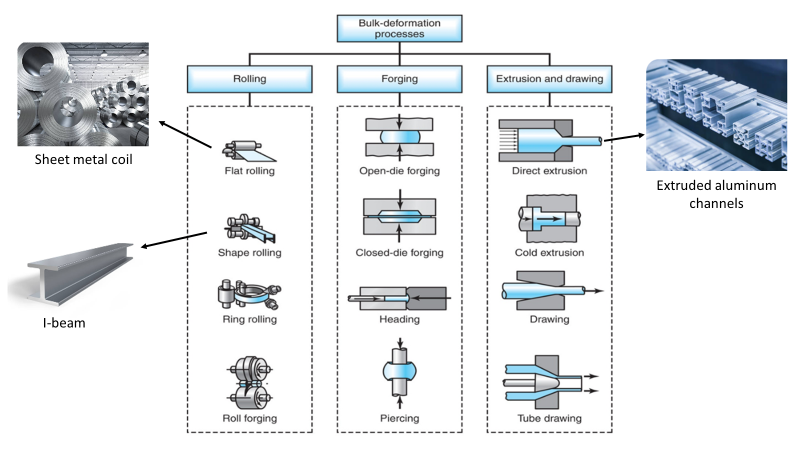

Metalworking is the manufacturing process of shaping/reshaping metals to create useful parts, assemblies, and structures. All metalworking processes can be divided into 3 main categories: rolling, forging, and extrusion/drawings.

In bulk-deformation process a simple part, typically a metal billet or sheet blank, is plastically deformed between tools (or dies) to achieve the desired final shape. This process transforms a basic initial geometry into a more complex one, with the tools “storing” the intended geometry and applying pressure to the material through the tool/material interface.

Bulk-deformation processes typically produce minimal to no scrap and achieve the final part geometry quickly, often in just one or a few strokes of a press or hammer. These processes are known for their significant energy and material savings.

What tools do you need for metalworking?

Various tools and equipment are necessary for different metalworking processes. These can include molding, drilling, casting, welding, cutting, and more. Common tools for metalworking include a bandsaw, hacksaw, welder, angle grinder, belt sander, and drill press. It’s crucial to fully understand the safe operation of these tools before starting any project.

What’s the difference between metalworking and blacksmithing?

Blacksmithing is a subset of metalworking, which encompasses various methods like welding, casting, and jewelry making. It involves using a forge, hammer, and anvil to shape metals, particularly iron and steel. The origins of welding can be traced back to early blacksmithing techniques around 3000 BCE.

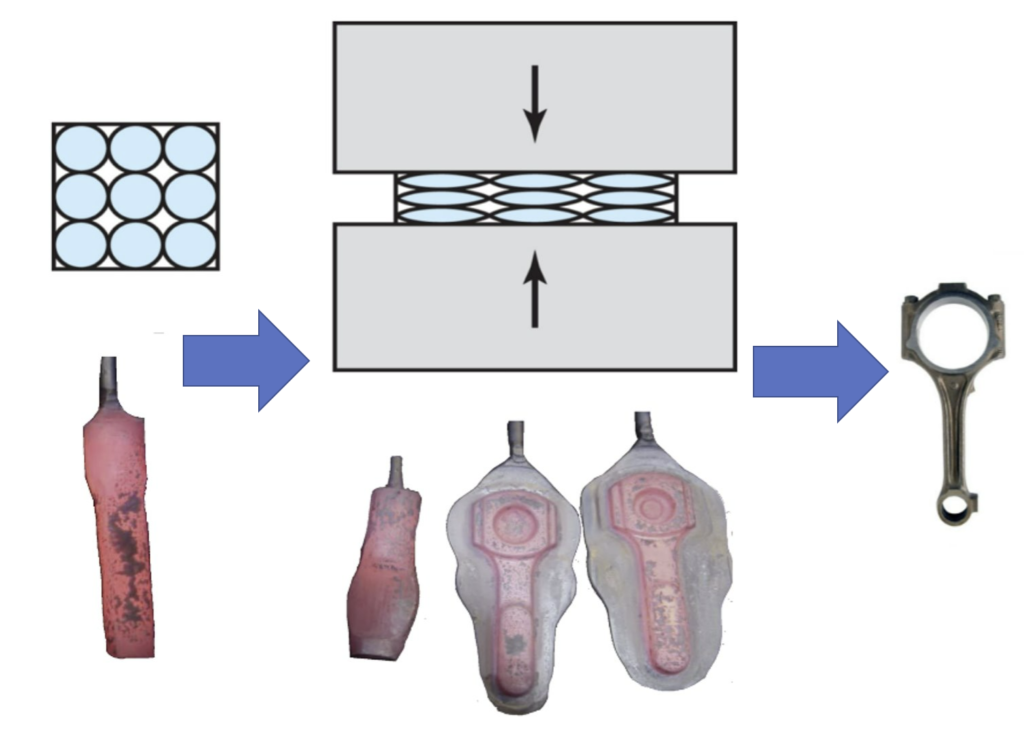

What automobile parts are made by forging?

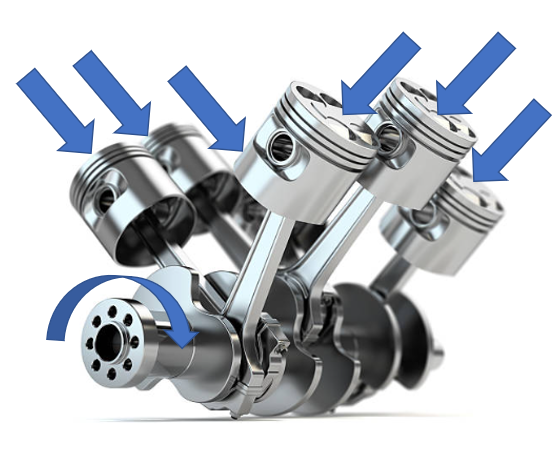

Forging is a manufacturing process, that uses compression to shape metal parts. Forging is one of the oldest manufacturing processes which dates back to well before 4000 BC. The first metals forged here were gold, iron, and copper alloys such as bronze. An area where forged parts are still used extensively is the powertrain system in the automotive industry. Several of the key components in this system require parts to be forged to be able to withstand the significant loads that will be experienced in the engine and transmission. Some examples of forged parts in a vehicle powertrain system include connecting rods, crankshafts, transmission shafts, and gears.

What are the advantages of forging over casting?

As a result of the tight grain structure which is a result of the compressive load of forging, forged parts are stronger than cast parts. Forged parts are not susceptible to cavities, cold pour problems, porosity, or shrinkage.

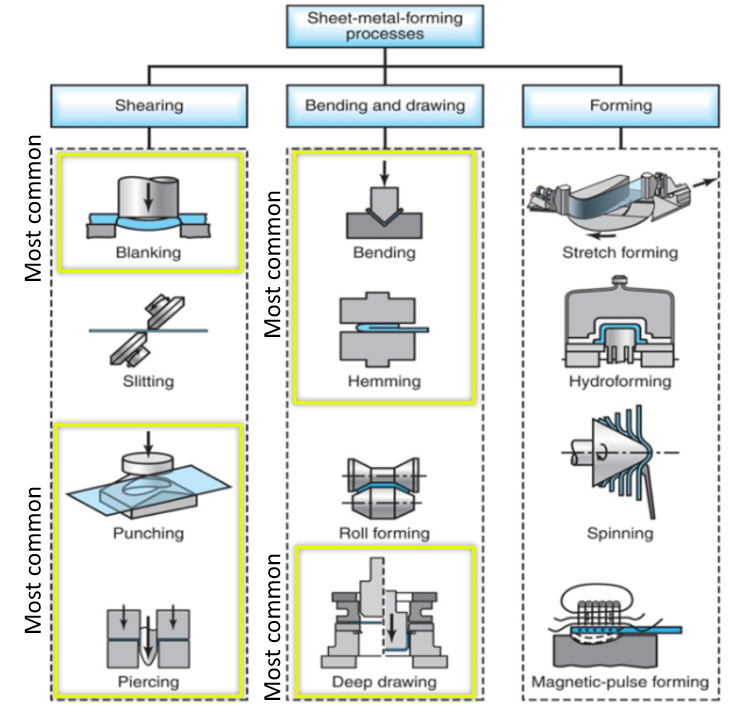

What are the basic types of sheet metal processes?

After the metal has been flat-rolled it is usually coiled into giant rolls which then can be used to fabricate sheet metal parts. The three major categories of sheet-metal processes are shearing, bending/drawing, and forming. In the automotive industry, most sheet metal parts are either sheared or bent/drawn to achieve the final design.

What is the forming process for car manufacturing?

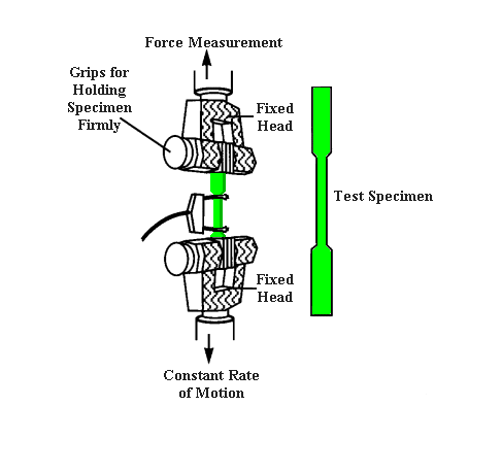

Using the stress-strain diagram automotive engineers ensure they exceed the yield stress of a material while avoiding ultimate stress. This ensures that the part is within the plastic deformation zone while stamping. The reason to exceed the yield stress of a material is to ensure that the part will hold its intended shape after the die opens up, if the yield stress is not exceeded the part will go back to its original shape. However, automakers must be careful not to exceed the fracture stress as this will result in a tear or crack in the sheet metal.

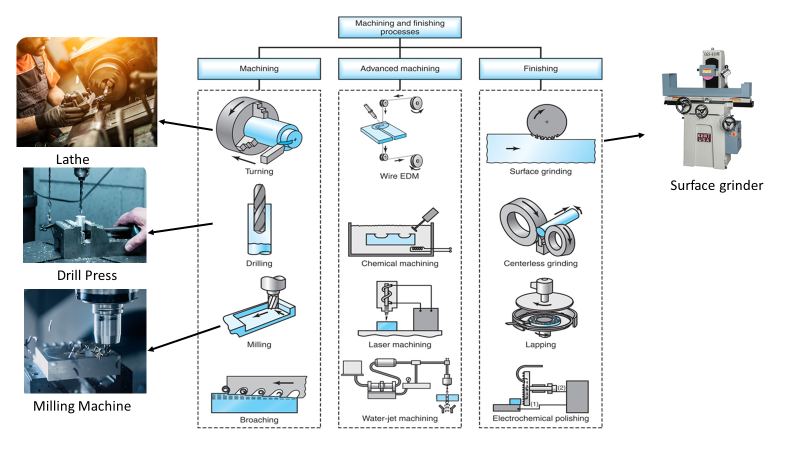

What is the machining and finishing process?

Usually, most companies stamp, forge or cast the majority of their parts before conducting any machining or finishing operation. If machining or finishing is required the cost of the part skyrockets, especially as the dimensional tolerance gets tightened up. For this reason, many companies try to design around these manufacturing processes.

Machining is the process of cutting or removing material from the workpiece. The most common type of machining operations are turning, milling, or drilling. During the finishing process, less material is cut or removed from the material, when compared to milling thus the part ends up with greater tolerances and a nicer surface finish. Many times finishing is done to improve the appearance or the feel of a part.

What is the heat treatment process?

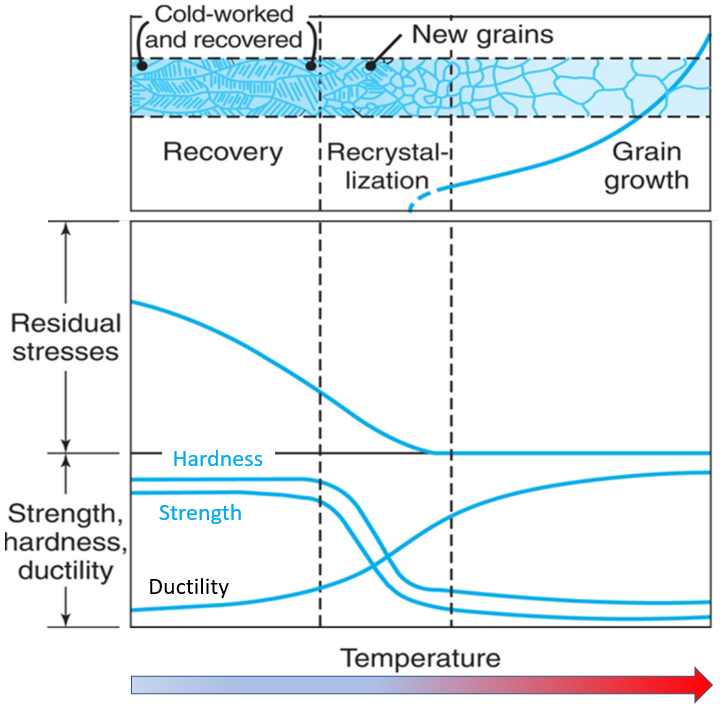

Heat treatment is a type of property modification process in which metal or metal alloy is heated to enable recrystallization of the metal and thus alter its material properties. Recrystallization occurs when the temperature is increased to the point where the material is glowing red hot but prior to reaching its melting point. The metal is then cooled in a controlled way to obtain the desired mechanical properties. As can be seen in the graph below the hardness and strength of a material are inversely related to the ductility of the material.

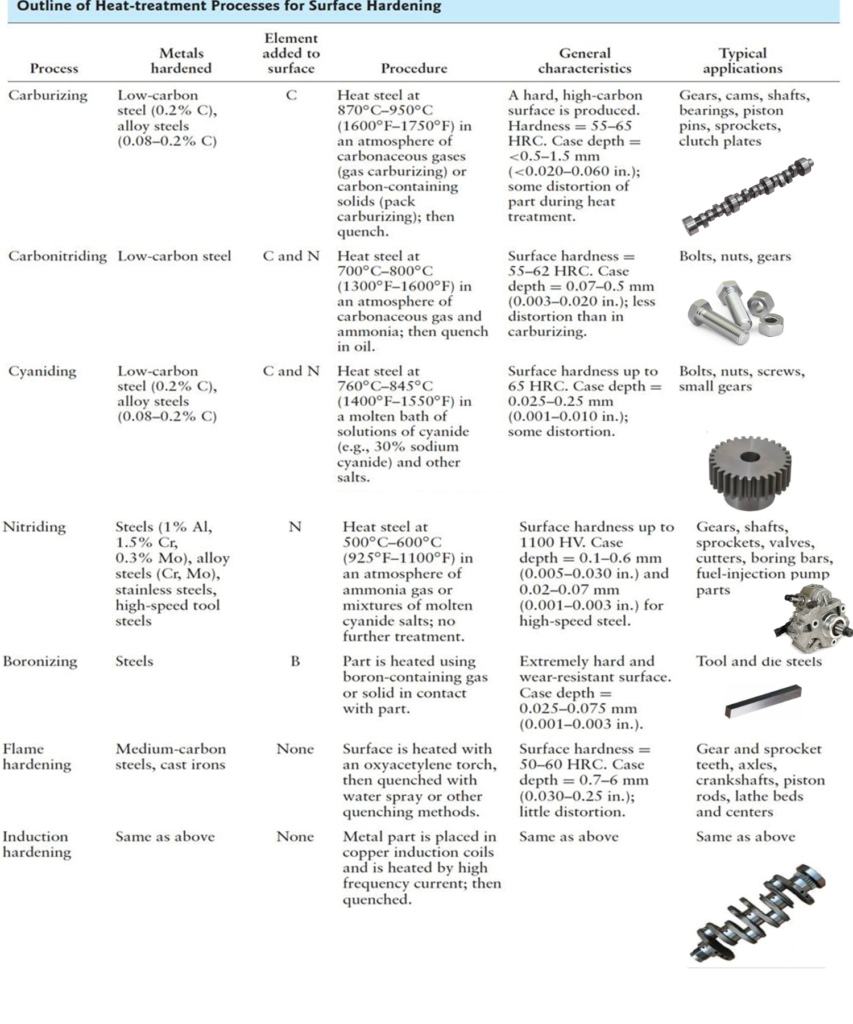

What are the different types of surface heat treatment?

Surface heat treatment is a type of heat treatment where the outer layer of a part has a higher hardness requirement than the core of the material, some reason for needing this is for more wear resistance. See a list below of various types of surface hardening.

Conclusion

In conclusion, metalworking is a versatile and essential skill that encompasses a variety of processes, including forming, cutting, and joining metals. Understanding the basics of metalworking, such as the tools and techniques involved, can open up a world of possibilities for creating useful and beautiful objects. Whether you’re interested in crafting intricate jewelry or building sturdy structures, learning the fundamentals of metalworking is the first step towards mastering this ancient craft.