Solidification of Metal

Solidification of metal is a complex process where molten metals and alloys turn into solid forms. It includes dendrite formation, compositional segregation, zone formation in the final casting structure, and the creation of microporosity due to shrinkage.

What is Solidification

Solidification refers to the process of a substance changing from a liquid to a solid state. This transformation is evident in various everyday occurrences, such as the formation of ice and the solidifying of solder in electrical circuits. In industrial settings, solidification is crucial for the casting of metals, which is a cost-effective and vital manufacturing method. Casting finds extensive application, from the production of automotive components like engine blocks and cylinder heads to crafting individual items such as jewelry and statues.

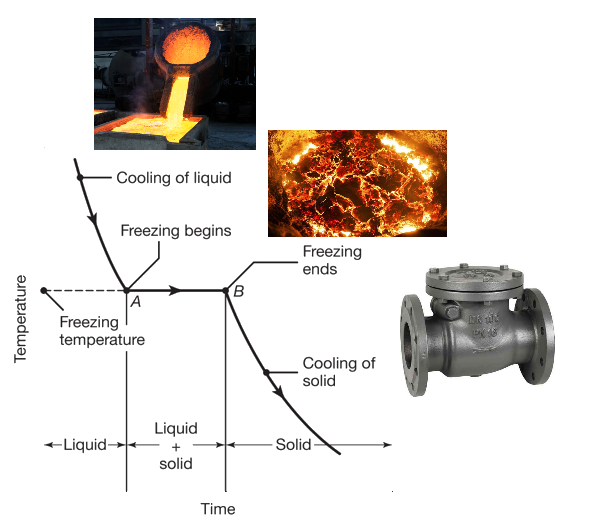

The casting process typically involves pouring liquid metal into a mold that contains a cavity corresponding to the desired final product. As the metal cools, it solidifies within the mold. This transformation occurs when the temperature drops below the metal’s melting point.

The process of solidification includes the release of latent heat, requiring the heat transfer from the liquid metal to its surroundings. In the case of an alloy or impure metal, the compositions of the solid and liquid phases are typically different. Thus, solidification also involves the transportation of alloy elements, often referred to as solute.

What is pouring molten metal called?

The pouring of molten metal into a mold is also known as casting. Metal castings are produced in special factories called foundries. The molten metal must completely and properly fill the mold cavity prior to hardening. To ensure proper solidification of the metal, the engineers play with the pouring temperature and pouring rate to minimize turbulent flow while pouring the molten metal.

Why is fluidity important in the solidification of metal?

During the casting process, it is extremely important to ensure that the metal has the proper flow rate and thermal characteristics (heat transfer rate). These two parameters can affect the overall soundness and surface features of the final product.

The following affect fluidity, fluid flow, and thermal characteristics of the system:

- Mold Design

- Mold material and it’s surface characteristics

- Degree of superheat

- Pouring rate

- Adding chills to increase the heat transfer rate

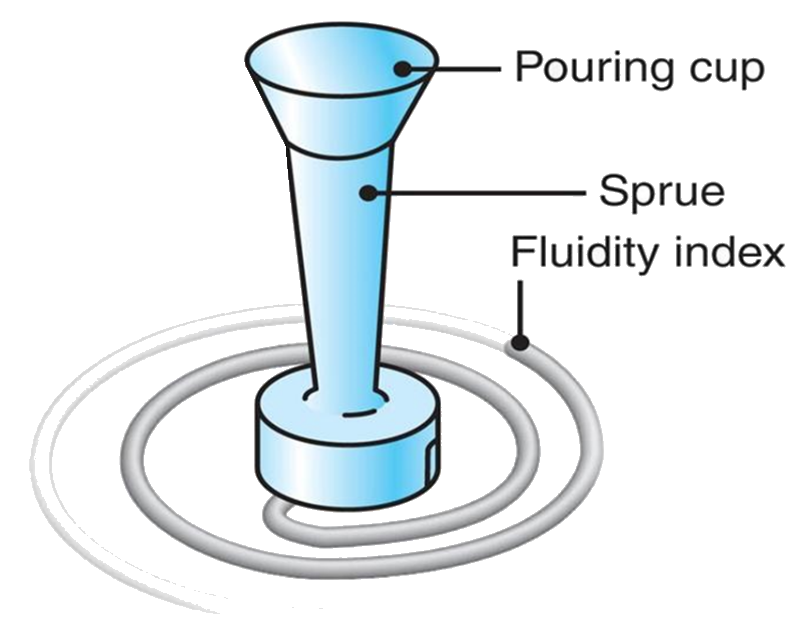

What is the spiral fluidity test?

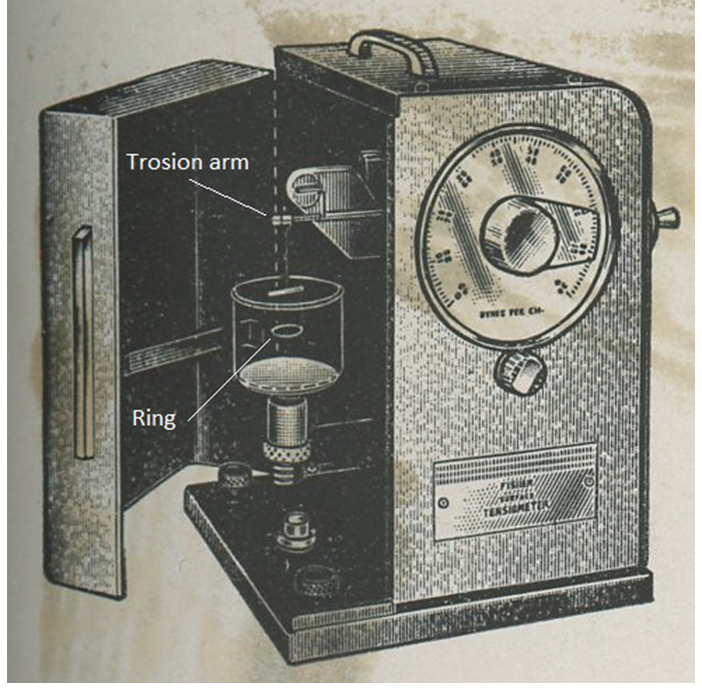

The most popular fluidity test used in foundries is the spiral fluidity test. The fluidity index is measured by the length of the solidified metal in the spiral mold cavity. The greater the length of the solidified metal, the greater the metal’s fluidity.

Why should turbulent flow be during the solidification of metal?

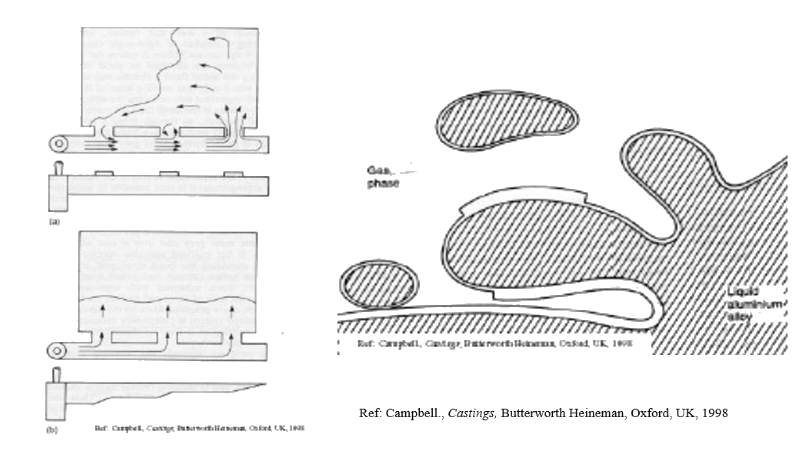

Turbulence flow can occur when the metal is poured too quickly into the mold. Ideally, the molten metal should flow in a laminar flow regime. Turbulent flow is extremely hard to predict due to its inconsistencies and irregular variations in speed and direction.

The two factors which affect if the liquid metal will be laminar or turbulent as it travels through the casting are the mold geometry and the flow speed. Turbulent flow can lead to mold erosion which is caused by random impacts of the liquid metal, these impacts are amplified by the high density of the liquid metal. Another problem with the turbulent flow during the casting process is that gas bubbles could get trapped in the cast part leading to defects such as porosities.

What is the Process of Solidification of Metal?

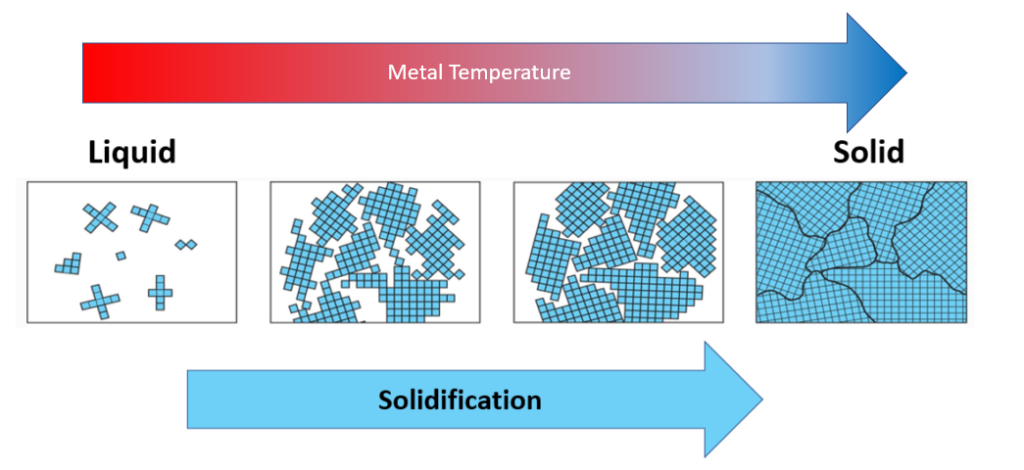

Solidification is a process in which atoms are transformed from a disordered liquid state into an organized solid state. At first, nucleation appears in the liquid metal, these nuclei then grow as more atoms that are in the liquid state are attached to solid nuclei. The center of the nuclei will eventually become the center of the metal crystal/grain which is formed. The process continues to repeat itself until the whole metal is solid.

What is meant by Solidification of Metal in Casting?

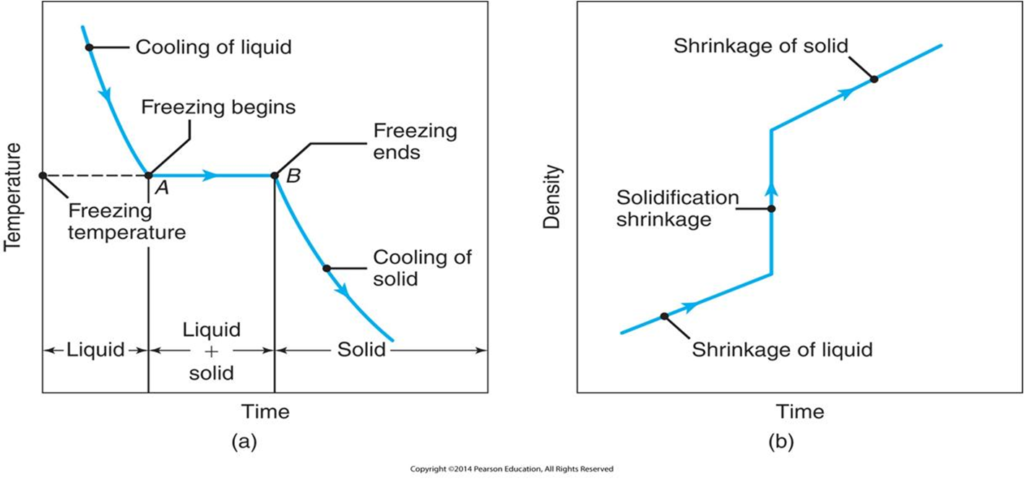

Solidification is the growth of favorably oriented nuclei toward heat extraction. During the solidification process, there is a liquid contraction, also known as shrink cavities (pipe) thus is a result of a low supply of fresh liquid metal. As the metal cools, randomly oriented small grains form near the mold walls while columnar grains form towards the center of the mold. The contraction of liquid metal separates the cast and mold surface, forming an air gap. This behavior is known as which as liquid shrinkage.

What is the solidification of eutectic?

Similar to pure metal, the solidification of a eutectic metal alloy, which comprises 2 or more metals, occurs at a constant temperature. Eutectic cells form inside the grains as the eutectic alloy solidifies.

The properties of the eutectic metal alloy cast part are affected by:

- Cooling rate

- Nucleation agents

- Alloy modifications

What does Chvorinov’s rule tell us?

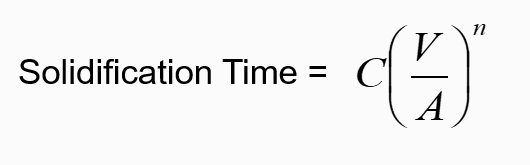

Chvorinov’s rule suggests that the volume-to‑surface area ratio affects the solidification rate. The higher the volume-to-surface area ratio, the longer the casting will take to solidify. The riser needs to have a larger volume‑to‑area ratio than that of the main casting, so they are the last part to solidify. Such hot spots inside the mold cavity should be avoided when designing castings because they are potential sites of porosity defects.

volume-to‑surface area ratio can be calculated with the equation below where V = volume of the casting; A = surface area of casting; n = exponent usually taken to have a value = 2; and C is mold constant

What causes solidification shrinkage?

Shrinkage occurs because, for most metals, the density of the solid phase is higher than that of the liquid phase. This results in shrinkage (reduction in volume per unit mass) upon solidification. A shrinkage cavity is a depression in a casting, which occurs during the solidification process. Shrinkage porosity appears with angular edges compared to the round surfaces of gas porosity. For this reason, the riser should be the last part of the mold to solidify, so any defect and imperfection are forced onto the riser.

However, there are exceptions to this rule, for example, the graphitization of carbon in cast irons with high carbon content. During the solidification process, the carbon increases in volume. This increase counteracts the shrinkage experienced by iron; thus, cast iron alloys do not show solidification shrinkage.

What are the advantages of the rapid solidification process?

The advantages of rapid solidification are:

- Smaller microstructural features

- Smaller & more uniformly dispersed porosity and intermetallic

- Reduced grain size

- Improved mechanical (strength, fatigue, & ductility)

Faster solidification will not affect the morphology of inclusions during the casting process.

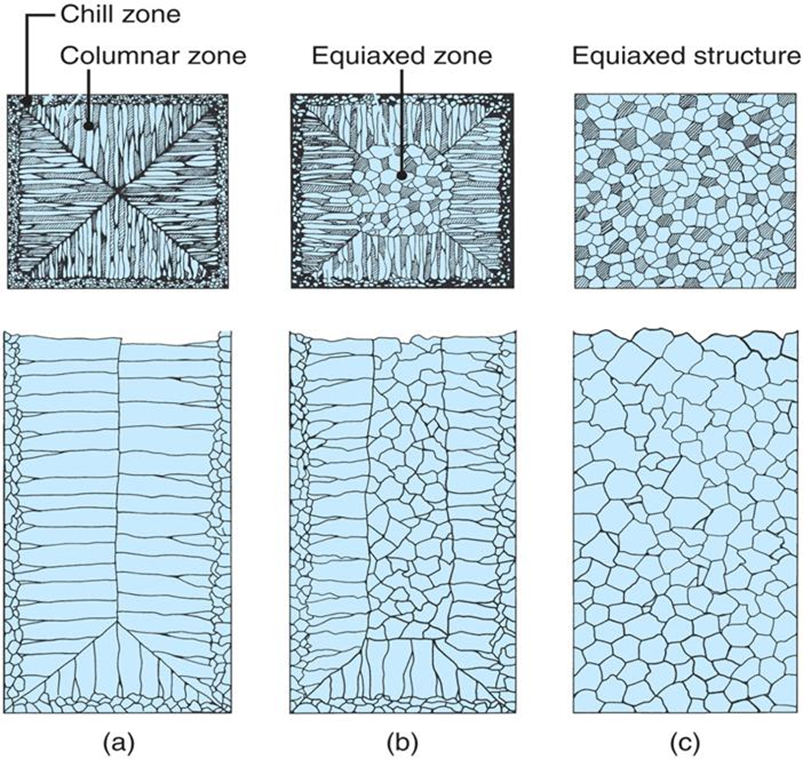

What are the three regions or zones of a cast structure?

The three regions or zones in a cast structure are:

- The chill zone–a boundary layer next to the cold mold wall of small equiaxed crystals with arbitrary orientations.

- The columnar zone–a band of elongated crystals adjusted parallel to the directions of heat transfer. Only favorable oriented grains grow away from the mold surface.

- The equiaxed zone–a central region of uniform crystals, the structure is obtained by heterogeneous nucleation of grains.

The schematic picture below shows three cast structures of metals solidified in a square mold:

What happens to the structure of a metal when it solidifies?

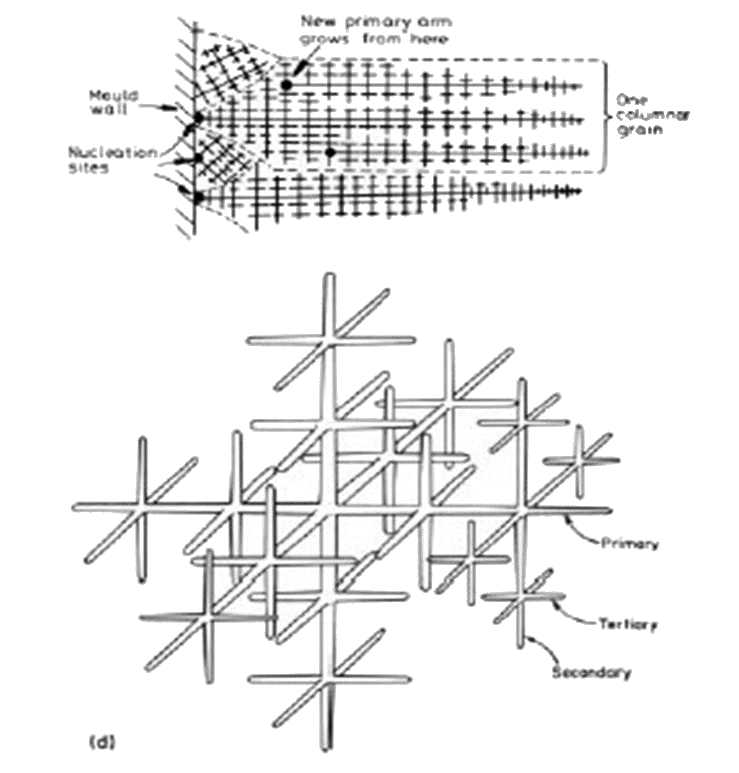

As metal solidification takes place over a freezing range, the grains grow toward heat extraction. Solidification proceeds by dendritic form, this is due to the initial solidified material having a lower alloying element concentration. As more liquid metal flows into the mold, it is possible for the dendritic arms can break off and re-melt. Dendrite growth is realized by the rapid movement of the liquid/solid interface toward the under-cooled melt. The formation of rapidly grown dendrites results in microporosity, which reduces the strength of the final cast part.

What causes dendritic solidification?

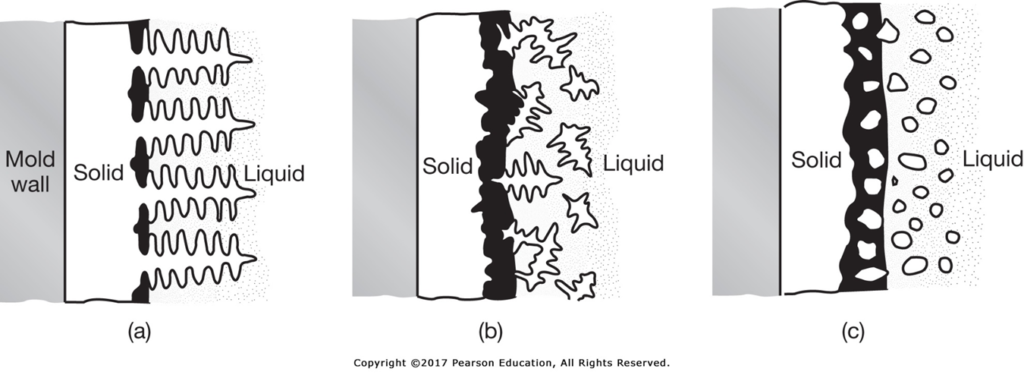

As metal solidifies slowly, dendrites begin to form and harden until the entire melt is solidified. There are three basic types of cast dendrites structures: (a) columnar dendritic; (b) equiaxed dendritic; and (c) equiaxed nondendritic.

During the casting process, it is possible to reduce/minimize the formation of dendrites by breaking dendrites. The way to break dendritic structures are:

- Vibration during solidification

- Centrifuging

- Forced flow (pressure die casting)

- Shearing (rheocasting)

- Pressure application during solidification (squeeze casting)

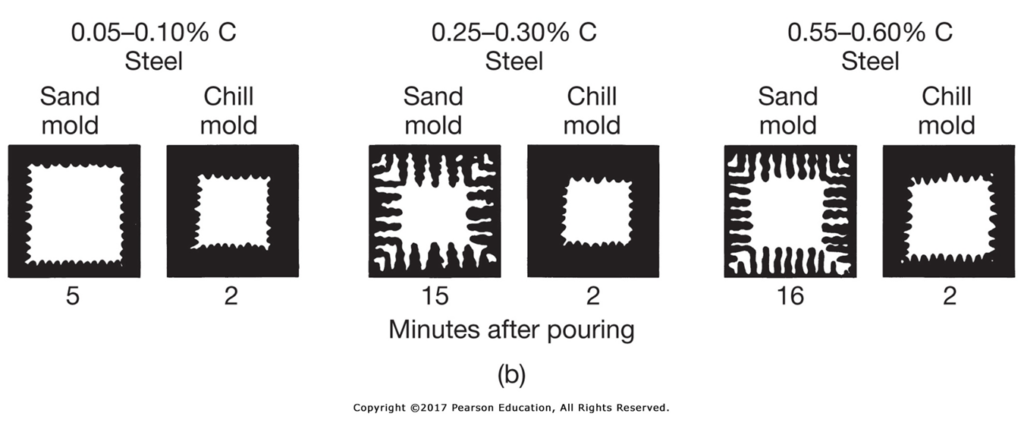

The carbon content in the steel or metal alloy can also affect the behavior of the dendritic structures. Below is an example of solidification patterns for gray cast iron 7-inch. square casting with and without chills.

Conclusion

In conclusion, the solidification of metals is a fundamental process with wide-ranging implications across various industries. From the casting of complex metal components, solidification plays a crucial role in shaping the world around us. Understanding the factors that influence solidification, such as heat transfer and alloy composition, is key to optimizing manufacturing processes and achieving desired material properties. As technology continues to advance, further insights into solidification mechanisms promise to unlock new possibilities in materials science and engineering, driving innovation and shaping the future of manufacturing.