Machining Operations Explained

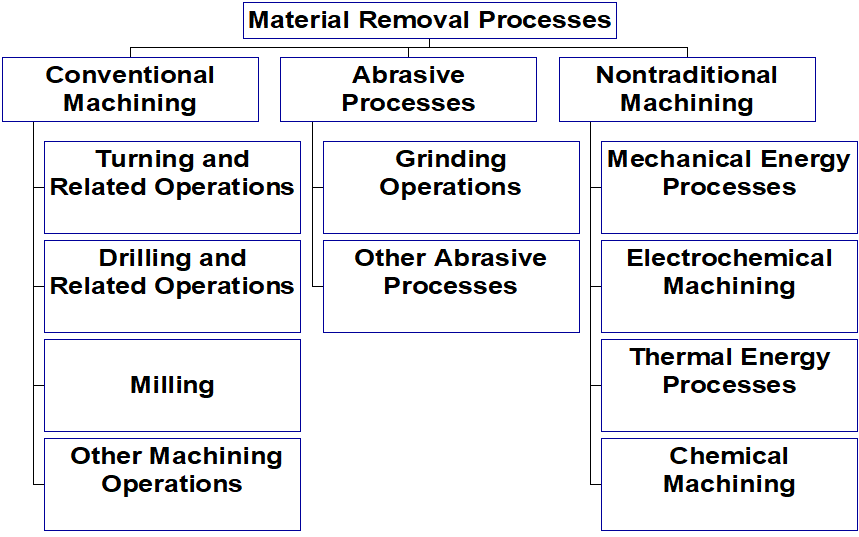

Machining is a manufacturing process that involves shaping or creating a part by removing material, typically metal, from a larger workpiece through cutting. This method is known as subtractive manufacturing, as it removes material to achieve the desired shape, unlike additive manufacturing, such as 3D printing, which adds material. Machining is crucial in producing many metal products, but it can also be used on materials like wood, plastic, ceramic, and composites.

Individuals who specialize in machining are called machinists. Machining is often carried out in a machine shop, which houses primary machine tools. While some businesses have standalone machine shops, others have internal machine shops or tool rooms to support their specific needs.

Modern machining commonly uses computer numerical control (CNC), where computers control the operation of mills, lathes, and other cutting machines. This technology enhances precision and efficiency in machining processes.

What is the basic machine operation?

What is machining? Machining is a precise and meticulous procedure that involves cutting materials to achieve the desired shape and size for creating parts, tools, and instruments. While it is commonly used with metals, machining can also be applied to various other materials. Machining Involves the use of various tools and techniques to remove material from a workpiece to create a desired shape or size. Machine shops employ machinery such as mills, lathes, and drill presses to remove material, as well as 3D printers to add material when necessary.

It might not sound that exciting, but it’s pretty important, and there are a ton of different types of material removal processes, each with its unique characteristics and applications. The 3 principle conventional machining processes are turning, drilling, and milling.

What is abrasive machining?

Abrasive machining is undeniably the oldest basic machining process, with extensive literature on the subject. This material removal process uses abrasives like aluminum oxide, silicon carbide, resin bond, and various other natural or synthetic abrasives. Chips are formed by very small cutting edges that are typically man-made and integral to the process. The process gradually removes material from a workpiece, often involving high-pressure equipment. The chips produced can be extremely small, necessitating the use of eye protection at all times.

Is machining the same as manufacturing?

Manufacturing encompasses assembly and includes the creation of machined components or parts made from machined tools. These components are typically more transportable than the assemblies they are incorporated into, making machining a process that can be easily outsourced over long distances.

Is machining considered a trade?

A machinist is a skilled professional who has been trained to manufacture tools, parts, and objects using milling and drilling machines, grinders, and lathes in a machine shop. This role demands a high level of precision, as machinists are expected to make cuts accurate to within one-thousandth of an inch.

What are the basic elements in metal cutting?

Machine Tool: provides the required energy for removing material, holds the tool and workpiece, and controls feed, speed, and depth of cut.

Cutting Tool: made of materials that are harder than the material of the work part, and has a specific geometry to shape the work part.

Workpiece: raw or pre-fabricated stock to be machined to specifications.

Cutting Fluid: A significant portion of metal cutting and forming operations are performed using MetalWorking Fluids (MWFs), as classified by the United States National Institute of Occupational Safety and Health. MWFs enhance machinability and formability by allowing higher speeds and feed rates while reducing wear and friction. They are often crucial for chip removal in machining. The use of coolants and lubricants represents a significant part of manufacturing costs and contributes to rising health insurance expenses in the sector. Cutting fluids can be applied in liquid, gaseous, or mixed liquid-gaseous forms, each posing notable occupational risks. Therefore, a careful trade-off between benefits and risks is necessary.

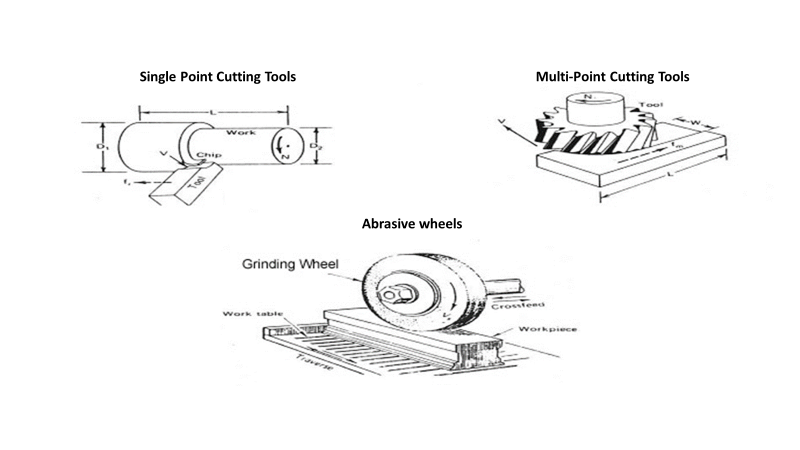

Tool Categories of Machining Processes

In machining processes, tools are categorized based on their cutting action and method. Single-point cutting tools, such as those used in turning, boring, shaping, and planning, have a single cutting edge that removes material from the workpiece. These tools are versatile and can create precise shapes and dimensions.

On the other hand, multi-point cutting tools, including those used in milling, drilling, and sawing, have multiple cutting edges that work simultaneously, allowing for faster material removal. Broaching tools are used for precision machining of complex shapes and surfaces.

Abrasive wheels, used in grinding, lapping, and honing, are abrasive tools that remove material through abrasion, creating smooth finishes and precise dimensions. Each tool category plays a crucial role in different machining operations, offering a wide range of capabilities to meet various manufacturing needs.

What is the difference between rough and finished cut?

The difference between rough and finished cuts lies in their purpose and the amount of material they remove. Roughing cuts are utilized to quickly remove large amounts of material, aiming to shape the workpiece closer to the final dimensions. These cuts are aggressive, leaving behind some material that will be removed in subsequent finishing cuts.

On the other hand, finishing cuts are used to achieve the final part dimensions, tolerances, and surface finish. They are much lighter and more precise than roughing cuts, focusing on refining the workpiece to meet the required specifications.

What are machined parts?

Machining is the process of cutting parts to specific dimensions. A machined part is a part that has undergone the machining process. Machined parts can be divided into two categories:

- Rotational parts with a cylindrical shape

- Prismatic parts (non-rotational) with block-like shapes

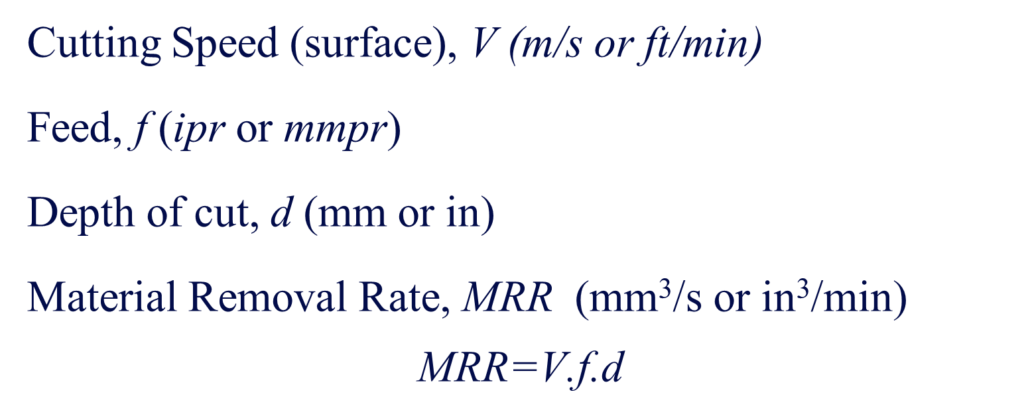

What is cutting motion in machining?

Cutting is the action of trimming away pieces of the workpiece and is normally done by a cutting tool moving in a straight direction. The three basic relative motions between the tool and the workpiece.

- Primary motion

- Secondary or feed motion

- Motion to set the depth of the cut

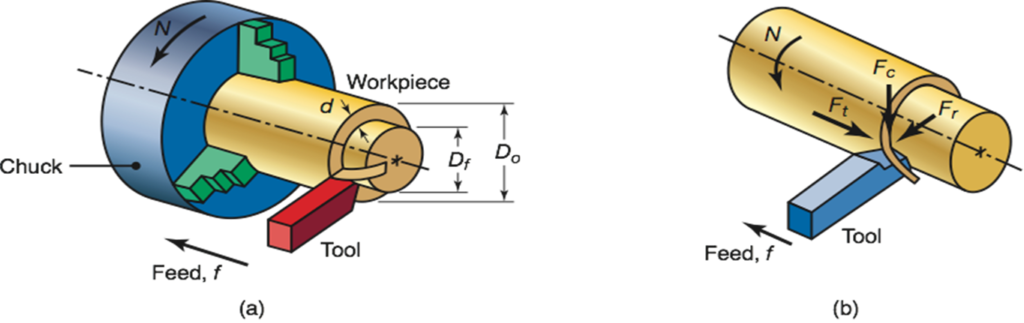

What is the turning process?

In turning, a cutting tool is fed into a rotating workpiece to create a cylindrical or conical surface that is concentric with the axis of rotation. This process is traditionally performed using a lathe, one of the oldest and most versatile conventional machine tools. The cutting tool can be angled differently to create different forms. It can be done manually or with a CNC turning machine.

There are a few types of turning operations – straight turning, taper turning, facing, and parting. Straight turning is just removing material from the outer diameter of a workpiece to make a cylindrical shape. Taper turning is when you remove material at an angle to make a conical shape. Facing is when you remove material from the end of a workpiece to make a flat surface, and parting is when you cut off a section of a workpiece. It’s used in a lot of different applications, like creating bolts and shafts for machinery.

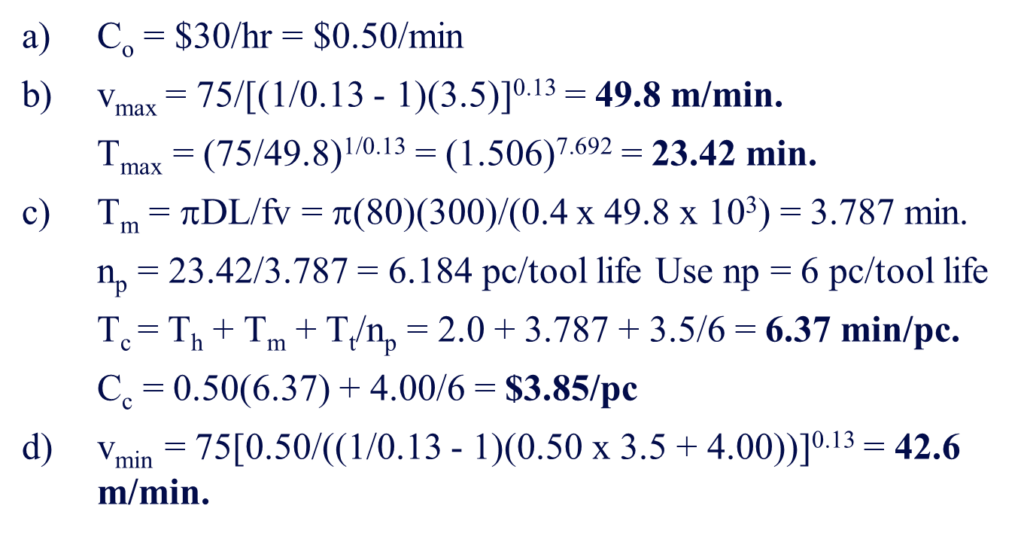

Sample Problem:

A HSS tool is used to turn a steel workpiece that is 300 mm long and 80 mm in diameter. The parameters in the Taylor equation are n = 0.13 and C = 100 (m/min) for a feed of 0.4 mm/rev. The labor rate = $19.00/hr, the burden rate is $15.00/hr, and each square ceramic insert cost $25.00. It takes 2.0 min to load and unload the workpiece 5.0 min to change tools and 1.0 minutes to index. Determine:

(a) cutting speed for maximum production rate,

(b) tool life in min of cutting,

(c) cycle time and cost per unit of product

(d) cutting speed for minimum unit cost.

What is the process of milling?

Next is milling, which is similar to turning, but instead of rotating the workpiece, a milling machine uses a rotating cutting tool with many teeth to cut away material by feeding a workpiece past it. During milling operations, material is removed from the workpiece by a rotating cutter with multiple teeth. Typically, the workpiece is fed into the rotating cutter, which remains stationary. This process achieves a high material removal rate compared to other machining operations, and it can produce a very good surface finish. However, because the cutter’s teeth intermittently engage the workpiece, the cutting is interrupted, often leading to chatter and vibration issues.

The milling process can generate complex shapes or remove material from the surface of a workpiece. There are three main types of milling operations: face milling, end milling, and profile milling. Profile milling is removing material from the surface of a workpiece to make a specific shape or contour. It’s used to create things like gears and molds.

What is the difference between face milling and end milling?

The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter and is used to make a slot or a pocket, whereas face milling is used for horizontal cutting and just removing material from the surface of a workpiece to make a flat surface.

What is face vs peripheral milling?

Both slab (peripheral) and face milling have advantages and disadvantages. Slab milling is great for removing large amounts of material from a workpiece quickly, but as a result is not very precise. Face milling, on the other hand, removes a small portion of material using the cutter’s tip which makes it more accurate and can be used to create a wider range of shapes and sizes, but it is not as fast as slab milling.

What are the two types of milling methods?

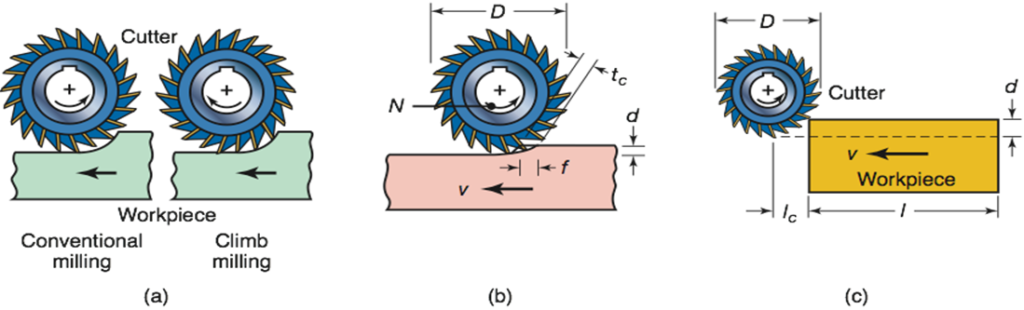

The terms up-milling and down-milling apply to all milling procedures. Up milling, also known as conventional milling, involves the cutter rotating against the direction of the workpiece feed. In climb, or down milling, the cutter rotates in the same direction as the feed rate. Despite using the same cutting tool, the method of chip formation differs entirely between the two. Additionally, the cutting forces in climb milling differ from those in down milling. Climb milling experiences extensive interrupted cutting when entering the workpiece, resulting in large impact loading, cyclic heating, and cyclic forces not present in other cutting operations.

- Up (or conventional) milling – is when the cutter rotates against the direction of the table feed

- Common method for milling

- Tendency to chatter

- Requires proper clamping

- Down (or climb) milling – is when the cutter rotates along the direction of the table feed

- Cutting force holds down the workpiece

- Requires rigid setup due to high impact of teeth on workpiece

- Not suitable for materials with surface scales (i.e. hot worked, castings)

- Results in maximum cutter life Used in finishing cuts

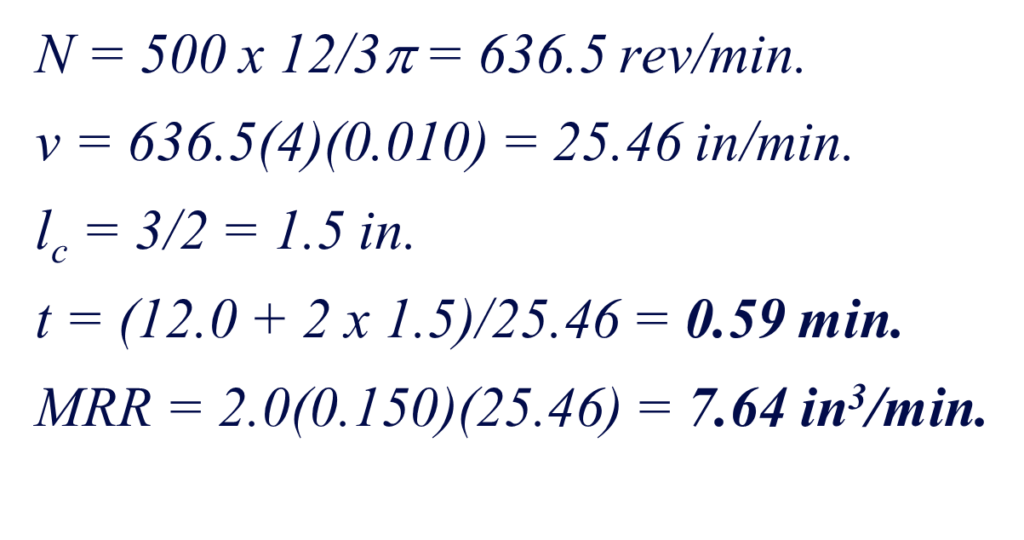

Sample Problem:

A face milling operation is performed to finish the top surface of a steel rectangular workpiece 12.0 in long by 2.0 in wide. The milling cutter has four teeth (cemented carbide inserts) and a 3.0 in diameter. Cutting conditions are: V = 500 ft/min, f= 0.010 in/tooth, and d = 0.150 in. Determine:

(a) the time to make one pass across the surface, and

(b) the metal removal rate during the cut.

What is drilling?

Drilling is the standard method for producing holes and is the most common metal cutting process. Due to the drill’s complex geometry, the process is intricate and often becomes a key bottleneck in high-volume manufacturing. Critical holes are frequently drilled in two or more passes to ensure chip removal and dimensional accuracy, with each tool penetrating only a fraction of the final depth. Boring or reaming operations often follow drilling. There are numerous types of highly specialized drilling tool designs available.

The act of drilling involves using a drill bit to create or expand a hole in a material. The main reason for drilling a hole in a workpiece is usually to enable the attachment of mechanical fasteners, such as bolts, and screws. There are a few different types of drilling operations: center drilling, spot drilling, and deep hole drilling. Center drilling is creating a small indentation at the center of a workpiece to help guide the drill bit. Spot drilling is creating a shallow hole in a workpiece to help guide the drill bit. Deep hole drilling creates a hole with high length-to-diameter ratios usually greater than greater than 10:1.

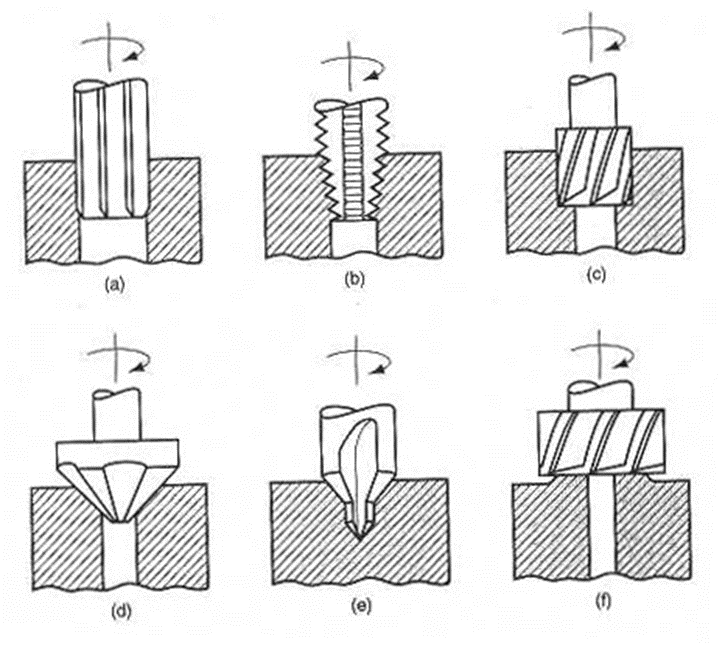

What are the types of drilling?

The 6 main types of drilling are:

- Reaming- Reaming is a specialized process used to enlarge a hole and improve its roundness and surface finish. While it is similar to boring, the design of the reaming tool is distinct, categorizing it separately. No special machines are needed for reaming; the same machine used for drilling the hole can be employed for reaming after a tool change.

- tapping -When a pre-existing hole is present, tapping is typically used to create internal threads. A hardened, specially designed threading tool is fed into a hole that was previously drilled using one of the earlier described drilling processes.

- counterboring

- countersinking

- centering

- spot facing

Conclusion

In conclusion, machining operations are a fundamental part of modern manufacturing, playing a crucial role in producing a wide range of products. From turning and milling to drilling and grinding, each operation has its unique characteristics and applications. Understanding these operations is essential for anyone interested in manufacturing or engineering, as they form the building blocks of creating precise and complex parts. As technology continues to advance, machining operations are likely to become even more sophisticated, leading to greater precision, efficiency, and innovation in the field of manufacturing.