What is a business plan for an automotive program? What is its purpose?

Describe contents of a business plan for an automotive program.

A business plan is documented, outlining a proposal for creating or forming a new product. It is typically prepared collectively by the production planning team, engineering, marketing and finance. It is an essential roadmap for business success. This document forecasts a few years in the future and outlines the route a vehicle program will have to take to meet its target. The purpose of the businesses plan is for it to act as a decision-making tool for senior management in the company. So they are able to determine whether the proposed program should be approved. A good business plan helps upper management think through all the important business issues the company will face when launching this vehicle program. Some content a business plan encompasses for an automotive program is as follows:

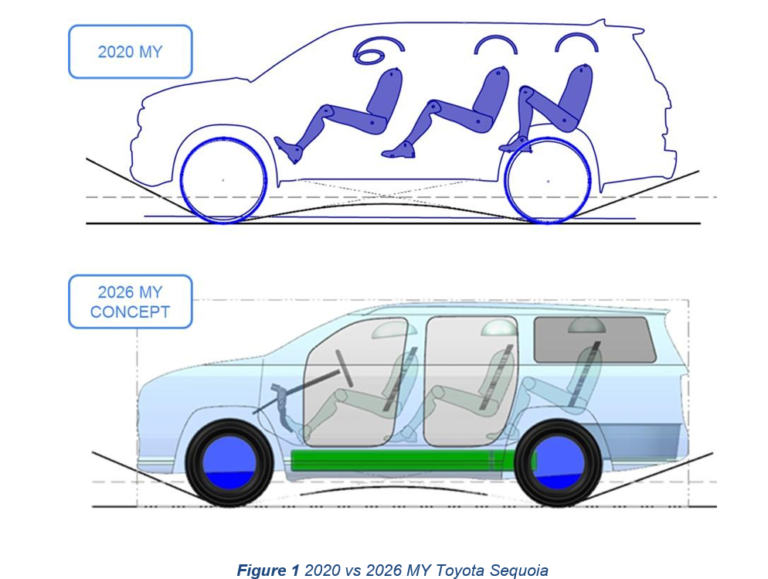

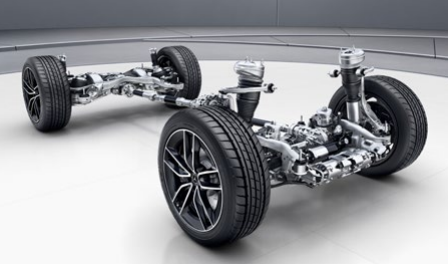

- Description of the proposed product- product configuration and model year, size class, market segment, countries of sale, powertrain, intended chassis and components, competitive data set.

- Target attribute ranking- how the product will be positioned in its market segment.

- Pugh diagram- showing product attributes and changes with respect to selected reference product.

- Dimensions, major changes and options – overall exterior and interior dimension, curve height and vehicle weight, new government regulations that might affect the program.

- Short description-vehicle proposal with several adjectives, image, stance, and styling characteristics.

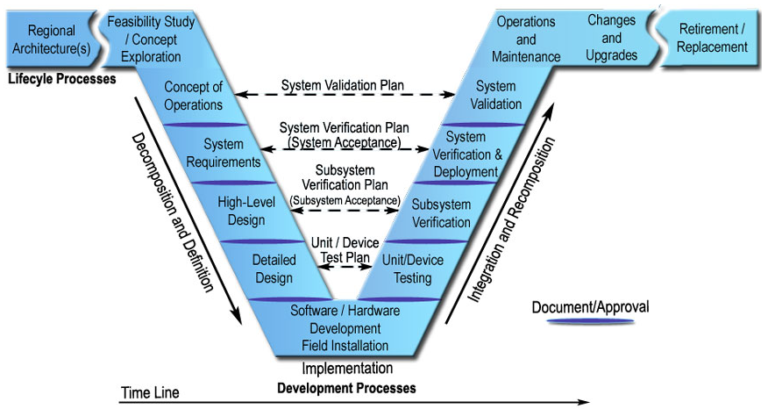

- Program schedule – kick off date, start of regular production and major vehicle life cycle events.

- Market analysis and projected sales volumes – results from market research, competitive research and sales estimates for each model in market segment.

- Organization and manpower needs- manpower required to develop, manufacture, market, and sale vehicle. Any unique expertise which might be needed.

- Make vs buy analysis and supplier plan- make vs buy analysis, supplier needed and capability

- Proposed plant location, vehicle production capacity and plant investment

- Product life cycle – estimated life span, possible product refreshments and future models and variants, recycling the plant equipment and products.

- Finance analysis-curves to estimate cumulative cost and revenue during production, anticipated funding needed, anticipated break-even point.

- Risk in the proposed product program- list of risk that might be faced during development of program.

- Program justifications- reason for undertaking the proposed plan vs other alternatives.