The Science of The Rolling Process

The Rolling process is a method used to transform metal into a thin, elongated layer by passing it between two rollers rotating in opposite directions. Rolling is often the initial process used to convert material into a finished product. In the basic rolling process, the material is passed between two rollers moving in opposite directions. This can be done hot or cold, with most materials undergoing both processes during their lifecycle.

What is the Rolling Process in engineering?

Rolling, a metalworking process, reduces slab thickness by passing it through rollers, done at various temperatures. This widely used method, found in industries like automotive and aerospace, produces sheets, plates, wires, tubes, and components. Rolling is efficient and cost-effective for large-scale production of simple shapes, ensuring consistent part quality.

What happens to the metal as it passes through the rollers during the rolling process?

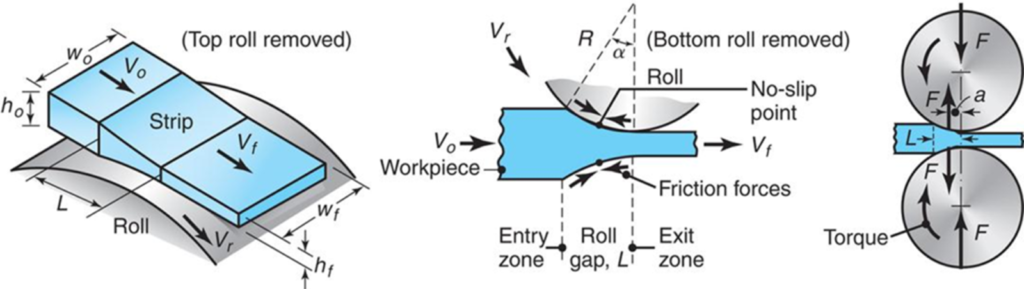

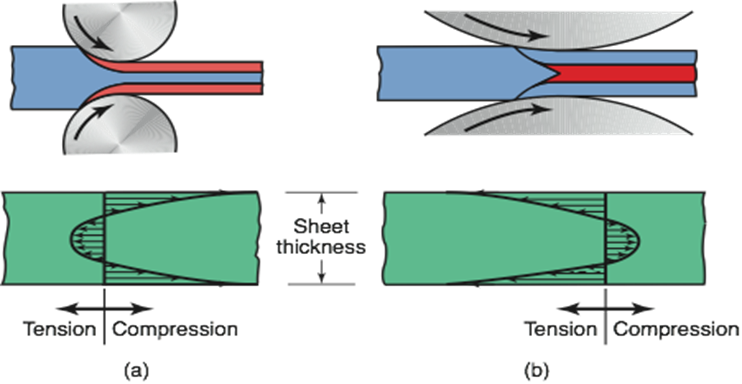

The gap between the rollers should be smaller than the thickness of the metal being worked. As the metal passes through the rollers, it experiences friction and compression, which elongates and thins it. This results in a final product with increased length and width, but decreased thickness compared to the original piece.

This reduction in thickness is known as draft, while the increase in length and width is called absolute elongation and spread, respectively. Rolling is a specialized metal-forming process used to shape large bulk materials into more detailed parts and longer cross-sectional materials. Different rolling techniques can enhance operational performance and production flow. It’s crucial for the rolling operation to match the geometry of the work component to ensure uniformity of the material and desired changes in properties due to deformation.

What is the purpose of the rolling process?

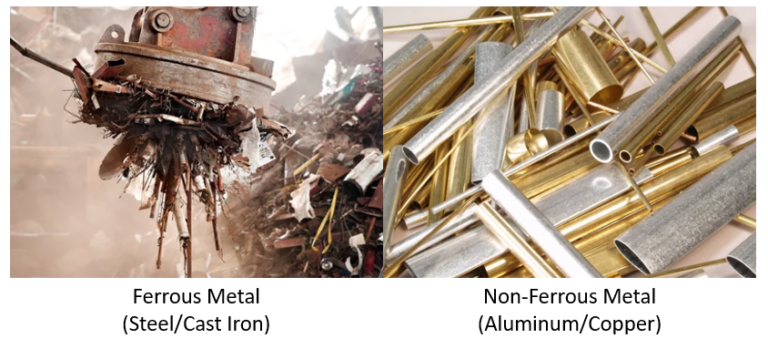

Metal rolling has dual purposes. First of all, rolling is a crucial metal-forming process, shaping over 95% of ferrous and non-ferrous metals into plates, foil, strips, bars, beams, rails, and seamless pipes. Various rolling methods include hot, cold, flat, and controlled rolling.

Additionally, it enhances the internal quality of steel. During the rolling operations, permanent deformation is achieved by exposing the material to significant compressive stresses or by passing it through a gap between two or more cylindrical rollers.

What materials are used in the Hot and Cold Rolling Process?

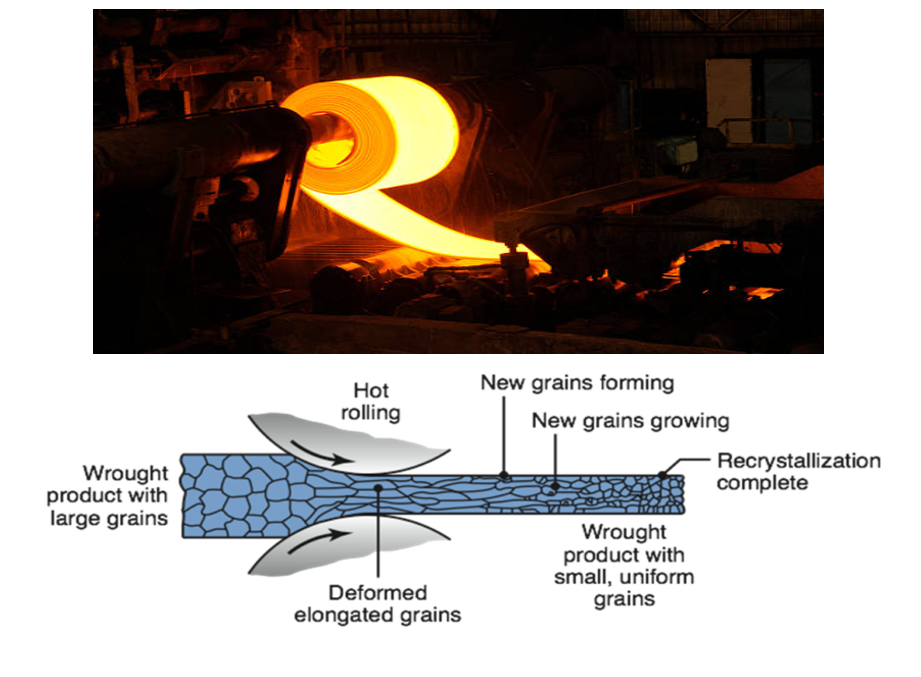

Hot rolling is a metalworking process that takes cast structures of ingots or continuous castings and converts them to a wrought structure. It does this by using high temperatures to shape the metal alloys, such as steel, aluminum, and copper. The metals are heated above their recrystallization temperature, thus changing the grain structure of metals, which makes it easier to deform. For example, for steel, the temperature is usually above 1000°C.

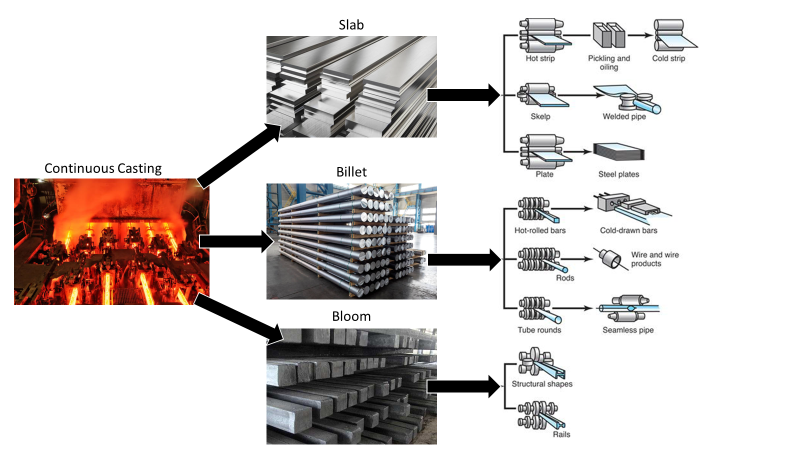

During hot rolling, thick starting stock can be transformed into blooms, billets, or slabs. The initial shape might come directly from a continuous casting process before rolling.

- A bloom has a square or rectangular cross-section, with a thickness greater than six inches (∼152 mm) and a width no greater than twice that thickness.

- A billet is smaller than a bloom, with a square or circular cross-section.

- A slab is a rectangular solid with a width greater than twice its thickness, typically further rolled to produce plate, sheet, and strip.

At this stage, cold rolling becomes practical for the reduced dimensions of plates, sheets, and strips. Types of both cold and hot rolling include sheet rolling, shape rolling, tube rolling, ring rolling, rotary tube piercing, gear rolling, roll forging, cross rolling, surface rolling, shear forming (or flow turning), and tube reducing.

What are the typical applications of hot rolled metal in various industries?

Hot rolling is used mainly to produce sheet metal or simple cross sections, such as rail tracks. Other typical uses for hot rolled metal include truck frames, automotive wheels, pipe and tubular, water heaters, agriculture equipment, compressor shells, rail car components, wheel rims, metal buildings, railroad-hopper cars, doors, shelving, discs, guard rails, automotive clutch plates.

What are metals that are trypically cold rolled?

Cold rolling, on the other hand, is a process that uses room temperature or slightly elevated temperatures to shape the material. The material is not heated above its recrystallization temperature, which makes it more difficult to deform. Cold rolling is typically used for materials such as stainless steel, titanium, and nickel alloys.

What is the mechanism of The Rolling Process?

Rolling works by plastically deforming the metal through compression by passing it between rollers rotating in opposite directions. This causes the metal to elongate and decrease in thickness. The rollers apply a force (F) and torque (T) to the metal, causing it to deform in the direction of the force. Usually, there is a negligible increase in width (Wf), so the decrease in thickness results in an increase in length. The friction force between the metal and the rollers also plays a crucial role in the rolling process.

How do you calculate forward slip in rolling?

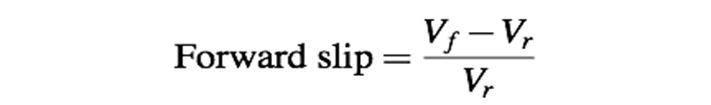

Forward slip is the relative difference between the surface speed of the rollers and the surface exit speed of the strip metal being rolled. It is an important parameter in rolling because it affects the quality of the final product. Forward slip can be calculated using the equation:

where vr is the tangential roll velocity, vf is the final work velocity

How do you calculate the rolling load?

Rolling is a steady-state metal-forming process

- Draft (d) is the reduced thickness

- d=to–tf=Dt

- Constant Volume

- towoLo=tfwfLf

- Constant volume flow rate

- towovo=tfwfvf

where:

- to initial thickness

- tf final thickness

- Lo initial length

- Lf final length

- wo initial width

- wf final width

- vo entrance velocity

- vf exit velocity of the rolled product

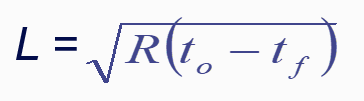

Contact length (L) =

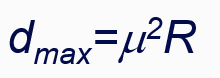

Maximum Reduction (dmax) =

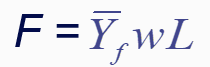

Rolling Force (F) =

Rolling Power (P) =

where P is power requirement, N is rev/min (rev/sec), F is rolling force, and L is contact length

Types of rolling techniques used in manufacturing

There are several different types of rolling methods used in modern manufacturing, each with its own advantages and disadvantages. Some of the most common rolling operations include:

- Roll bending/slab spread used to produce cylindrical or conical shapes

- Ring rolling – used to create seamless rings for use in bearings, gears, and other applications

- Profile rolling/shape rolling is used to make shapes with a specific cross-section

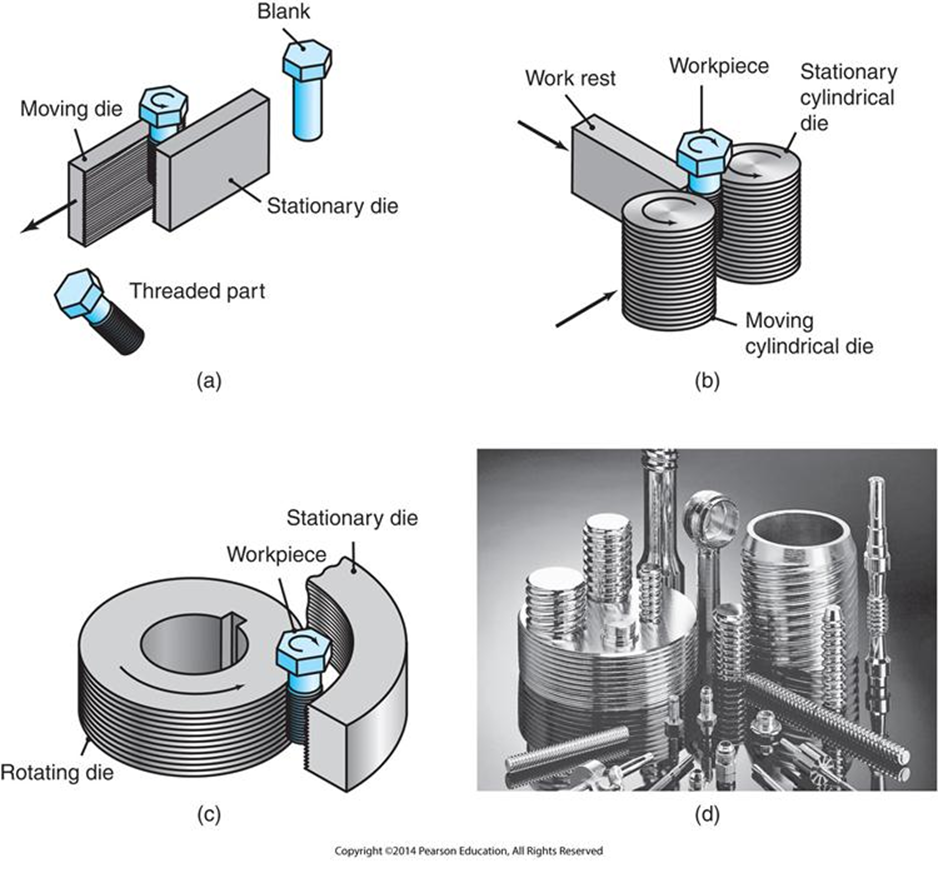

- Thread rolling- This process is used to produce threads on bolts and screws.

What is roll bending vs roll forming?

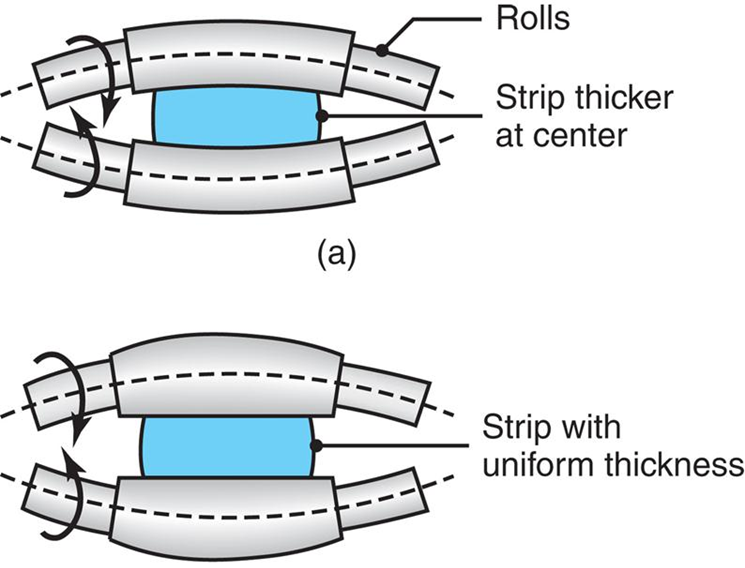

Roll bending, or slab spread, forms metal sheets into curves, cylinders, and cones by passing them between rolls. It offers precise shaping, strength, and durability, but is slower and less energy-efficient than other methods.

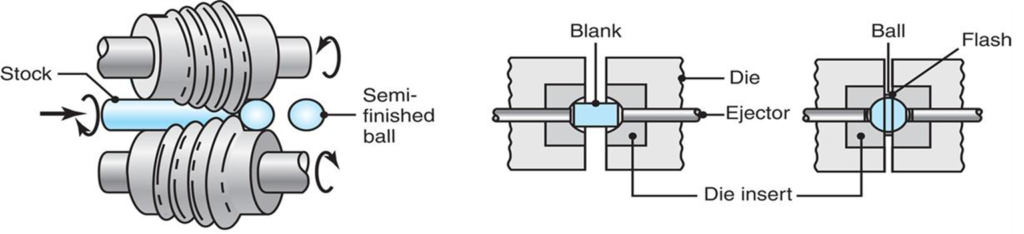

What is the manufacturing process of steel balls?

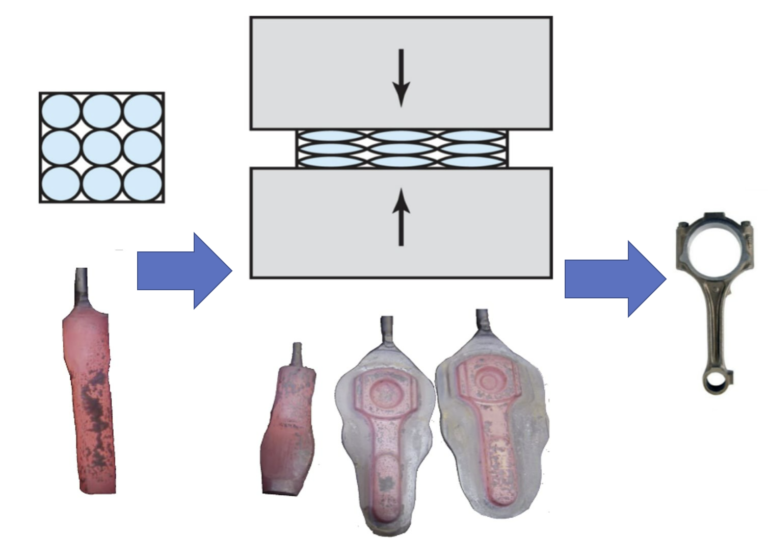

There are three types of steel ball manufacturing processes: casting, forging, and steel ball roll forming. The steel ball roll forming process involves passing a metal billet between some rollers, which apply pressure to transform the billet into a spherical shape. The advantages of steel ball roll forming include the ability to produce consistent, high-quality balls with a smooth surface finish. However, the process can be slow and requires significant energy to operate, making it less efficient for small-scale production.

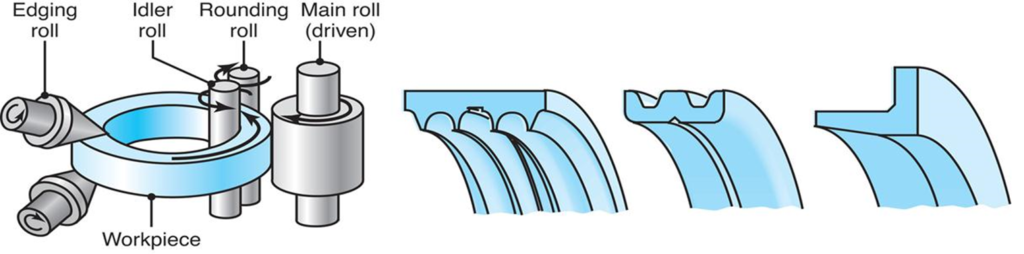

What is Ring Rolling?

Ring rolling is a specialized rolling process for the production of rings of various sizes and shapes. This process involves passing a headed and pierced metal ring between two or more rotating dies (rollers), which apply pressure to shape and deform the material. This results in a thickness reduction of the ring but as a result, it increases the part diameter. The advantages of ring rolling include the ability to produce high-strength, durable rings with precise dimensions and surface finish. However, the process is limited to producing rings with uniform thickness, making it less suitable for producing rings with varying cross-sections.

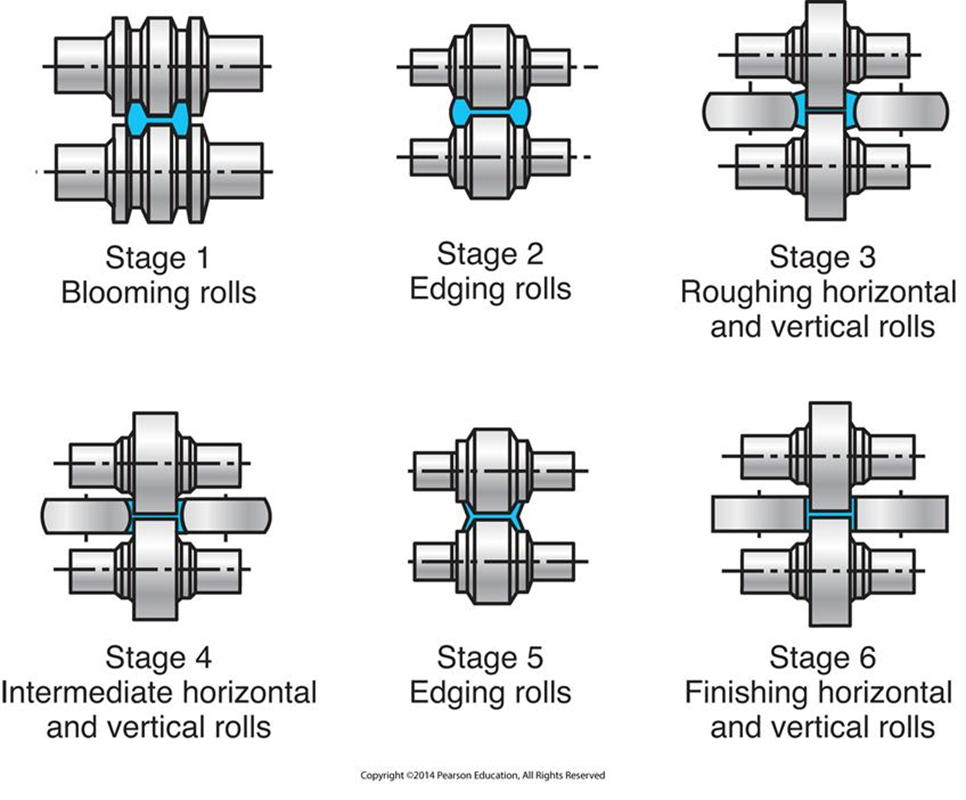

What is shape rolling used for?

Structural shape rolling, also known as shape rolling or profile rolling, is a metal forming process that bends or deforms a continuous casting or ingots to a desired shape while maintaining a constant cross-section. Shape rolling is used to produce various cross-sectional shapes, such as bars, channels, angles, and I-beams, by passing the workpiece through a rolling mill. The advantages of shape rolling include:

- High production rate: Shape rolling can produce high volumes of metal components at a relatively high speed.

- Cost-effective: Shape rolling is a cost-effective metal forming process as it requires less material and energy than other forming processes, such as forging or casting.

- Consistent quality: Shape rolling produces components with consistent quality and properties due to the controlled rolling process and the use of high-quality rolls.

- Wide range of shapes: Shape rolling can produce a wide range of cross-sectional shapes with various dimensions and properties to meet specific requirements.

What are the advantages of thread rolling?

Thread rolling is a metal forming process used to produce threads on a workpiece by pressing it against a set of dies that have a thread profile. Thread rolling is widely used to produce high-quality threads on bolts, screws, and other fasteners.

Some of the advantages of thread rolling include:

- Increased strength: Thread rolling produces threads with higher strength and fatigue resistance due to the cold-working process that improves the grain structure and surface finish of the threads.

- Improved accuracy and fine surface finish: Thread rolling produces threads with better dimensional accuracy, consistency, and surface finish than other thread-forming processes, such as thread cutting or tapping.

- The economy of scale: Thread rolling can produce threads faster than thread cutting, resulting in higher production rates and lower costs.

- Reduced material waste: Thread rolling produces threads with less material waste than thread cutting as it does not require the removal of excess material (metal chips).

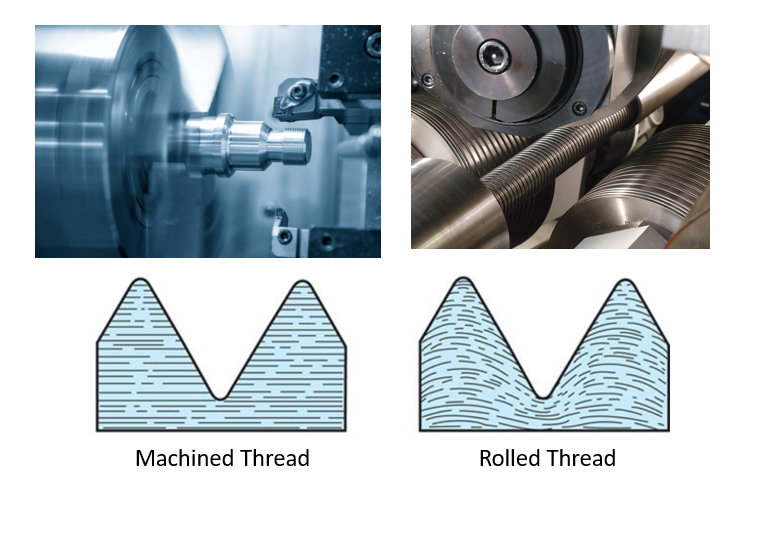

What is the difference between thread rolling and thread cutting?

Thread rolling and thread cutting are different methods of creating threads on a workpiece. Cut threads (machined threads) involve removing material from the workpiece to create threads, while rolled threads involve deforming the material on the workpiece to create threads.

Thread cutting can either be machined in a lathe via turning or manually done using a tap and die set. In both instances, the material is removed from the workpiece to create the thread geometry. This can be done using a tap for internal threads or a die for external threads. The cutting tool is typically made of high-speed steel and must be properly aligned with the workpiece to produce accurate threads. Thread cutting is a slower process than thread rolling, and it can produce chips and burrs that must be removed.

In thread rolling, a hardened steel die with thread profiles is pressed against the surface of the workpiece. The material on the workpiece is then deformed and displaced to create the threads. Thread rolling is a faster process than thread cutting and does not produce chips or burrs. It also results in a stronger thread, as the material is compressed rather than removed.

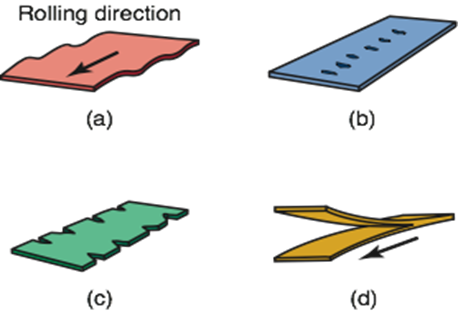

What are the defects in the rolling process?

Defects in the rolling process can occur due to several reasons, including improper alignment of the rollers leading to uneven rolling, excessive forward slip, improper or uneven heating, and excess quenching. Some typical defects in flat rolling include cracks along the edges of the part workpiece known as edge cracks, surface marks, non-uniform thickness, wavy edges, zipper cracks in the center of the strip, and alligatoring.

The reason for these defects is due to the residual stresses that develop in rolling with small-diameter rolls or at small reductions in thickness per pass. Residual stresses can also develop in rolling with large-diameter rolls or at high reductions per pass.

Defects in rolling can be broadly categorized into general and operational defects. General defects stem from imperfections in the initial and final products of the rolling process. On the other hand, operational defects result from the deformation or deflection of the rolls during rolling, leading to defects in the final products. This article focuses on rolling operations as a metal-forming practice in industrial manufacturing.

It examines trends in rolling operations, compares the performance of different processes, and discusses the implications and applications of rolled products. The research emphasizes the importance of understanding the relationship between human and machine handling, equipment management, material handling, and the identification of rolling defects to enhance operational performance in future industrial manufacturing.

Conclusion

In conclusion, the rolling process stands as a cornerstone in modern metalworking. Facilitating the transformation of raw materials into a myriad of products essential to our daily lives. Through careful orchestration of forces and temperatures, this process crafts everything from sheets and plates to intricate profiles with precision and efficiency.

Understanding the science behind rolling illuminates its immense industrial significance and paves the way for continued advancements in metal-forming technologies. As we delve deeper into the complexities of rolling, we unlock new possibilities for innovation, ensuring its enduring relevance in the ever-evolving manufacturing landscape.

Itís hard to come by knowledgeable people about this subject, but you sound like you know what youíre talking about! Thanks